LAARS EBP 175 MBTU/h - Installation, Operation and Maintenance Instructions User Manual

Page 5

Endurance

Page 5

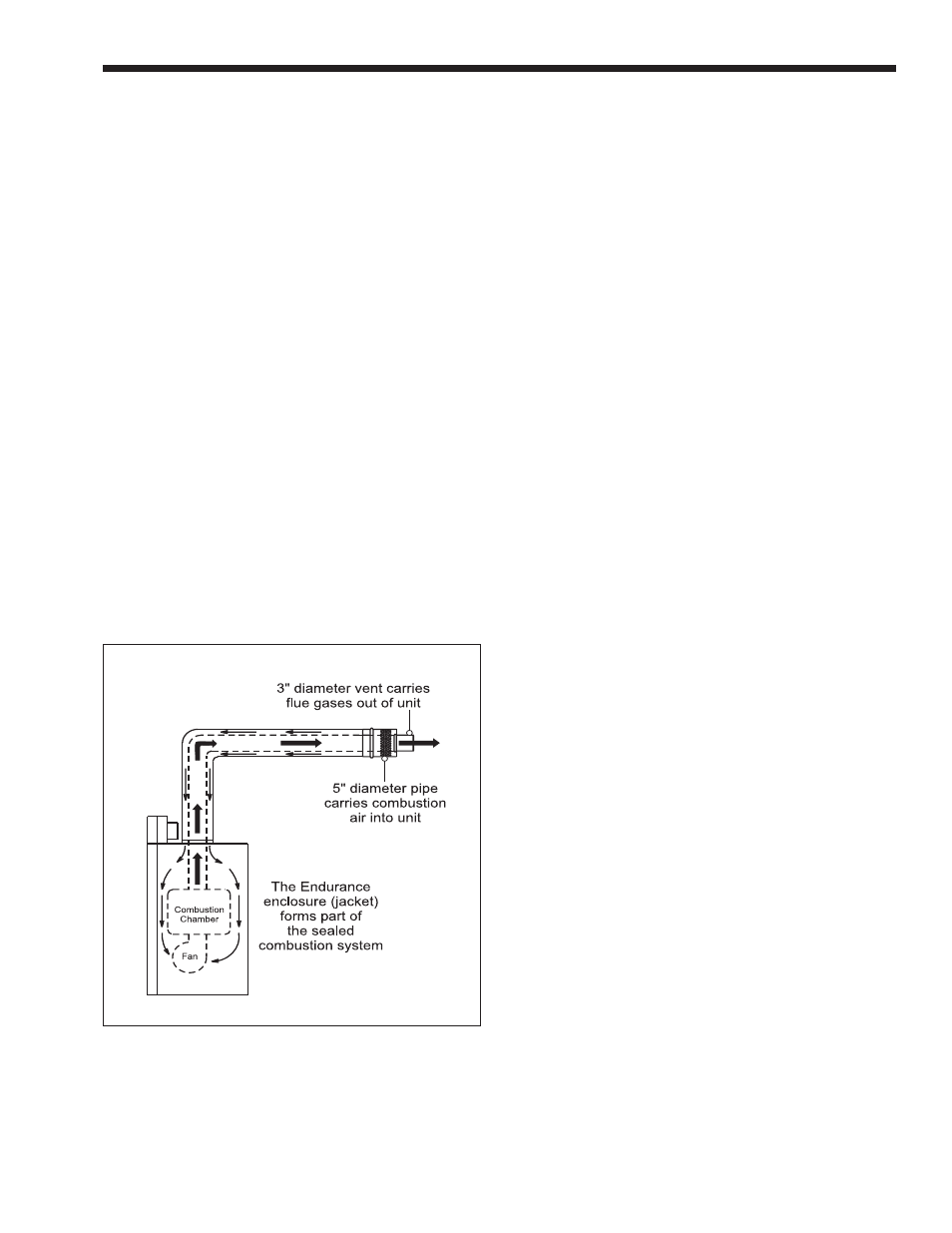

2.1 Concentric Direct Vent

2.1.1 Concentric Vent Description

Endurance concentric direct vent is a sealed-

combustion system. It can be used for vent systems

with a maximum of 15 linear feet (4.6m) and three

elbows. All of the air is drawn in from the outside

through a 5" stainless steel outer pipe. Flue gases

are vented through a 3" stainless steel pipe that is

positioned inside the 5" intake pipe. Hot flue gases

are surrounded by the intake flow of cooler outdoor

air (

see Figure 4

). Laars offers two concentric vent

kits, described in section 2.1.2. Laars concentric vents

may be installed through, and be in contact with,

combustible materials.

2.1.2 Laars Concentric Vent Kits

The Endurance is certified with a maximum of

15 linear feet (4.6m) of concentric piping and three

sets of elbows. There are two concentric vent kits

offered by Laars. Both kits, and all Laars Endurance

vent material meet the requirements of U.L. Standard

1738 and U.L.C. Standard 636. The horizontal vent kit

is part number

2400-009

. The vertical vent kit is part

number

2400-011

. See

Figures 5 and 6

, which show

the components included with the kits and venting

configurations. Installation instructions are included

with the kits. Rules for concentric venting, vent

material and vent terminal placement are discussed in

Figure 4. Combustion Air and Flue Gas Paths.

2.1.3 Horizontal Concentric Vent Location

The centerline of the vent opening must be at

least 16-1/2" (42cm) above grade, outside. Should it

be impossible to locate the opening centerline 16-1/2"

(42cm) above grade, use optional concentric vent

terminal extension (part number

2400-428

), shown in

Figure 7

.

In the U.S., vent terminals must be at least 3 feet

(0.9m) above any forced air inlet located within 10

feet (3.0m). In Canada, vent terminals must be at least

6 feet (1.8m) from any forced air inlet.

In the U.S., a direct vent terminal must be at

least 12" (30cm) from any window or door that may

be opened, or any other nonmechanical opening.

