Laars heating systems – LAARS Pennant PNCV (Sizes 200, 300, 400) - Install and Operating Manual User Manual

Page 22

LAARS Heating Systems

Page 20

Pennant 200, 300, 400

Page 21

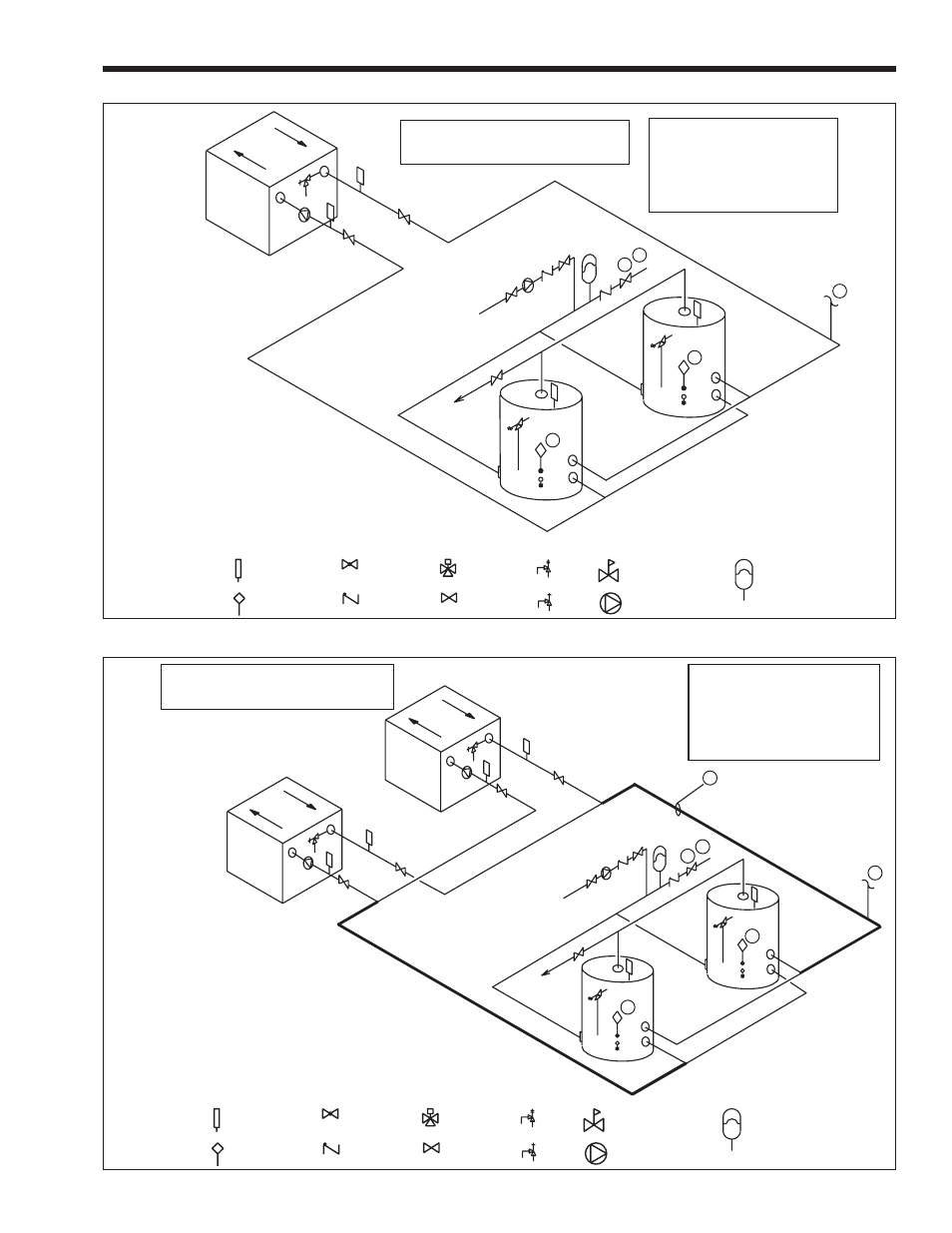

Figure 11. Water Heater Piping — One Heater, Multiple Tanks.

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING, CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

NOTES:

5. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT

JOB SITE

1. OPTIONAL CWMU & RECIRC. LINE LOCATION.

2. LOCATE PENNANT DHW SENSOR OR REMOTE AQUASTAT

WELL IN LOWER 1/3 OF TANK.

3. BACK FLOW PREVENTER MAY BE REQUIRED. CHECK LOCAL CODES.

4. THERMAL EXPANSION TANK MAY BE REQUIRED. CHECK LOCAL CODES.

RECIRC.

CWMU

SUPPL

Y

WATER CATEGORY

GRAIN HARDNESS PER GALLON

PPM / 17.1 = Grains Per Gallon

KEY:

S = SOFT

N = NORMAL

H = HARD

1 THROUGH 7.5

7.6 THROUGH 17

OVER 17

2

2

3

4

1

CHECK VALVE

THERMOMETER

TEMPERATURE

SENSOR

GLOBE VALVE

EXPANSION TANK

3-WAY VALVE

VALVE

PRESSURE REDUCING

VALVE

PUMP

PRV

TPRV

Figure 12. Water Heater Piping — Multiple Heaters, Multiple Tanks.

CAUTION: THIS DRAWING SHOWS SUGGESTED

PIPING CONFIGURATION AND VALVING, CHECK

WITH LOCAL CODES AND ORDINANCES FOR

ADDITIONAL REQUIREMENTS.

NOTES:

6. CAUTION: PUMP SIZING MUST BE BASED UPON WATER HARDNESS AT

JOB SITE

1. OPTIONAL CWMU & RECIRC. LINE LOCATION.

2. LOCATE PENNANT DHW SENSOR OR REMOTE AQUASTAT

WELL IN LOWER 1/3 OF TANK.

3. BACK FLOW PREVENTER MAY BE REQUIRED. CHECK LOCAL CODES.

4. THERMAL EXPANSION TANK MAY BE REQUIRED. CHECK LOCAL CODES.

5. COMMON PIPING, SHOWN WITH HEAVY LINES, MUST BE SIZED

FOR MAXIMUM COMBINED HEATER FLOW RATE.

RECIRC.

CWMU

SUPPL

Y

WATER CATEGORY

GRAIN HARDNESS PER GALLON

PPM / 17.1 = Grains Per Gallon

KEY:

S = SOFT

N = NORMAL

H = HARD

1 THROUGH 7.5

7.6 THROUGH 17

OVER 17

2

2

3

4

1

5

CHECK VALVE

THERMOMETER

TEMPERATURE

SENSOR

GLOBE VALVE

EXPANSION TANK

3-WAY VALVE

VALVE

PRESSURE REDUCING

VALVE

PUMP

PRV

TPRV