LAARS EBP 175 MBTU/h - Installation, Operation and Maintenance Instructions User Manual

Page 22

Page 22

LAARS Heating Systems

valve manufacturer’s instructions. Connect

circulator (120 volt, 5 amp maximum) between

the blue wire and the white wire (neutral) (see

Figure 26

).

4. Multi zone/Multi-relay-circulator Installations:

Multiple circulators must not exceed 5 amps total

when connected to blue wire (see

Figure 28

).

NOTE: On zone valve systems such as Taco,

Automag and others which do not have isolated (dry)

contact end switches, a single pole isolating relay

must be utilized (see

Figure 27

).

SECTION 6.

Using the Boiler Control

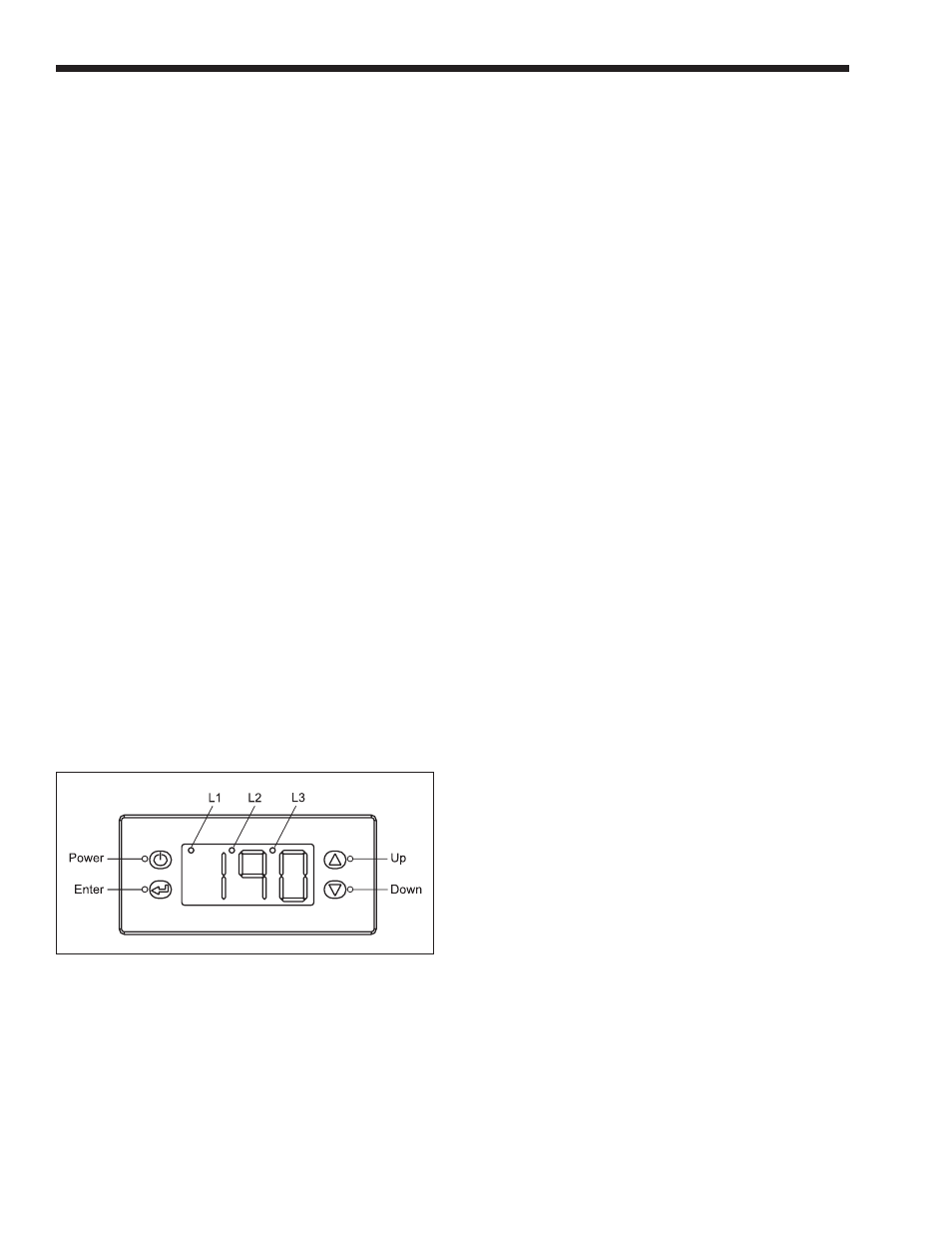

6.1 Front Panel Display

Figure 30

shows the front panel display of the

boiler control. The Endurance boiler control has

four buttons, which are used to access viewing and

programming menus. The LED’s at the top of the

control show the sequence of events, from left to right:

Pump Status, TH Status (boiler attempting to run) and

Gas Valve Status.

There are three LEDs that illuminate at the top

of the controller, shown as L1, L2 and L3 in

Figure

30

. These light from left to right, in order of the events

that happen when the Endurance receives a call for

heat.

L1 (LED on top left of display) lights when the

pump is energized.

L2 (LED in the middle top of display) lights

when the boiler is attempting to light burner.

L3 (LED on the top right of display) lights when

For instance, if the Burner Off Point is chosen as

190°F (88°C), with a fixed 10°F (6°C) differential, the

control will strive to keep the supply temperature at

180°F (82°C).

In this example, when the Endurance gets the

initial call for heat, it will start at low fire, and begin its

heat-up. The control monitors how quickly the supply

temperature is increasing, and bases its modulating

rate (output Btu/hr) on that rate of change. The output

of the unit will reduce as the water temperature

approaches 180°F (80°C). It will attempt to remain at

180°F (80°C) for the entire call for heat. If the system

requires less heat than the lowest modulating rate,

the outlet water temperature will rise past the Burner

