LAARS 9600 CB - Installation, Operation and Maintenance Instructions User Manual

Page 3

9600 CB

Page 3

Automatically Fired Boilers, ANSI/ASME CSD-1.

In the Commonwealth of Massachusetts, this

appliance must be installed by a licensed plumber or

gas fitter.

1.2 Materials Installer Must Provide

SECTION 1.

Introduction and Unpacking

1.1 General Instructions

It is important for you to take a few minutes to

review this Installation and Operating Instructions

manual before you begin installation. This will make

installing and operating the unit easier and faster.

Direct vent-sealed combustion:

The 9600 CB boiler does not and should not take

combustion air from inside the building. All of the air

is drawn in from outdoors through a 3-inch diameter

plastic pipe. 3" PVC, ABS or CPVC pipe is used for

air intake and exhaust venting. (PVC, ABS not

permitted for CB-M2-250 exhaust).

No chimney....flue....or draft inducer required.

Because this is a sealed combustion, forced draft unit,

it does not require, and must not be connected to a

chimney, existing venting system, or draft inducer.

Caution

Connection of this vent to a chimney, existing venting

system, or draft inducer will result in poor and possibly

dangerous operation.

The supplied vent terminations are designed to

be installed through the nearest outside wall.

The CB boiler is protected against over

pressurization. A 50 PSI pressure relief valve is fitted

to all units and a 125 PSI valve is optional. It is

installed in the dedicated fitting on the back of the

boiler.

IMPORTANT: The inlet gas pressure to the appliance

must not exceed 13" WC.

A high quality circulator is built into the CB

boiler and will provide sufficient head to circulate

water to the supply and return headers. An external

circulator is required to circulate water to and from

baseboard or fan coil units (secondary loop).

All installations must be made in accordance

with the 1). American National Standard Z223.1-

Latest Edition “National Fuel Gas Code” or 2). CSA

B149.1 "Installation Codes for Gas Burning

Appliances and Equipment" and with the requirement

of the local utility or other authorities having

jurisdiction. Such applicable requirements take

precedence over the general instructions contained

herein.

All electrical wiring is to be done in accordance

with the local codes, or in the absence of local codes,

with: 1). The National Electrical Code ANSI/NFPA

No. 70-latest Edition, or 2). CSA STD. C22.1

"Canadian Electrical Code - Part 1". This appliance

must be electrically grounded in accordance with

these codes. Where required by the authority having

jurisdiction, the installation must conform to the

Standard for Controls and Safety Devices for

a.

Total combined feet allowed for intake and

exhaust vent pipe per instructions. The following

are acceptable materials for intake and exhaust

vents:

b.

Electrical connection to a 120VAC/15Amp

service.

c.

Gas connection that will provide 250 cubic feet/

hour at 4 to 13 inch water gauge pressure.

d.

Condensate drainage: a floor drain is preferred, a

condensate pump can be used if required.

e.

Miscellaneous copper fittings and bronze valves

will be required to complete the piping system.

