LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 7

Endurance

Page 7

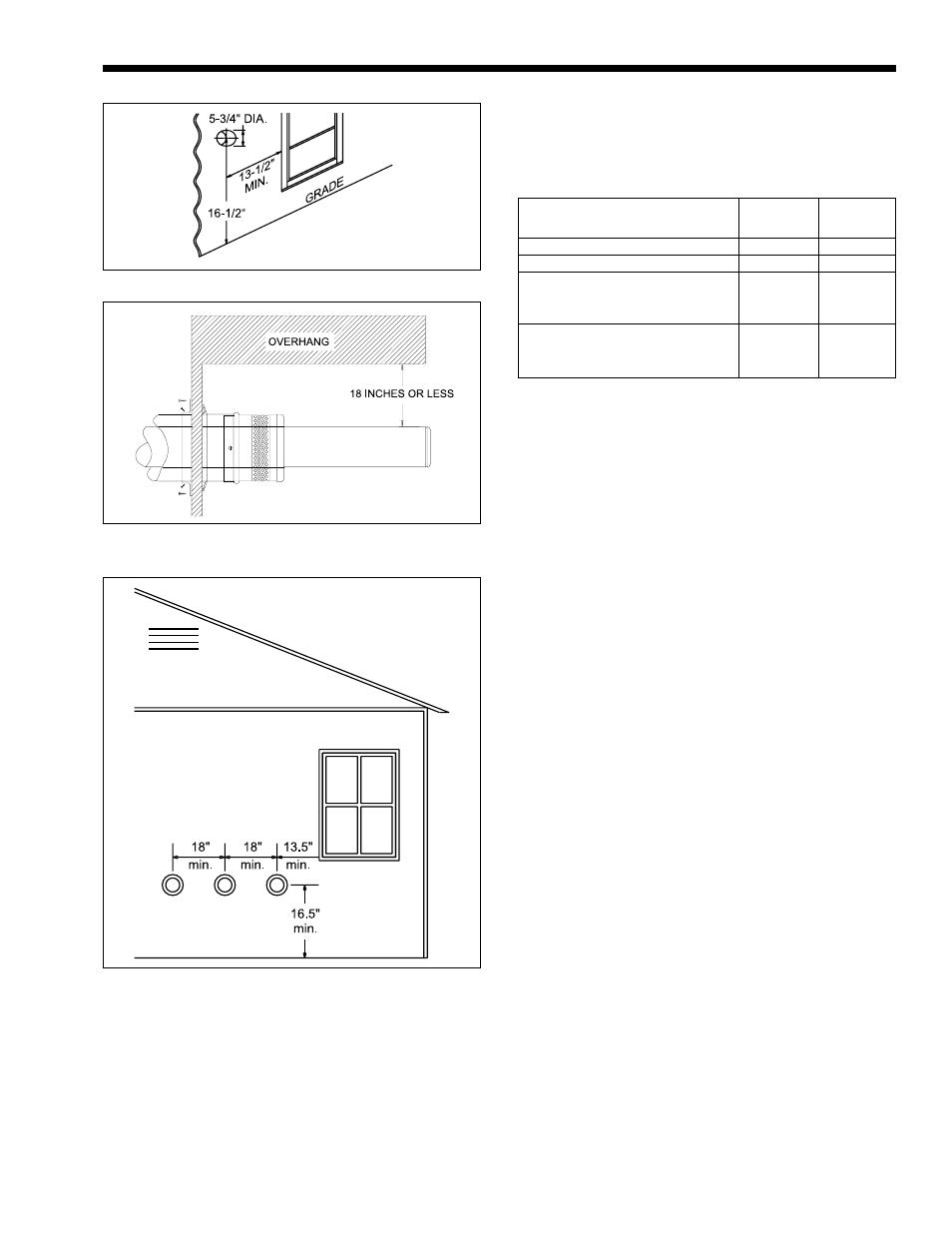

When appliances are used, the concentric vent

terminals must be at least 12" apart, edge-to-edge (see

Figure "term").

Do not locate the vent terminal where blockage

by snow is a possibility, or where flue products could

strike against building materials and cause

degradation. If the vent terminal location chosen is

less than 18" below an overhang, the 3" vent pipe

must extend to the outside edge of the overhang (see

Figure 6).

2.4 Stainless Steel Single Pipe Horizontal

and Vertical Vents - Category IV

Stainless steel special gas Vent listed to U.L.

Standard 1738 and U.L.C. Standard 636 may be used

Figure 7. For Appliances Certified as Direct Vent.

Figure 8. Typical vent installation with 18" or less

overhead clearance to outside.

Minimum clearance from

combustibles (vent)

3"

76mm

Max. flue gas temp.

325°F

163°C

Max. vent pressure

1.5" WC

0.4kPa

Max. equivalent ft. of venting

3"

76mm

(any combination of horizontal

diameter

diameter

or vertical)

50 equiv. ft.

15.2m

Max. equivalent ft. of venting

100 equiv. ft.

30.5m

(any combination of horizontal

or vertical)

4" diameter 102mm dia.

Table 2. Appliance Venting Design Data.

Figure 9. Multiple Concentric Vent Clearances.

to vent all models. Vent pipe and fittings are

manufactured to these standards by HeatFab, Inc.

under the trade name of Saf-T Vent

®

and by Z-Flex

™

under the trade name of Z-Vent. Follow the Special

Gas Vent manufacturer's instructions regarding design,

location and assembly of the vent system.

The appliance may be vented with any number of

elbows or fittings provided that the maximum

equivalent feet of venting is not exceeded. Elbows

(90°) in the vent system shall be considered to be 5

equivalent feet (1.5m). When vented with special gas

vent, the appliance must not be common vented with

any other appliance.

For applications requiring vertical venting

through a roof, the above limitations apply. Vertical

vents greater than 7' (2.1m) in length must offset a

condensate trap tee p/n 2400-358 adjacent to the

appliance. Utilize vent cap p/n 2400-370 to terminate

vertical venting.

2.5 Air Source For Combustion

(when not direct vented)

When using Category IV venting methods the

appliance draws all combustion air through its top and

from the adjacent space. When locating the appliance

in unconfined spaces in buildings, infiltration may be

adequate to provide air for combustion and ventilation.

However, in buildings of unusually tight construction,

or when locating the appliance in a confined space,

additional air should be provided and the following

guidelines must be followed.

1.

If the space is in a building of unusually tight

construction, air should be obtained from

outdoors, or from spaces which freely connect

with outdoors.

2.

For boilers in confined rooms, two permanent

openings shall be provided - one within 12"

(305mm) of the ceiling, and one within 12"

(305mm) of the floor of each room. Each opening

shall be at least one square inch (6.5 sq. cm) per