Control Point of 180°F (82°C), and will eventually

reach the Burner Off Point of 190°F (88°C) and shut

off.

The control also has a Burner On Point that is

calculated by subtracting the Burner On Differential

from the Burner Control Point. The Burner On

Differential is fixed at 13°F (7°C) on the to ensure that

the tank will always be charged properly for domestic

water calls for heat. In the example here, with a 13°F

(7°C) Burner On Differential, that would mean a

Burner On Point of 167°F (75°C). During a call for

heat, if the Endurance reaches its Burner Off Point,

the control will allow the supply temperature to drop

to the Burner On Point of 167°F (75°C) before it fires

again.

Figure 31

shows a graph of this example.

6.3 View Menu

The boiler control allows the user to view the

temperatures that are being read by the sensors.

The default display for the boiler control is the

supply temperature (defined below). To scroll through

and view the other readings, press the up or down

button.

Figures 32 and 33

show the locations of the

temperature sensors. Temperatures available in the

view menu are:

a. Supply Temperature (shown as the default

display) — The temperature of the water leaving

the boiler heat exchanger.

b. Return Temperature (shown as “rtn”) – The

temperature of the water entering the boiler heat

exchanger. (Note that this is not system return

temperature. It is the inlet to the heat exchanger,

which is system return mixed with boiler outlet

water.)

c. Tank Temperature. The temperature of the water

in the transfer tank.

d. Heat Exchanger Delta T (shown as “dt”) – The

temperature difference between the inlet and

outlet of the boiler heat exchanger.

5. Outdoor Air Temperature (shown as “Oat” when

used) – The temperature at the outdoor air sensor.

Figure 30. Boiler Control.

the gas valve is energized.

6.2 Control Logic

The user sets the Burner Control Point by

programming the Burner Off Point. The boiler

control modulates the burner to keep the boiler outlet

temperature at the boiler control point.

The Burner Off Point minus the Off Point

Differential is the Burner Control Point. The Off Point

Differential is fixed at 10°F (6°C).