LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 17

Endurance

Page 17

Glycol products must be maintained properly in a

heating system, or they may become ineffective.

Consult the glycol specifications, or the glycol

manufacturer, for information about specific products,

maintenance of solutions, and set up according to your

particular conditions.

SECTION 5.

Electrical Connections

5.1

Electrical Connections

All electrical wiring must conform to local codes

and/or the National Electric Code or Canadian

Electrical Code, Part 1.

The unit must be electrically grounded in

accordance with the requirements of the authority

having jurisdiction or, in the absence of such

requirement, with the National Electrical Code.

ANS/NFPA No. 70 latest edition, or the CSA Standard

C22.1 “Canadian Electrical Code, Part 1.”

Single pole switches, including those of safety

control and protective devices must not be wired in a

grounded line.

All electrical connections are made in the field

wiring box which is located on the top of the appli-

ance, behind the right hand side of the control pod.

NOTE: All internal electric components have

been pre-wired. No attempt should be made to connect

electric wires to any other location except the wiring

box as described below.

1.

Main power: Connect a fused 120 volt supply

(15 amp) to the main power switch (see

Figure 20) (hot leg is connected directly to

switch). Neutral leg to white wire. Ground wire

water. The display will show [ICE] during this time.

This feature is intended to assist in protecting the

boiler from freezing conditions, and does not help to

protect any other part of the heating system. This

feature will only help when there is power to the boiler

and when the internal water flow components in the

Endurance are working properly. This feature will not

be able to prevent freezing if the low temperature

water condition persists. See section 4D-2 for

information concerning further freeze protection for

the Endurance.

4.4.2 Anti-Freeze Boiler Additives

Power outage, interruption of gas supply, failure

of system components, activation of safety devices,

etc., may prevent a boiler from firing. Any time a

boiler is subjected to freezing conditions, and the

boiler is not able to fire, and/or the water is not

able to circulate, there is a risk of freezing in the

boiler or in the pipes in the system. When water

freezes, it expands. This can result in bursting of pipes

in the system, or damage to the boiler, which could

result in leaking or flooding conditions.

Do not use automotive anti-freeze. When the

Endurance is the combination space heating domestic

water model (EBP), a non-toxic anti-freeze, such as

propylene glycol, must be used. Maintaining a mixture

of minimum 65% water and maximum 35% properly

inhibited HVAC glycol, which contains an anti-

foamant, is the preferred method of freeze protection

for Endurance boilers. Percentage of glycol used in

the Endurance boiler must not exceed 35%.

Typically, this mixture will serve as burst protection

for temperatures down to approximately -35°F (-30°C).

IMPORTANT NOTES: Different glycol

products may provide varying degrees of protection.

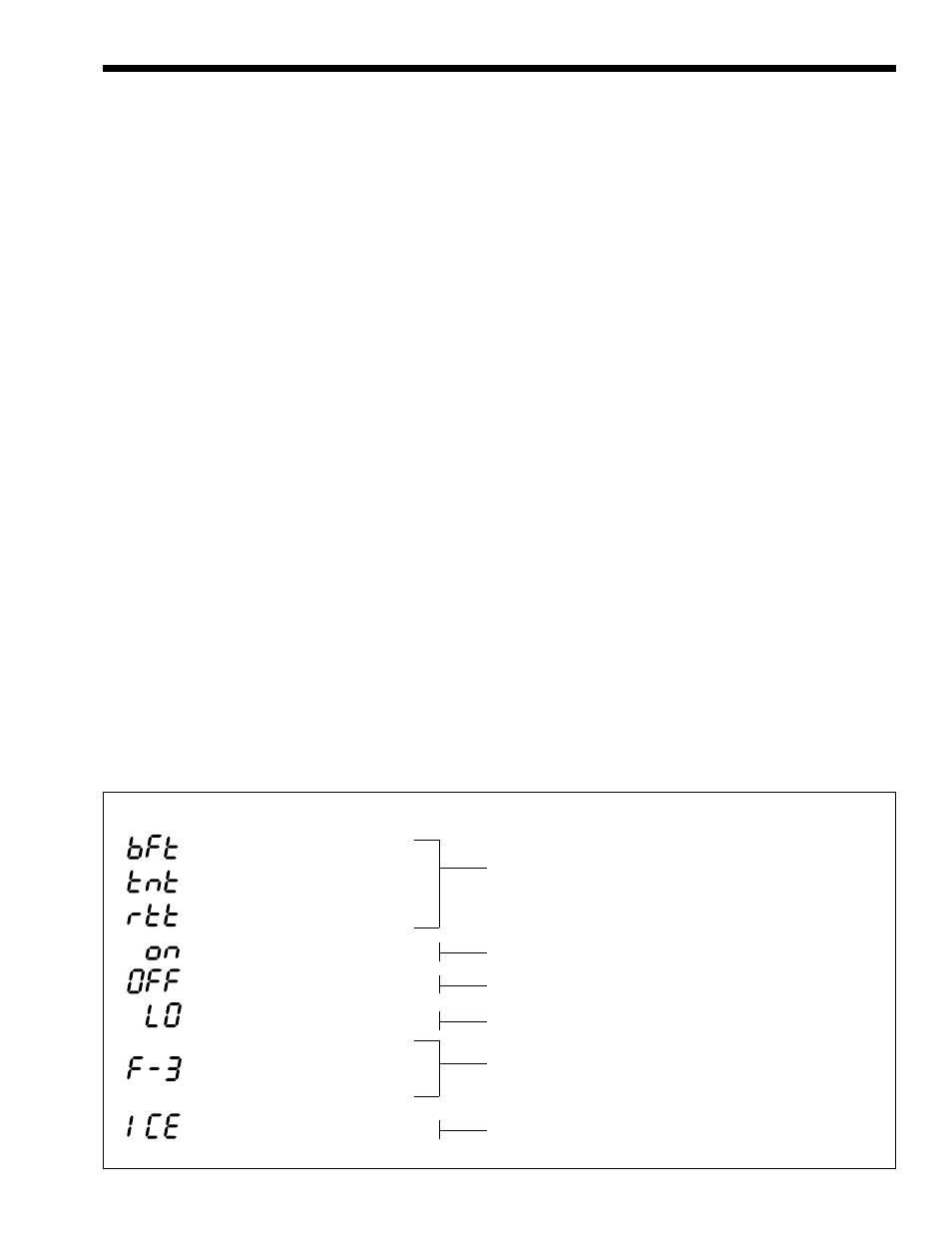

Identifies

Boiler Flow Temp (Supply)

Tank Temp

Return Temp (Boiler Inlet)

On

Off

Lock Out - Combustion Related

Fault Code (Three) There are 8

different Fault Codes defined.

Freeze Indicator

To read or change mode

During operation display will default to supply

temperature. Press temperatures button repetitively.

To sequence through three temperature indicators.

Boiler in standby mode: will operate on call for domestic

water or heat zone demand.

Boiler switched OFF. Press ON/OFF button for “ON”.

After three trials for ignition, will stand in lockout. Press

reset on top of panel to retry.

A fault code may be indicated on the display prior to pushing

the reset button or switching the on-off button or power

switch. Observe code, and note it, for servicing.

Sensor has detected return temperature below 39°F (4°C).

Figure 26. Typical Display Identification Codes.

Message