Warning, I. general operation of heat exchangers, J. general operating principle – Leslie Controls NYC Heat Exchanger User Manual

Page 11

Page 11 of 25

I.

GENERAL OPERATION OF

HEAT EXCHANGERS

Heat exchangers are designed to transfer heat between

steam and water at various temperatures, fluid flows, and

pressures.

CONSTRUCTION FEATURES

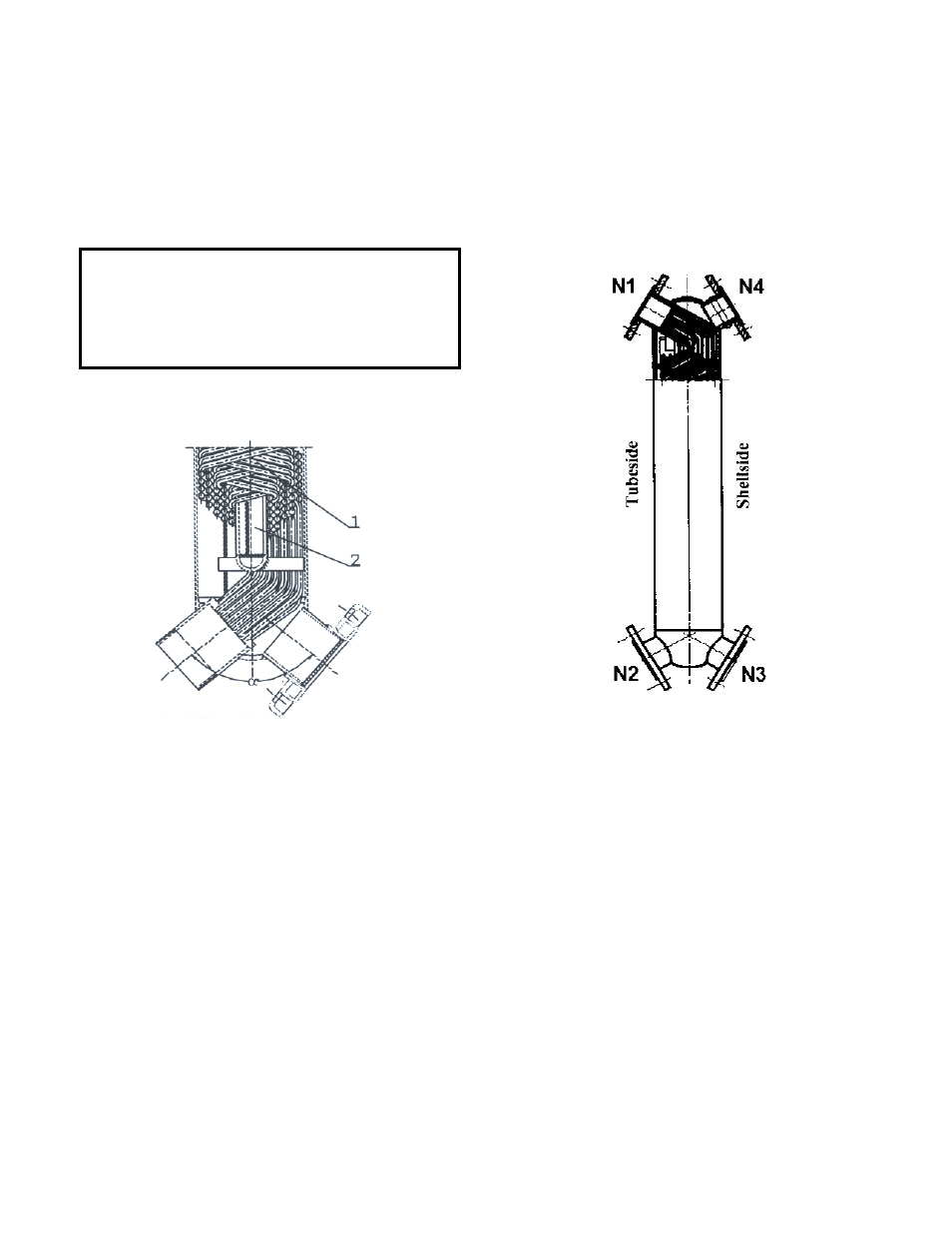

Figure 7 - Cross Section

Heat exchangers are designed and fabricated as a single

unit with non-removable parts. Cylindrical shell encloses

a tube bundle which consists of circular layers of helically,

corrugated tubes. Each layer flows in opposite direction to

layers surrounding it in a criss-cross manner. Tube bundle

has

perforated

bottom,

which

are

welded

near

connections. Both ends of cylindrical shell are enclosed

within hemispherical heads.

Each heat exchanger has a total of four (4) symmetrically

located connections, two on each hemispherical head. One

pair of opposing connections is connected to tube side

while other pair is connected to shell side.

J. GENERAL OPERATING

PRINCIPLE

A heat exchanger is a device in which heat is transferred

from one flowing fluid to another. Shell and Tube heat

exchangers are most common type of heat exchangers.

These heat exchangers are counter flow units, which from

a thermodynamic point of view extract more heat from a

given fluid stream than order common types of heat

exchangers.

Heating medium flows through tubes. Thermal energy is

transferred through tube walls. Total heat load is

dependent on flow parameters of fluid.

Figure 8 – Flow Distribution in Heat Exchangers

WARNING!

FLUSH HEAT EXCHANGERS

WITH FRESH CLEAN WATER EVERY SIX

MONTHS. An inspection and maintenance log must

be maintained.