3 unpacking, 4 locating the cb boiler – LAARS 9600 CB - Installation, Operation and Maintenance Instructions User Manual

Page 4

Page 4

LAARS Heating Systems

1.3 Unpacking

The CB boiler is shipped in a single carton with

the following standard components on top of the unit.

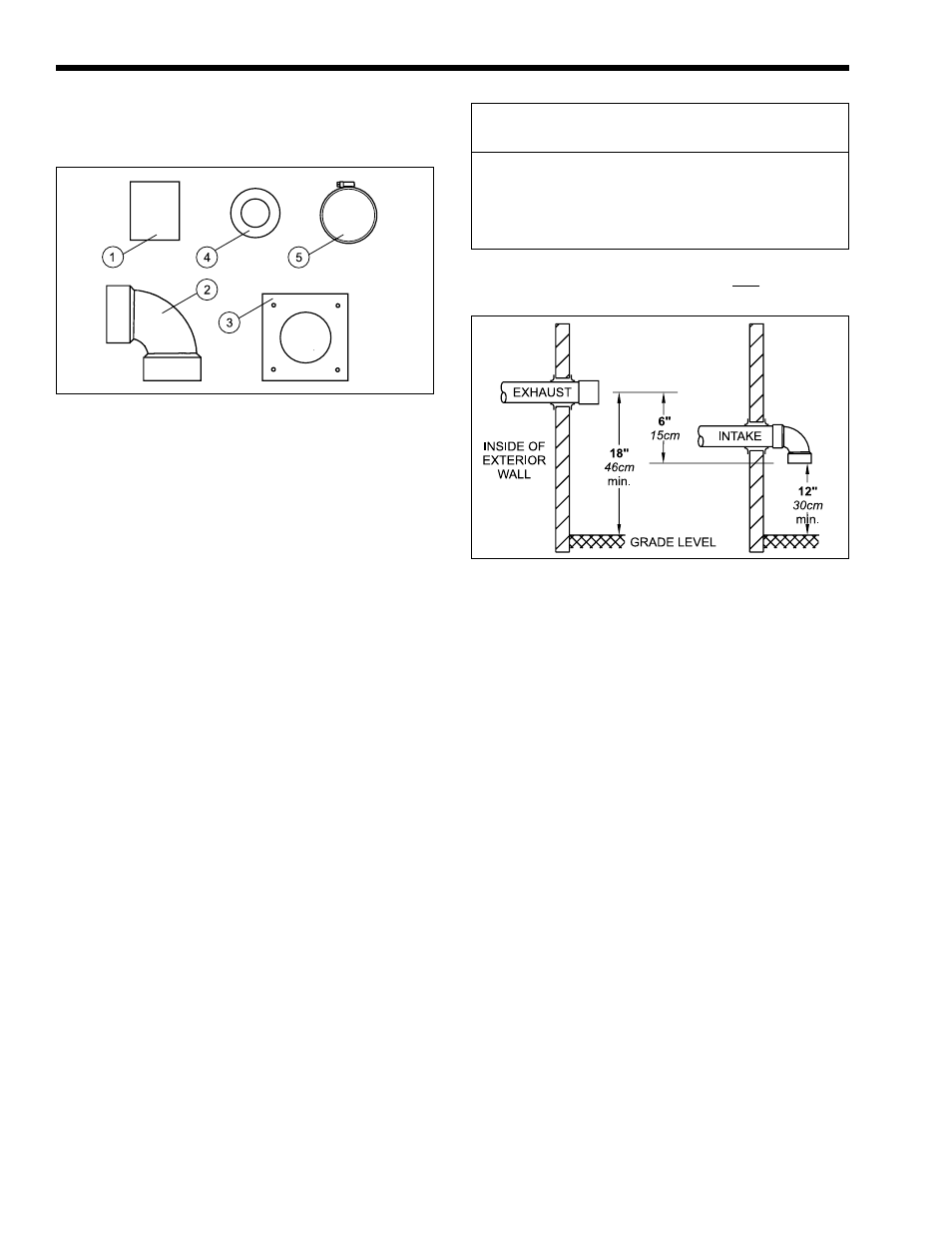

Figure 2. Contents of shipping package.

1. Exhaust terminal

4. Hubless coupling reducer

2. Intake terminal

5. Hubless couplings (2)

3. Backing plates (4)

a.

Remove all packing and tie-down materials.

b.

Check contents of the carton against items

shown above.

1.4 Locating the CB Boiler

The appliance should be located in an area

where leakage of any connections will not result in

damage to the area adjacent to the appliance or to

lower floors of the structure.

When such a location is not available, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance.

The unit is design certified by CSA for

installation on combustion flooring; in basements; in

closets, utility rooms or alcoves. It must not be

installed on carpeting.

The location for the unit should be chosen with

regard to the vent pipe lengths, external plumbing,

ventilation of operating components and accessibility

for service and cleaning.

The unit shall be installed such that the gas

ignition system components are protected from water

(dripping, spraying, rain, etc.) during operation and

service (circulator replacement, control replacement,

etc.).

If there is potential for snow accumulation in

your area, both vent terminals should be installed at an

appropriate level above grade.

The following dimensions and requirements

should be met when choosing the locations for the

unit:

a.

Minimum clearance from combustible materials

to meet CSA requirements.

b.

Recommended clearance for accessibility and

venting.

Clearance from

Service

Combustible Material

Access Clearance

Surface

U.S. / Canada

U.S.

Canada

Left Side

1"

2.5cm

6"

15 cm

24" 61cm

Right Side

1"

2.5cm

12" 30 cm

24" 61cm

Top

1"

2.5cm

14" 36 cm

24" 61cm

Back

1"

2.5cm

9"

23 cm

24" 61cm

Front

1"

2.5cm

24" 61 cm

24" 61cm

Vent

0"

Table 1. Clearances.

* NOTE: Roof terminations for air intake terminal must prevent entry of

rain water.

Figure 3. Suggested vent terminal installations.

1.5 Locating Unit for Correct Vent

Distance from Outside Wall or

Roof Termination

The forced draft combustion blower in the 9600

CB boiler has sufficient power to vent properly when

the following guidelines are followed.

Intake

Exhaust

Maximum run:

Maximum run:

3" pipe size

3" pipe size

55 equivalent feet

55 equivalent feet

4" pipe size

4" pipe size

105 equivalent feet

105 equivalent feet

85 ft. for Model 250

85 ft. for Model 250

Minimum run:

Minimum run:

11 equivalent feet

21½ equivalent feet

Intake Terminal is

Exhaust Terminal is

P/N 2400-102.

P/N 2400-104.

Equivalent feet is determined by adding 10

linear feet for each 90° elbow and 5 linear feet for

each 45° elbow to be installed to the actual linear feet

of pipe required.

Example: 8' of pipe, 2 x 45° elbows and a 90°

elbow.

Equivalent Feet: 8' + (2 x 5') + (1 x 10') = 28.

If a 4" pipe size is used to permit longer vent

runs the installer must supply 4" hubless couplings (2)

and 3 x 4 bushings (2) to adapt to the unit fittings. The

supplied vent terminals may be used with 3" diameter

pipes through the outside wall. Reducing couplings