Replacement parts, Warning, General operation of relief valve – Leslie Controls NYC Heat Exchanger User Manual

Page 14: A. recirculation pump, D. blend valve

Page 14 of 25

-

Accepted for use in food processing industries (if

applicable)

-

Removes scale, slag, tarnishes, and hard water

deposits

-

Easily rinsed out of system

-

No objectionable or corrosive fumes

CERTIFICATION

Heat exchangers are designed and fabricated in accordance

with ASME Code Sec. VIII, Div.1 for symbols “U” and

“UM”. Heat exchangers are CSA approved and have

obtained CRN in Canadian provinces.

Copies of above certificates are available upon request.

1.

GENERAL OPERATION OF

RELIEF VALVE

PRESSURE RELIEF VALVE IS NATIONAL

BOARD CERTIFIED. TEMPERATURE

STEAM RATED

ANS Z21.22 RELIEF VALVES CONFORMS

TO H.U.D./F.H.A. REQUIREMENTS.

Discharge from relief valve shall be conducted to a

suitable place for disposal when relief occurs by

installation of a drain line to any open drain. Make sure

water in drain cannot freeze and cause a stop-up. Relief

line must be such that relief valve outlet and drain line will

drain dry.

Do not use reduced couplings or restrictions to install drain

line to valve discharge.

This valve protects a water system from over-pressure. It

will automatically shut off after providing such protection.

If valve fails to shut off, check for excessive pressure

and/or heat input control operation.

REPLACEMENT PARTS

A. RECIRCULATION PUMP

(ref Figure 6)

Pump replacement parts are :

•

Impeller

•

Impeller seal

•

Body Gasket

Do not attempt to replace motor bearings, replace the

motor as a whole unit. Refer to manufactures specific IOM

for further details.

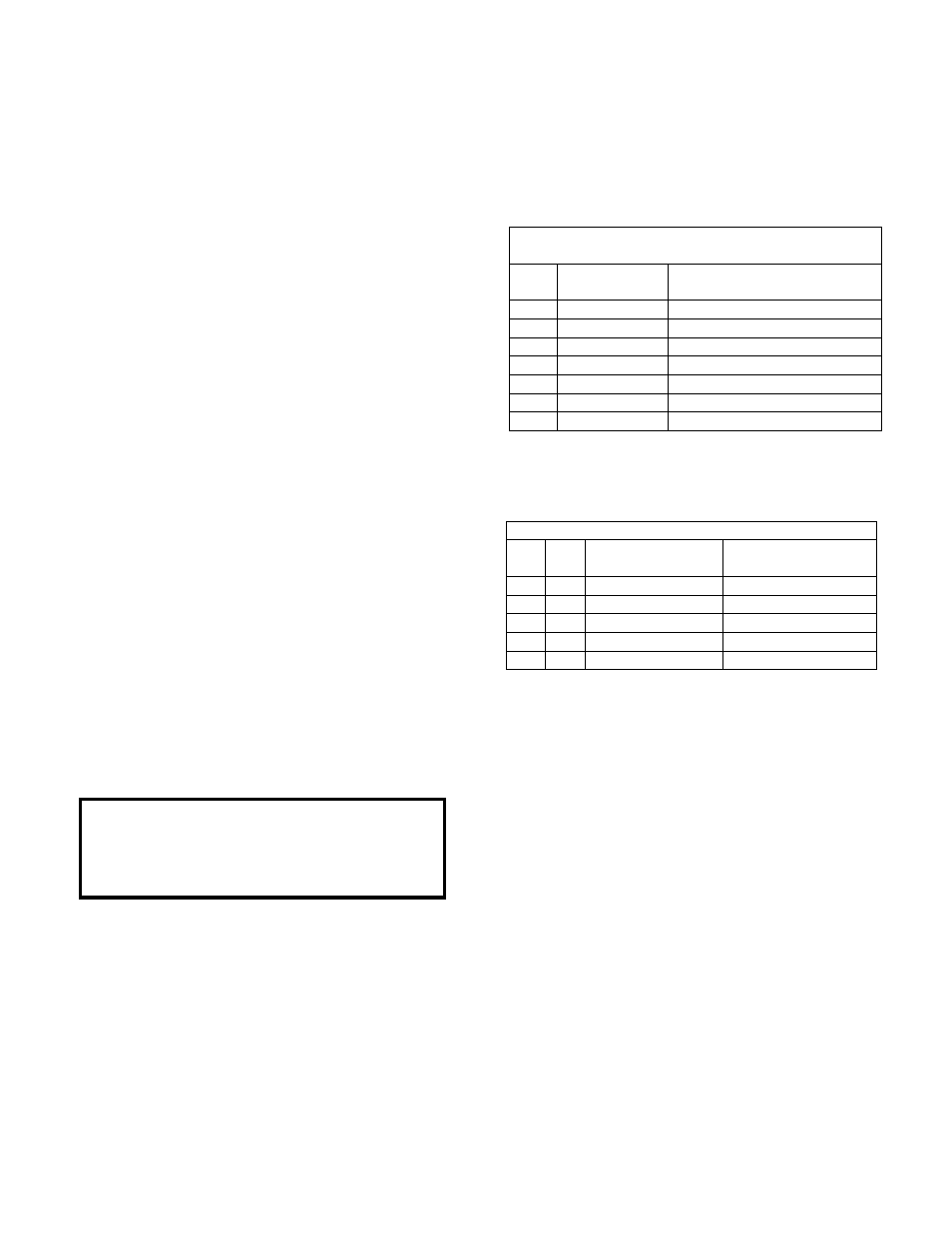

D.

BLEND VALVE

Service Parts For Model BO

Ref

No

Part No

Description

3

9585L001

Seat, Bolted-In

4

1182

Sleeve

5

11132L050

Capscrews

6

11133

Lockwasher

7

1183

Element O-Ring, Buna-N

8

1096X(TEMP) Element Assembly

9

761

O-Ring

Blend Valve temperature ranges are:

150 degrees F for the first valve

130S degrees F (S = Special 120 degree F unit)

Service Kit No. 9167X(Temp.) Standard Element

Ref

No

Qty Description

Part No.

3

1

Element

1125X(Temp.)

4

1

O-Ring

1205

5

1

O-Ring

277L145

6

1

O-Ring

11080L001

7

1

O-Ring

11079L001

No adjustments are ever required on thermostatic valves.

Once installed a thermostatic valve will provide years of

trouble-free service. It is entirely self-contained, and there

are no external bulbs or lines to become damaged or

broken. There are no packing glands to tighten and no

parts to oil. Temperature is permanently set at factory and

requires no further adjustment.

Operating temperature can be changed only by changing

temperature

element

assemblies

which

is

easily

accomplished by unbolting housing. Element assemblies

are all interchangeable within each lettered valve series.

Larger valves in “B” and “H” series contain multiple

element assemblies in one housing. This means that a

temperature element assembly will fit any size

thermostatic valve housing in that series.

WARNING!

This product contains a chemical known to the State

of California to cause cancer, birth defects or other

reproductive harm.