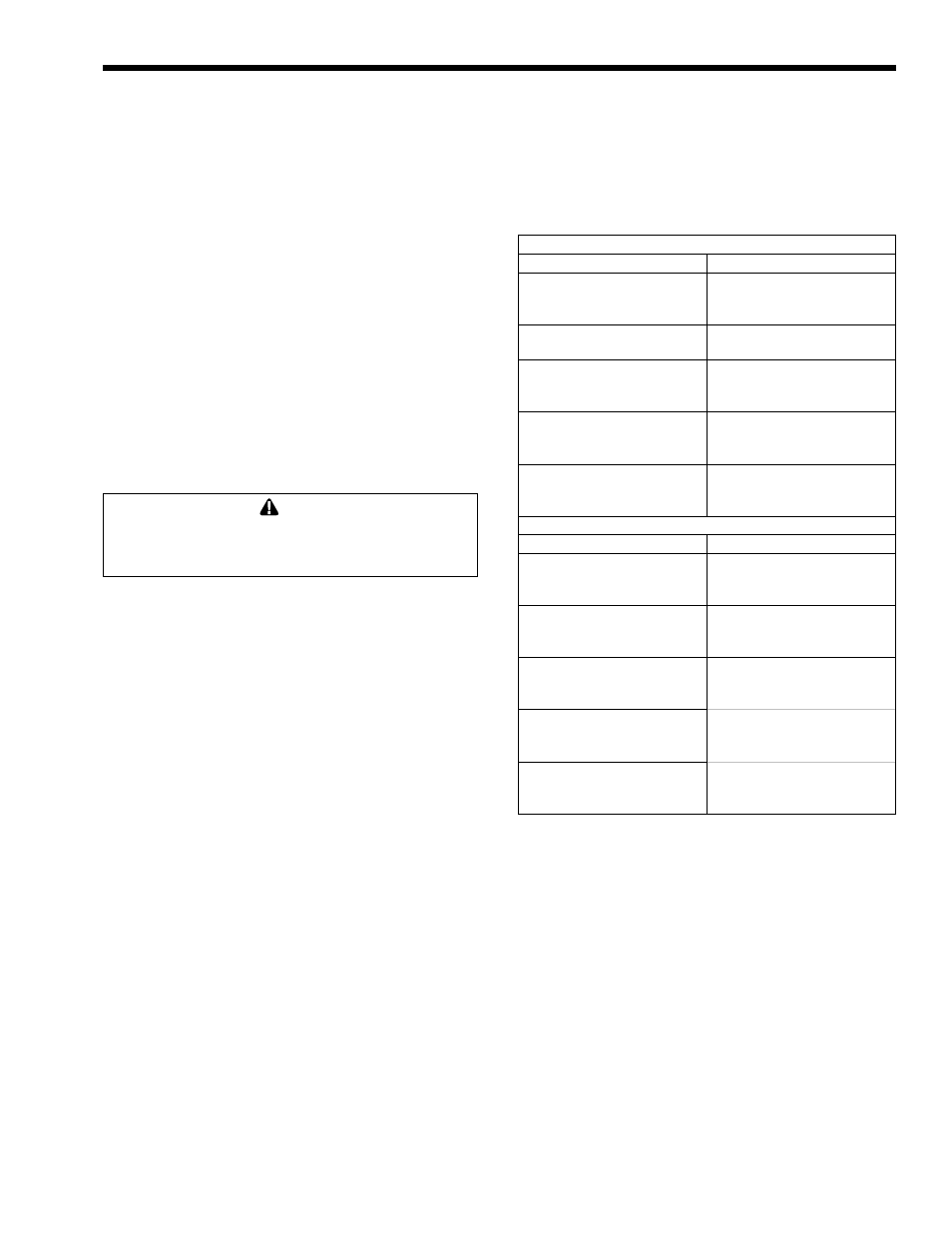

M ode ls 150-200

M ode l 250

3-inch or 4-inch PVC

schedule 40 pipe per ASTM

D-1785 std.

3-inch or 4-inch PVC

schedule 40 pipe per ASTM

D-1785 std.

3-inch or 4-inch PVC DWV

pipe per ASTM D-2665 std.

3-inch or 4-inch PVC DWV

pipe per ASTM D-2665 std.

3-inch or 4-inch ABS-DWV

pipe per ASTM D-2661 std.

or ASTM F-628 std.

3-inch or 4-inch ABS-DWV

pipe per ASTM D-2661 std.

or ASTM F-628 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch AL29-4C

stainless steel complying

with UL std. 1738.

3-inch or 4-inch AL29-4C

stainless steel complying

with UL std. 1738.

M ode ls 150-200

M ode l 250

3-inch or 4-inch PVC

schedule 40 pipe per ASTM

D-1785 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch PVC DWV

pipe per ASTM D-2665 std.

3-inch or 4-inch AL29-4C

stainless steel complying

with UL std. 1738.

3-inch or 4-inch ABS-DWV

pipe per ASTM D-2661 std.

or ASTM F-628 std.

3-inch or 4-inch CPVC

schedule 40 or 80 pipe per

ASTM F441 std.

3-inch or 4-inch AL29-4C

stainless steel complying

with UL std. 1738.

Acce ptable Exhaust Ve nt Pipe M ate rial

Acceptable Intake Pipe Material