360dvs series direct vent fireplaces, How to use the vent graph, Rear wall application – Vermont Casting 360DVSL User Manual

Page 15: Rear wall installation

15

360DVS Series Direct Vent Fireplaces

10006326

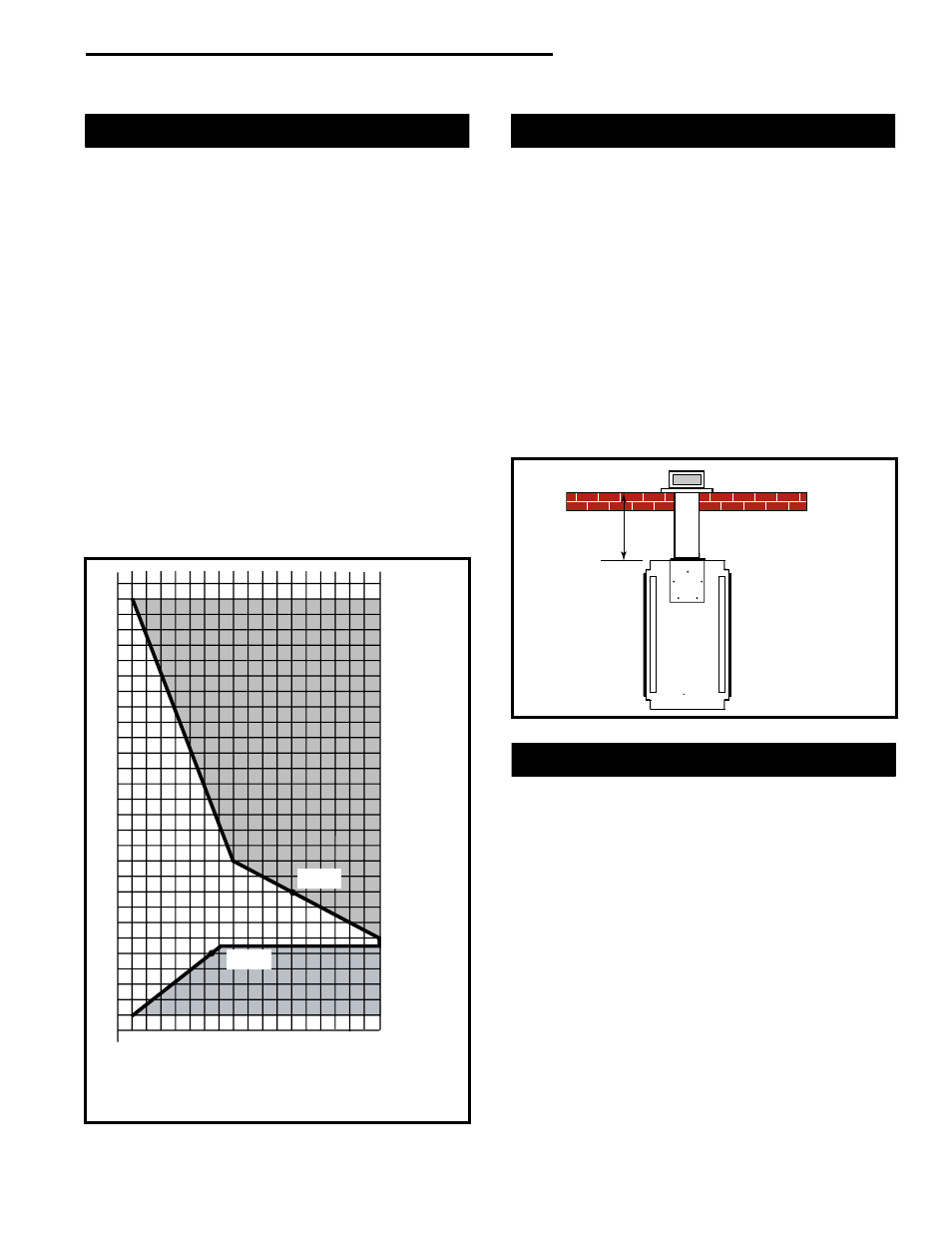

How to Use the Vent Graph

The vent chart should be read in conjunction with the

following vent installation instructions to determine the

relationship of the vertical and horizontal dimensions of

the vent system.

1. Determine the height of the center of the horizontal

vent pipe exiting through the outer wall. Using this

dimension on the Sidewall Vent Graph bellow,

locate the point intersecting with slanted graph line.

2. From the point of this intersection, draw a vertical

line to the bottom of the graph.

3. Select the indicated dimension, and position the

fireplace in accordance with same.

Example A:

If vertical dimension from floor of the fireplace is 11’

(3.4m), horizontal run to the face of outer wall must

not exceed 14’ (4.3m).

Example B:

If vertical dimension from floor of the unit is

7’ (2.14m), horizontal run to the face of outer wall

must not exceed 8

¹⁄₂

’ (2.6m).

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

eg: A

eg: B

V

ertical dimension from floor of the unit

to center of the horizontal vent pipe

DV Graph

Horizontal dimension from outside of the wall

to the center of the fireplace vent flange

Sidewall vent graph showing the relationship between vertical and

horizontal dimensions for a Direct Vent flue system.

Fig. 16 Sidewall vent graph.

Rear Wall Application

When installed as a rear vent unit this appliance may

be vented directly to a termination located on the rear

wall behind the appliance.

•

Specific rear vent starter kits must be used in these

applica

tions (see ‘venting components’). The appli-

ance has been approved for installation flat against a

rear wall. (Fig. 17)

•

Maximum horizontal distance between the rear of

the appliance and the outside face of the rear wall is

20” (508mm). (Fig. 17)

•

Minimum clearances between any combustible

material and the vent pipe sections are:

Top ............................................... 2” (51mm)

Sides ............................................ 1” (25mm)

Bottom ......................................... 1” (25mm)

Max. 20”

(508mm)

FP1434

Fig. 17 Rear vent application.

Rear Wall Installation

Step 1

Locate and cut vent opening in the rear wall.

Combustible walls: Cut a rectangular hole measuring

10

³⁄₈

” H x 9

³⁄₈

” W (265 x 240mm) through the exterior

wall and frame. Frame in the opening per Figure 18.

Noncombustible walls: Cut a round hole measuring

7

¹⁄₂

” (190mm) diameter through the exterior wall and

frame. (Fig. 18)

STEP 2

For combustible walls: Measure wall thickness and cut

zero clearance sleeve parts to proper length.

Max. length is 12” (305mm). Assemble sleeve

to its maximum opening of 10

³⁄₈

” x 9

³⁄₈

” (265 x

240mm), and attach to firestop with #8 sheetmetal

screws (supplied). Install firestop assembly. (Fig. 19)

NOTE: Zero clearance sleeve is required only for

combustible walls.