Leslie Controls NYC Heat Exchanger User Manual

Page 13

Page 13 of 25

rain). During transportation, ensure that they are not

exposed to mechanical damages.

STARTUP

To prepare heat exchanger for operation, it should initially

be:

Mounted properly

Filled with working fluids

Deaerated

All connections checked for leaks

During startup, first open valves, then start pump of

heated medium followed by opening cycle of heating

medium. Valves should be opened gradually in order to

achieve a steady increase in flow and pressure. Pressure

increase/decrease should not exceed 72 psi/min (0.5

Mpa/min).

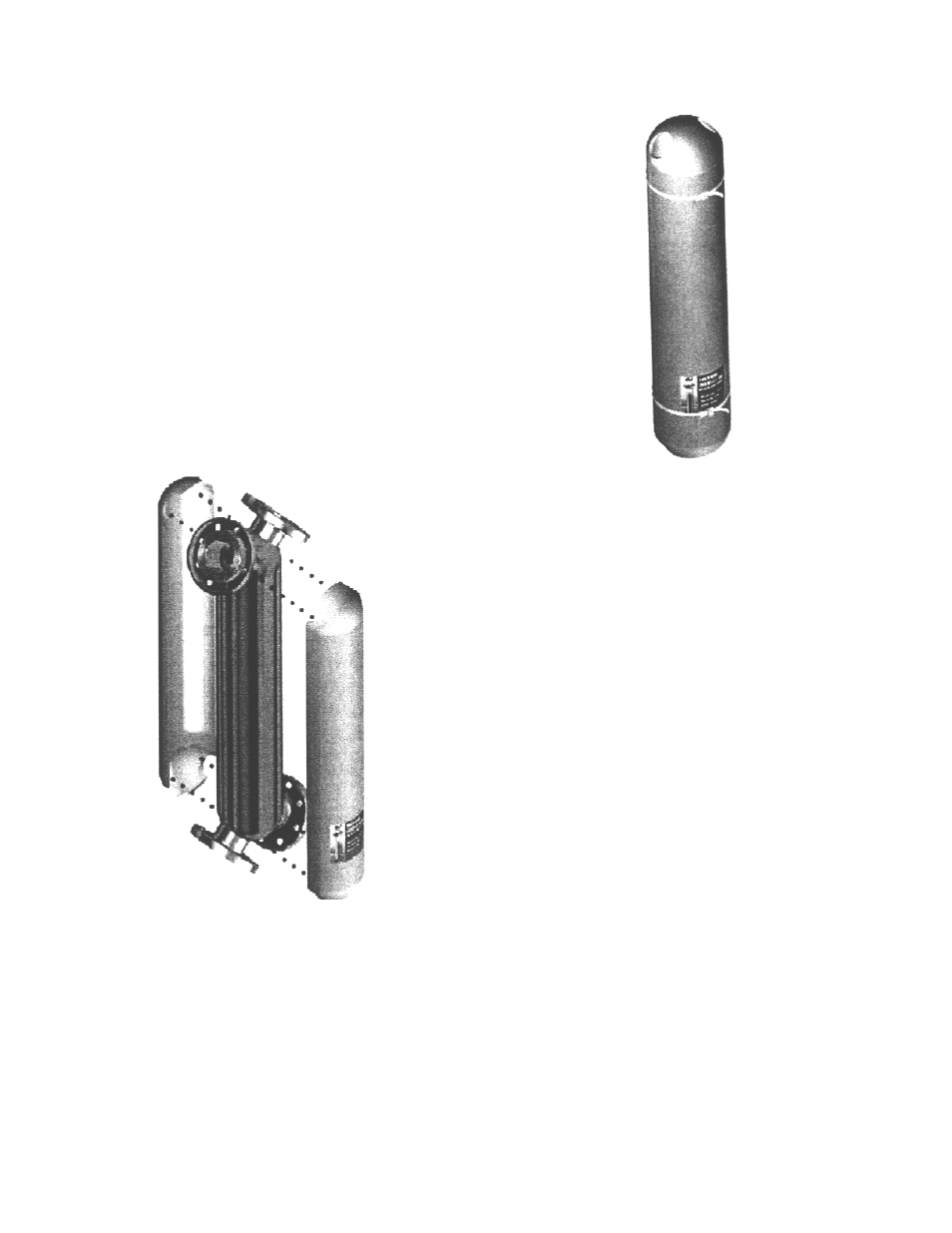

Figure 11 - Complete Installation Diagram

Figure 12 - Insulation tied with straps

Insulation is mainly used to reduce heat loss, and also

offers operator some degree of personal protection from

hot surface of unit. Insulation should be designed for

temperatures up to 130°C.

CLEANING

Heat exchangers are cleansed by flushing units with

fluids which do not react with stainless steel.

Dirt deposit in heat exchanger will result in an increase in

pressure drop, lower temperature difference in heated

medium or a higher exit temperature on heating medium

side. Flushing can be done without removal of heat

exchanger from system.

Following fluids are prohibited for use as a flushing agent:

Hydrochloric acid up to 0.1% concentration

Solutions which contain MCI

Chlorides (MgCl

2

NaCl between 0.01 – 1%, CuCl up to

1%, CaCl

2

from 5% to saturation, KCL, MgCl

2

)

Any fluid which should deposit alkaline residue or

phosphorous

Cleaning solutions are easily accessible at businesses

carrying chemical cleaning agents for heat exchangers or

tubing and piping applications. As a guideline to

purchasing cleaning solutions, check for following

products data:

-

Compatibility with stainless steel