Milwaukee Tool 6185-20 User Manual

Page 3

4

5

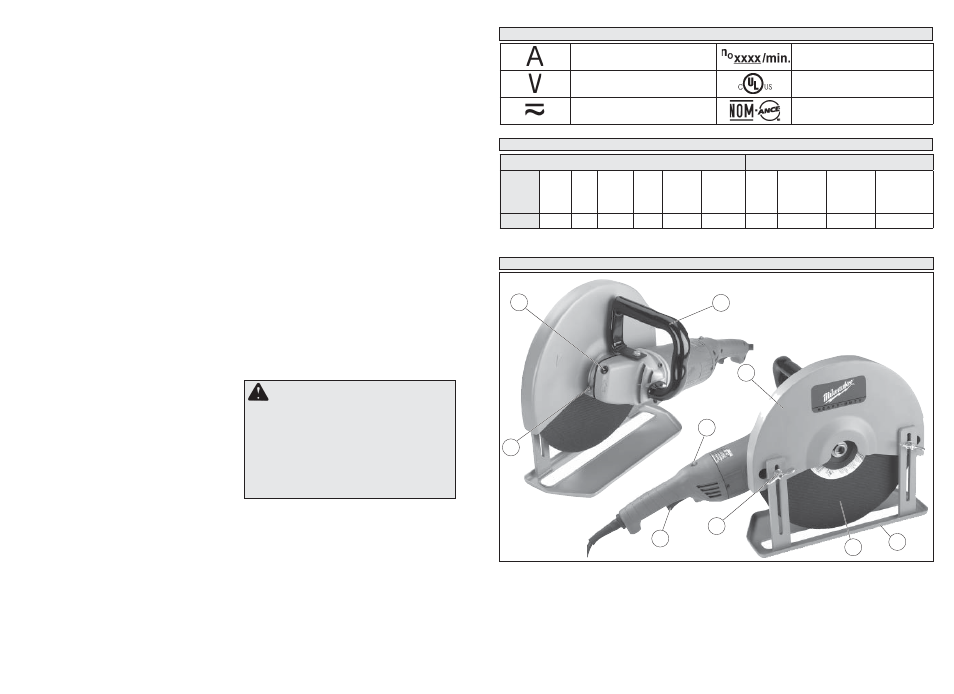

FUNCTIONAL DESCRIPTION

SYMBOLOGY

SPECIFICATIONS

Cut-Off Machine Capacities

Abrasive Cut-Off Wheel Capacities

Cat. No.

Wheel

Size

RPM

Volts

AC/DC Amps

Spindle

Size

Cutting

Capacity

Wheel

Size

Min.

Wheel

RPM

Rating

Wheel

Thickness

Wheel

Arbor

Hole Size*

6185-20

14"

4600

120

15

5/8"-11

4-7/16"

14"

5400

1/8"

1" or 20 mm

Safety Warnings Specifi c for Abrasive Cutting-

Off Operations:

• Use only wheel types that are recommended

for your power tool and the specifi c guard

designed for the selected wheel. Wheels for

which the power tool was not designed can not

be adequately guarded and are unsafe.

• The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed to-

wards the operator. The guard helps to protect

operator from broken wheel fragments and ac-

cidental contact with wheel.

• Wheels must be used only for recommended

applications. For example: do not grind with

the side of cut-off wheel. Abrasive cut-off wheels

are intended for peripheral grinding, side forces

applied to these wheels may cause them to shatter.

• Always use undamaged wheel fl anges that are

of correct size and shape for your selected

wheel. Proper wheel fl anges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel fl anges.

• Do not use worn down wheels from larger

power tools. Wheel intended for larger power tool

is not suitable for the higher speed of a smaller tool

and may burst.

Additional Safety Warnings Specifi c for Abra-

sive Cutting-Off Operations:

• Do not jam the cut-off wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases

the loading and susceptibility to twisting or bind-

ing of the wheel in the cut and the possibility of

kickback or wheel breakage.

• Do not position your body in line with and

behind the rotating wheel. When the wheel, at

the point of operation, is moving away from your

body, the possible kickback may propel the spin-

ning wheel and the power tool directly at you.

• When wheel is binding or when interrupting a

cut for any reason, switch off the power tool

and hold the power tool motionless until the

wheel comes to a complete stop. Never attempt

to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

• Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully reenter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted

in the workpiece.

• Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kick-

back. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge

of the workpiece on both sides of the wheel.

• Use extra caution when making a “pocketcut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes,

electrical wiring or objects that can cause kickback.

Additional Safety Warnings

• Maintain labels and nameplates. These carry

important information. If unreadable or missing,

contact a MILWAUKEE service facility for a free

replacement.

• WARNING: Some dust created by power sanding,

sawing, grinding, drilling, and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are spe-

cially designed to fi lter out microscopic particles.

WARNING

To reduce the risk of injury,

avoid inhalation of dust generated by grind-

ing and cutting operations. Exposure to dust

may cause respiratory ailments. Use approved

NIOSH or OSHA respirators, safety glasses or

face shields, gloves and protective clothing.

Provide adequate ventilation to eliminate dust,

or to maintain dust level below the Threshold

Limit Value for nuisance dust as classifi ed

by OSHA.

* The tool is supplied with both a 1" fl ange nut and a 20 mm fl ange nut. To ensure the wheel is properly secured,

always use the fl ange nut that matches the wheel arbor hole size.

1. Trigger

2. Overload protector

3. Guard

4. Shoe assembly

5. Abrasive cut-off wheel

(not included)

6

7

9

8

3

1

2

5

4

6. Handle

7. Spindle lock

8. Wing nuts

9. Guard bolt

Amps

No Load Revolutions per

Minute (RPM)

Volts

Underwriters Laboratories, Inc.,

United States and Canada

Alternating Current/Direct Current

Mexican Safety Standards