Milwaukee Tool 5337-21 User Manual

Page 4

6

7

OPERATION

1. Hammering only.

For use with "hammering

only" accessories. Use this setting for chiseling.

2. Chisel adjustment. Use this setting to adjust

the angle of the chisel blade in relation to the tool.

With a chisel mounted in the tool, twist the chisel

to the desired angle. Then, rotate the action

selector to the "hammering only" setting for use.

Electronic Feedback Control Circuit

These hammers have an Electronic Feedback

Control Circuit (EFCC) which helps improve the

operation and life of the tool.

Feedback Control

The electronic speed control circuit allows the tool

to maintain constant speed and torque between

no-load and load conditions.

Soft Start

The Soft-Start feature reduces the amount of torque

reaction to the tool and the user. This feature gradu-

ally increases the motor speed up from zero to the

speed set by the speed control dial.

Selecting Speed

The speed control dial on these hammers allows

the user to adjust the rotating speed (RPM) and the

impact rate (BPM) of the tool.

To change the speed, set the speed control dial to

the desired setting.

• Lower speeds provide more control when starting

holes and reduce 'spalling' on breakthrough. Spall-

ing occurs when pieces of material chip off around

the drilled hole on breakthrough. When chiseling in

soft or brittle materials, use lower speeds to reduce

damage to surrounding areas of the material.

• Higher speeds provide faster penetration when

drilling and chiseling in demolition work.

Selecting Action

Cat. No. 5337-20

The cat. no. 5337-20 demolition hammer is for

"hammering-only". No rotation is available. Only

chisels and other "hammering-only" accessories

should be used.

Cat. No. 5339-20

The cat. no. 5339-20 demolition hammer is for

"hammering-only". No rotation is available. The

action selector is used to select the action:

WARNING

To reduce the risk of injury,

wear safety goggles or glasses with side

shields. Unplug the tool before changing

accessories or making adjustments.

NOTE: To engage the hammering mechanism,

maintain pressure on the bit/chisel. When pressure

is released, hammering stops.

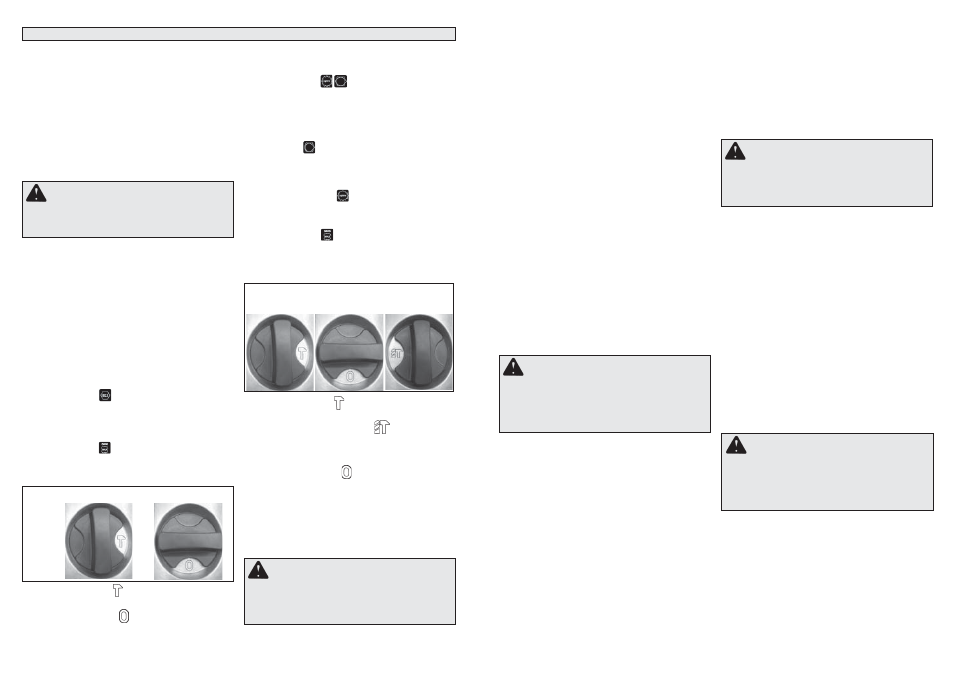

Fig. 3

Chisel Adjustment

Hammering Only

Cat. No. 5340-20

The cat. no. 5340-20 rotary hammer has "hammer-

ing-only" and "hammering with rotation", depending

on the type of shank inserted into the tool.

For "hammering-only": Insert a chisel or other

"hammering-only" accessory with a 3/4" Hex with

21/32" Round

shank into the nose of the tool (see

"Inserting Bits and Chisels"). The rotational drive

mechanism will run but not engage with the chisel,

resulting in "hammering-only" action.

For "hammering with rotation": Insert a drill or

coring bit with a spline

shank into the nose of the

tool (see "Inserting Bits and Chisels"). The rotational

drive mechanism engages with the bit, resulting in

"hammering with rotation" action.

Cat. No. 5342-20

Cat. no. 5342-20 rotary hammer has "hammering-

only", "hammering with rotation", and "chisel

adjustment" settings. The action selector is used

to select the action:

1. Hammering only.

For use with "hammering

only" accessories. Use this setting for chiseling.

2. Hammering with rotation.

Use this setting

for drilling holes with drill bits. Do not use "ham-

mering with rotation" when using chisels or other

"hammering-only" accessories.

