5 high gas consumption – LAARS EDN Series - Installation, Operation and Maintenance Instructions User Manual

Page 34

Page 34

LAARS HEATING SYSTEMS

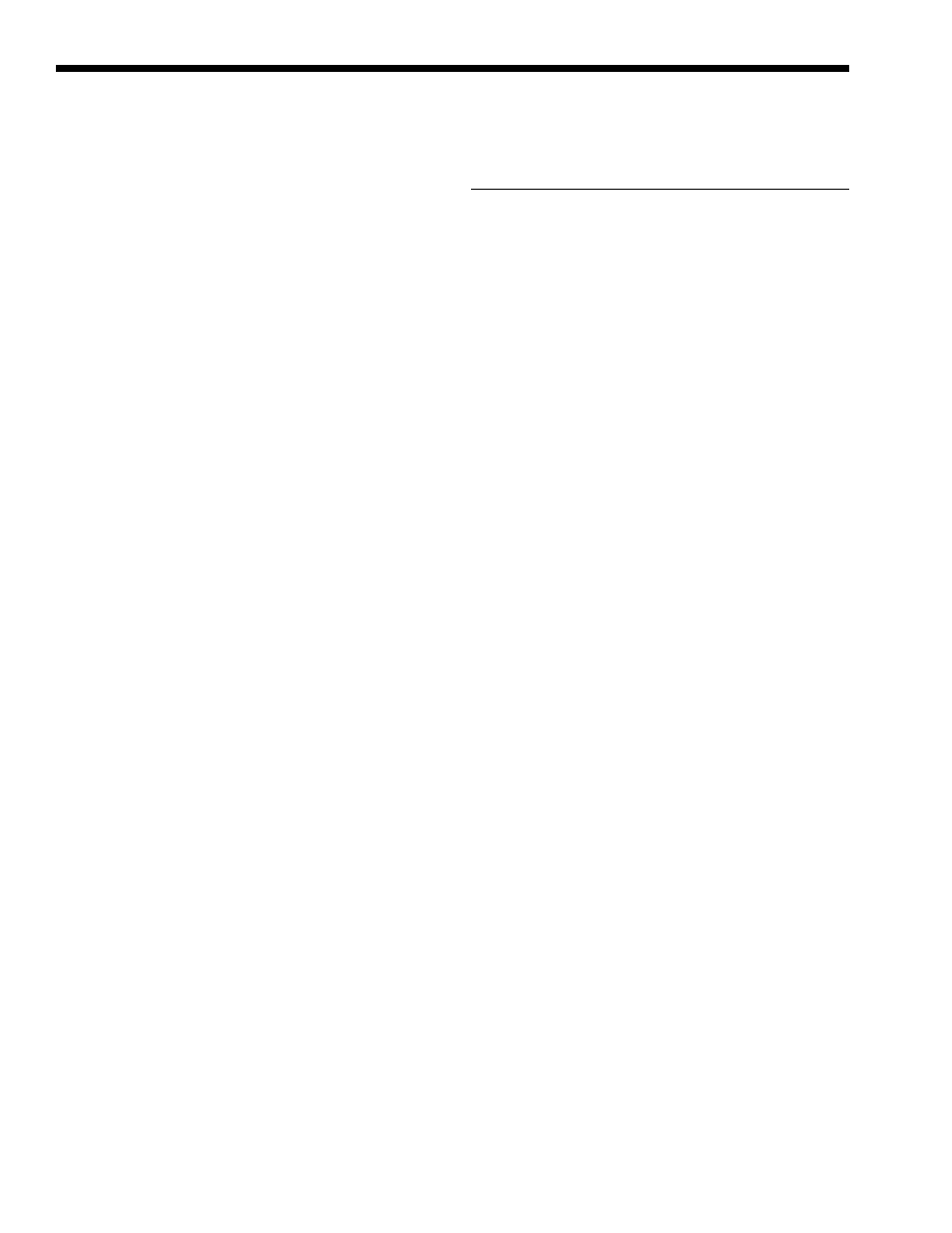

SECTION 11.

