LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 23

Endurance

Page 23

The EBP modulating combination boiler will

start from any of three input signals: (a)T-T closure

for space heating. (b)A demand for domestic hot

water, signaled by water flow activation of the water

flow switch. (c)A call for heat from the minimum

tank temperature sensor at 158°F (tank charge mode).

In tank charge mode the red LED located below the

green LED on the PCB will be lit. In modes (b) and

(c) which are priority modes, the internal anti-

condensing valve will be closed. On a T-T call for

heat the valve will remain closed until the priority

modes are satisfied.

[Service note: as with the thermostatic union in

the EDP/EDN models, the anti-condensing valve

prevents condensation on the combustion chamber coil

and must be in the closed position when the coil inlet

(F6) indicates a temperature below 130°F].

8.2 Trouble Shooting - Fault Codes

The Endurance boiler is controlled by a Pactrol

integrated boiler control (PCB) which provides eight

fault codes with eight memories. To obtain fault

messages press-in on the message center fault button

until the first fault code (FLI) is displayed.

If a thermistor error occurs, it will appear on the

LED upon power-up. The memory does not need to

be accessed. Memory fault codes are for error

history only. All thermistor faults will show as “F”

codes on the LED, and will never cause the LED to

read “LO”. (Note that the unit is shipped with error

codes already in memory, and an error code that is

shown in memory upon start-up of a new unit is from

manufacturing testing.)

The last recorded fault will appear e.g. F-4 (flow

thermister faulty - open or shorted). The control will

then sequence through all eight memories, indicating

alternately the fault number and the fault code (FL1,

F-?; FL2, F=?; …, FL8, F=?). The fault number in

fault code FL1 is the most recent fault.

8.2.1 Fault Code Identification

The following eight fault codes may be observed:

F-

Error corrected, control in auto reset time

period (10 seconds)

F-0 No fault has occurred

F-1 Error occurred reading fault logic of main

control

F-2 Over heat thermostat has operated

(open circuit)

F-3 Fan fault

F-4 Flow temperature sensor faulty

(open or short circuited)

F-5 Tank temperature sensor faulty

(open or short circuited) (Combi unit only)

F-6 Return temperature sensor faulty

(open or short circuited)

8.2.2 Fault Correction (see also Fault

Trees in this Section)

F-1 Switch off boiler and restart. If F-1 repeats,

replace PCB

F-2 The overheat thermostat (safety limit)

opens at 230°F. Observe boiler operation if

the boiler shuts off before the

indicates

225°F (107°C) replace safety limit. If the

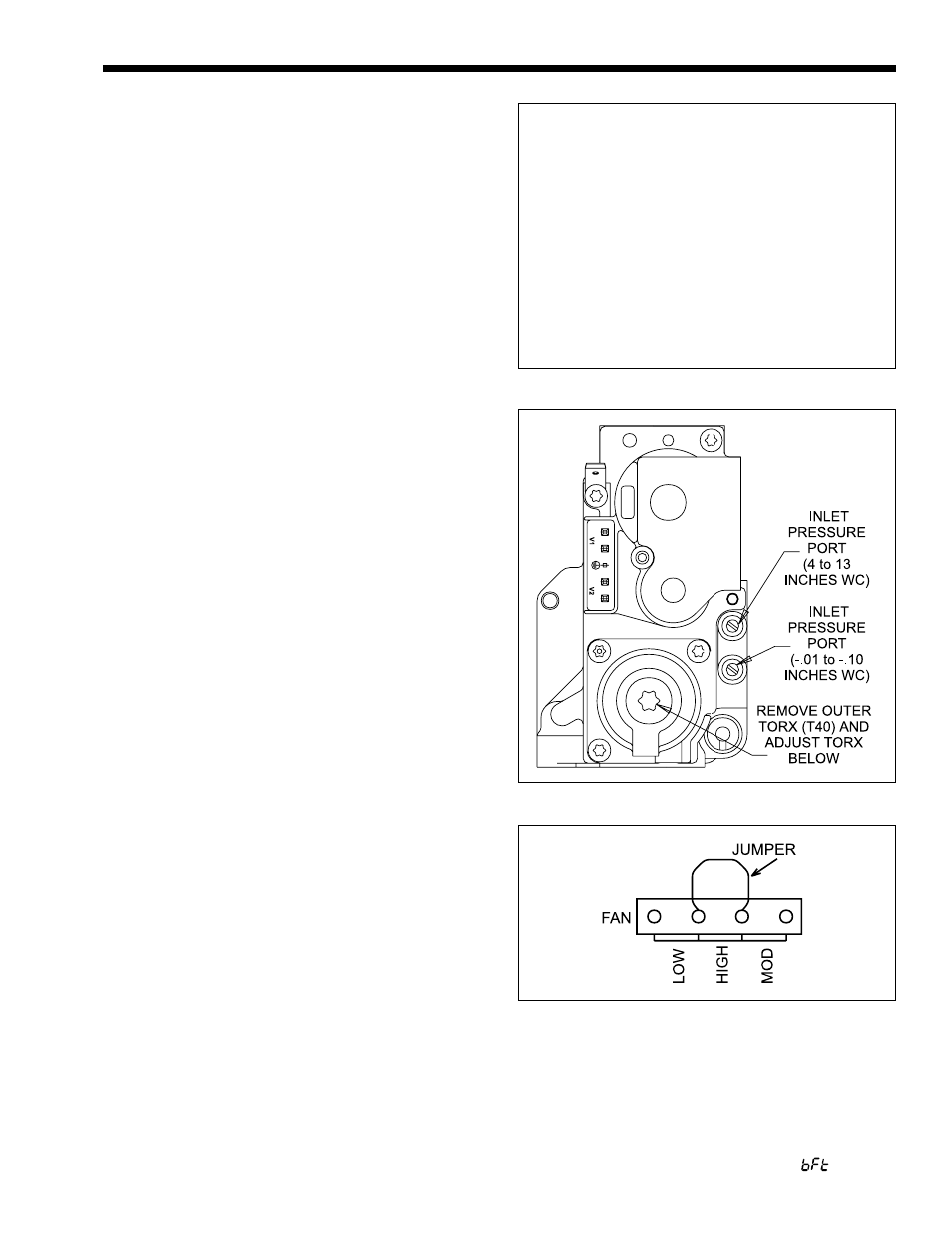

Figure 29.

Table 4. EBP/EDP 175.

MEASUREMENTS AT HIGH FIRE

NATURAL GAS

% CO

2

9.0 - 9.6

MAX INPUT

175,270

BTU/H

OFFSET

(-0.01 to -.10)

IN W.C.

LP GAS

% CO

2

9.7 - 10.1

MAX INPUT

175,270

BTU/H

OFFSET

(-0.01 to -.10)

IN W.C.

Figure 30. Jumper Wiring for Test and Calibration.