3. Chisel adjustment. Use this setting to adjust

the angle of the chisel blade in relation to the

tool. With a chisel mounted in the tool, twist the

chisel to the desired angle. Then, rotate the ac-

tion selector to the Hammering only setting for

use.

NOTE: To engage the hammering mechanism,

maintain pressure on the bit/chisel. When pressure

is released, hammering stops.

Starting and Stopping the Tool

1. To start the tool, pull the trigger.

2. To stop the tool, release the trigger.

Fig. 4

Hammering

Only

Hammering

with Rotation

Chisel

Adjustment

WARNING

To reduce the risk of injury,

when using chisels or other hammering-only

accessories in cat. no. 5342-20, the action

selector must be set to the "hammering only"

position.

Locking the Trigger (Cat. No. 5337-20, 5339-20 only)

The lock button on the demolition hammers holds

the trigger in the "On" position for continuous use.

1. To lock the trigger, hold in the lock button while

pulling the trigger. Release the trigger.

2. To unlock the trigger, pull the trigger and release.

The lock button will pop out.

Cold Hammering

If the hammer is stored for a long period of time or

at cold temperatures, the lubrication may become

stiff and the tool may not hammer initially or the

hammering may be weak. If this happens:

1. Insert a chisel into the tool.

2. Pull the trigger and apply the chisel against a

scrap piece of concrete.

3. Turn the tool On and Off every few seconds.

After 15 seconds to 2 minutes, the tool will start

hammering normally. The colder the hammer is,

the longer it will take to warm up.

Operator Force

These hammers feature the Vibration Isolation

System to provide the operator with comfort without

sacrifi cing power or performance. The motor hous-

ing is suspended independently from the switch

handle. Insulating elements absorb vibration when

hammering and drilling.

Ideal operator force compresses the handle slight-

ly and allows the tool to work aggressively while the

handle provides maximum vibration dampening.

Excessive operator force compresses the handle

too far and reduces the vibration dampening. Users

will be able to feel the difference and should adjust

the force to the handle accordingly.

Hammering Only

1. Insert a chisel or other "hammering only" ac-

cessory into the tool (see "Installing Bits and

Chisels").

2. Position the tool on the workpiece.

3. Grasp both handles fi rmly (trigger handle and

either the spade handle or straight handle).

4. Pull the trigger. Always hold the tool securely

using two handles and maintain control.

5. Use only enough pressure to hold the tool in

place, engage the hammering mechanism, and

prevent the tip of the chisel from wandering.

This tool has been designed to achieve top

performance with only moderate pressure. Let

the tool do the work.

NOTE: To engage the hammering mechanism,

maintain pressure on the bit/chisel. When pres-

sure is released, hammering stops.

6. When chiseling or chipping, hold the tool at an

angle to the work area. For best performance,

work from a corner or close the edge of the work

and break off a small area at a time.

WARNING

Applying greater pressure

does not increase the tool's effectiveness.

If the applied working pressure is too high,

the shock absorber will be pushed together

making vibration to the handle noticeably

stronger.

If a hammer iron gets stuck:

1. Unplug the tool.

2. Pull out bit lock and rotate it 180°.

3. Pull the tool off of the stuck accessory.

4. Remove the accessory from the workpiece.

Hammering with Rotation

1. Insert a drill or coring bit into the tool (see "Install-

ing Bits and Chisels").

2. Position the tool on the workpiece.

3. Grasp both handles fi rmly (trigger handle and

straight handle).

4. Pull the trigger. Always hold the tool securely

using the straight handle and trigger handle and

maintain control.

5. Use only enough pressure to hold the tool in place,

engage the hammering mechanism, and prevent

the tip of the bit from wandering. This tool has

been designed to achieve top performance with

only moderate pressure. Let the tool do the work.

When pressure is released, hammering stops.

6. When drilling deep holes, the speed may begin

to drop off. Pull the bit partially out of the hole

while the tool is running to help clear dust.

NOTE: Do not use water to settle the dust since

it will clog the bit fl utes and tend to make the bit

bind in the hole.

If a bit binds:

If the bit should bind, a built in, nonadjustable slip

clutch prevents the bit from turning when the tool

is held or braced securely. If this occurs

1. Turn off and unplug the tool.

2. Free the bit from the workpiece.

3. Clear debris from the hole.

4. Begin drilling again.

Using Rotary Percussion Core Bits

Core bits are useful for drilling larger holes for

conduit and pipe. MILWAUKEE Heavy-Duty Core

Bits have heat-treated steel bodies with durable

carbide tips. These core bits are specially designed

for fast, accurate drilling with combined hammering

and rotary action.

1. Clean and lubricate the threads on the adapter

and core bit to make later removal easier. Screw

the threaded end of the adapter into the rear of

the core bit.

2. Push the guide plate onto the pointed end of the

center pin. Insert the center pin and guide plate

assembly into the core bit. Be sure the small end

of the center pin is securely placed into the hole

in the center of the core bit (Fig. 5).

WARNING

To reduce the risk of injury,

hold or brace securely. Always be prepared

for drill reaction when bit binds, when hole

becomes clogged, when striking embedded

materials, and during hole breakthrough.

WARNING

Use MILWAUKEE core bits

Cat. No. 48-20-5125 through 48-20-5165. Do

not use LHS (Large Hole System) Components

with rotary hammers 5340-20 and 5342-20. The

bits could fail, breaking apart at the threaded

stud and causing injury and property damage.