For an Endurance that is not direct vented (vented as

Category IV), the vent terminal must be at least 4 feet

(1.2m) below or to the side of, and 12" (30cm) above

any such opening.

In Canada, a direct vent or non-direct vent

terminal must be at least 36" (91cm) from any window

or door that may be opened, or any other non-

mechanical opening.

The vent opening should be well away from

shrubbery or other obstructions that would prevent free

air flow to and from the vent terminal.

If the vent terminal location chosen is less than

18" (46cm) below an overhang, the 3" vent pipe

must extend to the outside edge of the overhang,

to prevent the accumulation of flue gas (

see Figure

9

). Accumulating flue gas can contaminate the

combustion air, causing nuisance lockouts of the

ignition system. In addition, accumulation of flue

gases can settle on, and damage the structure’s

surfaces.

Vent terminals must not terminate in a location

where condensate or vapor may be a nuisance, hazard,

or could be a detriment to other equipment.

See Figure

8

for more detail concerning vent terminal placement

in the U.S. and Canada.

Do not locate the vent terminal where blockage

by snow is a possibility, or where flue products

could strike against building materials and cause

degradation.

When multiple Endurance units are used,

the concentric vent terminals may be side-by-side,

provided that they are at least 18" (46cm) apart,

centerline to centerline (

see Figure 10

).

A horizontal vent system must pitch downward,

toward the terminal and away from the Endurance,

as shown in

Figure 11

. It must pitch at least 1/4"

per foot (21mm per meter). Be sure to take this

into consideration when choosing the vent terminal

location.

The vertical vent terminal must be placed such

that the bottom of the vent cap is at least 2-feet (0.6m)

above any structure (such as the peak of a roof or

adjacent wall) within 10 feet (3.0m), and must be at

the rest of

Section 2

of this manual.

For additional length, and/or fittings, to extend

the kits to maximum 15 linear feet (4.6m) and three

elbows, individual components are available. These

components are shown in

Figure 7

.