LAARS Pennant PNCV (Sizes 200, 300, 400) - Install and Operating Manual User Manual

Page 37

LAARS Heating Systems

Page 36

Pennant 200, 300, 400

Page 37

If short cycling occurs in a water heater

application, it is probably caused by undersized

piping between the water heater and the storage tank

or by some other factor that restricts proper water

flow through the water heater. The cause should be

determined and corrected.

8.5 High Gas Consumption

Appliances operating with an improper air/fuel

ratio are very inefficient and consequently, have

very high gas consumption. Because efficiency is

high when the CO

2

is high (or O

2

is low), appliances

operating with low CO

2

or high O

2

(especially LP

appliances) consume more gas. Adjust the CO

2

or O

2

for optimum efficiency. If no combustion analyzing

equipment (CO

2

or O

2

) is available then a proper

adjustment of the air/fuel ratio (CO

2

or O

2

) cannot be

accomplished. The CO

2

should be 8% at high fire for

natural gas and 9.2% at high fire for LP. To check the

CO

2

, first verify that the supply gas pressure is within

5 to 13 in. w.c. (1.2 to 3.2 kPa). With the Pennant

running with all stages firing, set the air box pressure

to 1.8 in. w.c. (0.42 kPa) (as a starting point), by

adjusting the air shutter(s) at the intake of the fan(s).

Check the CO

2

, and adjust the air shutters if further

adjustment to the CO

2

is needed.

8.6 Troubleshooting Pennant Controls

The field wiring board along with the diagnostic

LEDs can be used to troubleshoot the Pennant

controls. Terminals on the field wiring board are

provided as test points and allow troubleshooting of

most Pennant control functions from a single location.

The terminals are identified in the Ladder Wiring

Schematic (Figure 14).

Certain control elements may be connected in the

field to the field wiring board. In addition to the ladder

wiring schematic, refer to the Connection Diagram

(Figure 13) to verify that field connections have been

made correctly.

The Pennant temperature control and ignition

control both have fault indicators. The temperature

control fault codes are shown in Table 12. The ignition

control fault codes are shown in Table 13.

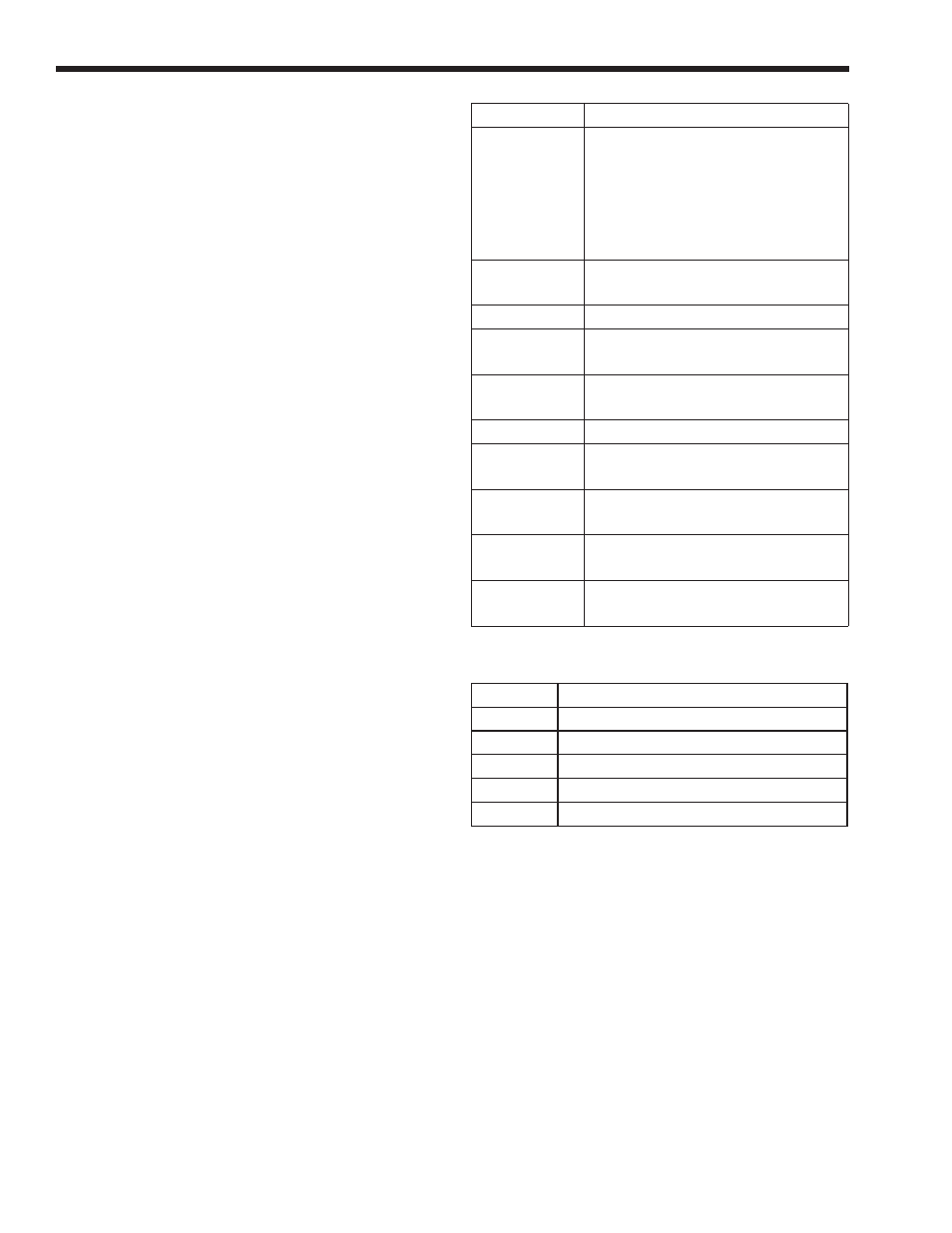

Fault Code

Description

NoA

No acknowledged call-for-heat

signal received (K1 energizes and

the contacts close, but 24V is not

shown on the downstream side of

the K1 contact) (This code is normal

when operating in "Remote" mode.)

I-F

Ignitor fault signal received from

ignition control

AFF

Air flow fault

FLE

Flame error – flame detected with

no call for heat

Loc

Ignition lockout signal received from

ignition control

Ito

Ignition time-out

P1H

RT1 sensor shorted or high out-of-

range temperature signal received

P1L

RT1 sensor open or low out-of-

range temperature signal received

P2H

RT2 sensor shorted or high out-of-

range temperature signal received

P2L

RT2 sensor open or high out-of-

range temperature signal received

Table 12. Fault Codes.

LED State Indication

Steady On Control Fault

1 Flash

Air Flow Fault

2 Flashes Flame Attempt With No Call For Heat

3 Flashes Ignition Lockout

4 Flashes Burner On

Table 13. Ignition Control LED Description

SECTION 9.

Replacement Parts

Only genuine Laars replacement parts should be used.

9.1 General Information

To order or purchase parts for the Laars Pennant,

contact your nearest Laars dealer or distributor. If

they cannot supply you with what you need, contact

Customer Service (see back cover for address,

telephone and fax numbers).

9.2 Parts List