Parts Identification

Description

Part Number

1. PAN, COMBUSTION CHAMBER T0P

2400-502

2. PAN, COMBUSTION CHAMBER BOTTOM

2400-504

3. INSULATION, COIL COVER

2400-506

4. INSULATION, BOILER COIL

2400-508

5. COIL, BOILER, EBP/EDP/EDN 110 (ASSY.)

2400-510

6. COIL, BOILER, EBP/EDP/EDN 175 (ASSY.)

2400-512

7. GASKET, BURNER

2400-514

8. BURNER, EBP/EDP/EDN 110

(GASKETS INCLUDED)

2400-516

9. BURNER, EBP/EDP/EDN 175

(GASKETS INCLUDED)

2400-518

10. TRANSFER TANK

2400-520

11. BOILER DRAIN (BEHIND PANEL-EBP)

2400-522

12. BLOWER, COMBUSTION AIR

(GASKETS INCLUDED)

2400-524

13. IGNITOR/FLAME SENSOR

(GASKET INCLUDED)

2400-526

14. GASKET, IGNITOR/FLAME SENSOR

2400-528

15. COIN VENT

1-592

16. COMBUSTION AIR INLET,

ADJUSTABLE, KIT

2400-142

17. VALVE, ANTI CONDENSING,

REPAIR KIT

2400-538

18. GASKET, BLOWER

2400-540

19. WATER FLOW SWITCH

2400-542

20. BOILER CONTROL (BEHIND PANEL) (EBP)

2400-546

21. GAS VALVE, HONEYWELL,

NEG. REG. PRESSURE

2400-548

22. SAFETY LIMIT, 230 °F

2400-550

23. SENSOR, TANK ( EBP ONLY )

2400-552

24. SENSOR, BOILER FLOW

2400-554

25. SENSOR, BOILER RETURN

2400-556

26. THERMOSTATIC UNION EDP (NOT SHOWN)2400-030

27. GAS SHUTOFF VALVE

2400-560

28. PUMP, EBP/EDP 110

2400-592

29. PUMP, EBP/EDP 175

2400-386

30. GASKETS, PUMP FLANGE

2400-566

31. RESET SWITCH

2400-568

32. HEAT EXCHANGER, DOM. HOT WATER

2400-570

33. GASKETS, DHW HEAT EXCHANGER

2400-572

34. BUTTON, ON/OFF (PART OF 2400-546)

-

35. BUTTON, TEMP/MESSAGE

(PART OF 2400-546)

-

36. GAUGE, PRESSURE (NOT SHOWN)

2400-574

37. PRESSURE RELIEF VALVE

(30 PSIG, NOT SHOWN)

2400-112

38. BOILER CONTROL (BEHIND PANEL)

(EDP/EDN)

2400-558

39. PUMP, EDN 110

2400-388

40. PUMP, EDN 175

2400-388

41. THERMOSTATIC UNION EDN (NOT SHOWN)47-026

42. TRANSFORMER (NOT SHOWN)

2400-562

Failure of the mixing valve will allow cold water

to be mixed with the hot water from the DHW heat

exchanger during a DHW draw regardless of the

setting of the mixing valve or the temperature of the

water leaving the DHW heat exchanger. The failure

can be detected by observing the temperature of the

three pipes connected to the mixing valve. If the “mix”

temperature is luke warm or cool and the “hot”

temperature is hot and the “cold” temperature is cold

then the mixing valve is either faulty or incorrectly

adjusted and must be replaced or adjusted.

DHW heat exchanger scaling may occur in some

areas of the country where there are high

concentrations of minerals in the water. These

minerals may cause fouling of the DHW heat

exchanger over an extended period of time (lime build

up). Other minerals, which react more quickly in well

systems (mostly magnesium), cause slime on the

inside of the heat exchanger and prevent adequate heat

transfer. These minerals must be filtered out by a

special incoming water filter or by the addition of an

inhibitor to protect the coil and provide acceptable

water quality. Minerals may be removed when

necessary by flushing the coil with a cleaner such as

“Unlime®” or “Sizzle®”.

10.5 High Gas Consumption

Boilers operating with an improper air/fuel ratio

are very inefficient and consequently, have very high

gas consumption. Because efficiency is high when the

CO

2

is high, boilers operating with low CO

2

(especially LP boilers) consume more gas. Adjust the

CO

2

or O

2

for optimum efficiency. If no combustion

analyzing equipment (CO

2

or O

2

) is available then a

proper adjustment of the air/fuel ratio (CO

2

) can not

be accomplished. However, by briefly sniffing the flue

gases it is possible to determine if the CO

2

or O

2

is

within the proper range. There is no significant flue

gas odor when combustion is proper. A strong

piercing smell indicates poor combustion and

generally a lean mixture (low CO

2

). Check gas valve

calibration (offset adjustment) and adjust if indicated.

Do not attempt to correct combustion by reorificing

without an O

2

or CO

2

kit.