Carrier 38AKS028-044 User Manual

Page 21

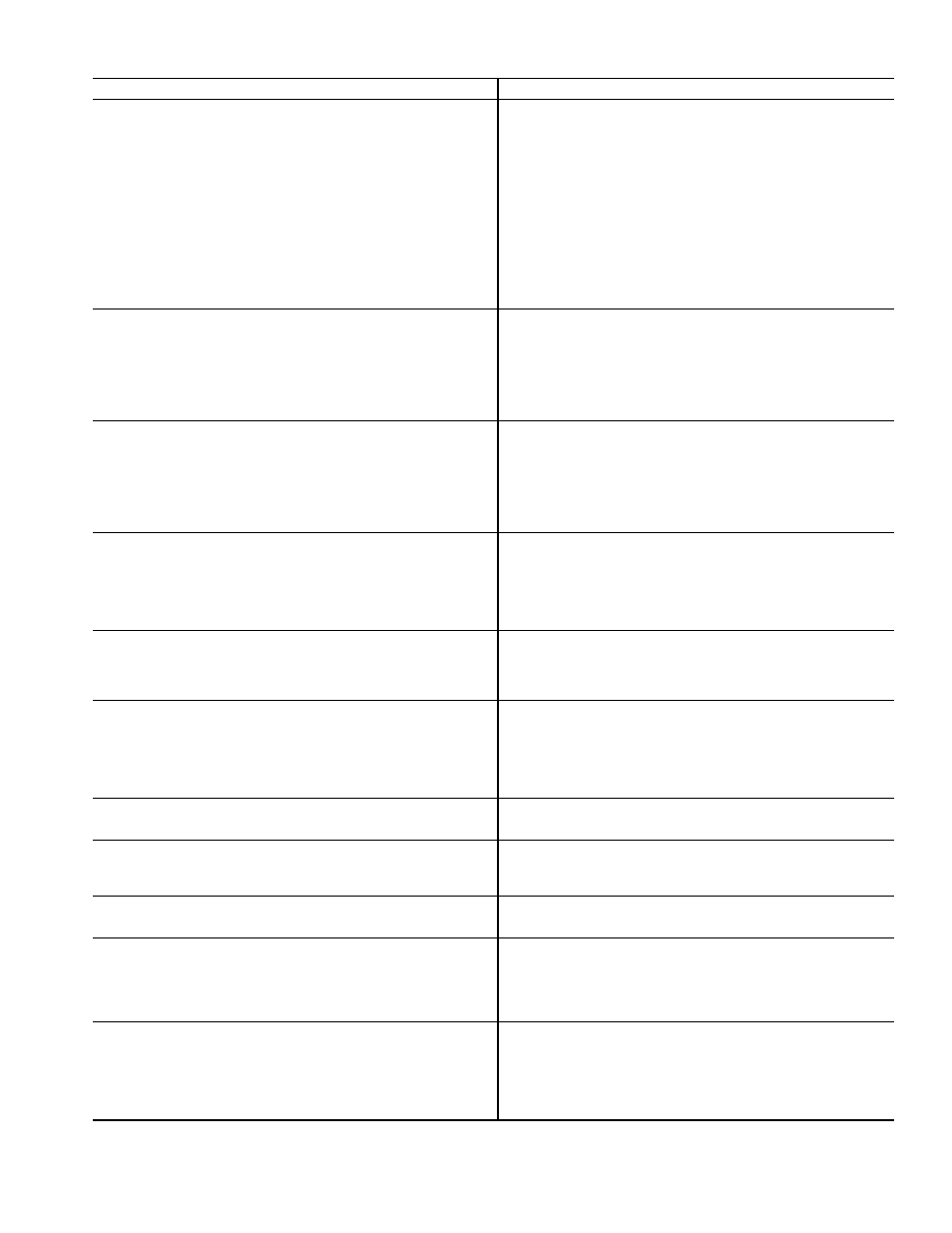

TROUBLESHOOTING

SYMPTOM AND PROBABLE CAUSE

PROBABLE REMEDY

COMPRESSOR DOES NOT RUN

1. Control circuit breaker tripped

1. Reset control circuit breaker

2. Power line open

2. Reset circuit breaker

3. Oil pressure switch tripped

3. Reset oil pressure switch at unit

4. Safety device tripped

4. Reset control circuit with thermostat

5. Contactor stuck open

5. Replace contactor

6. Loose terminal connection

6. Check connections

7. Improperly wired controls

7. Check and rewire

8. Seized compressor

8. Check motor winding for open or short.

Replace compressor, if necessary

9. Low line voltage

9. Check line voltage — determine location of

voltage drop and remedy deficiency

10. Compressor motor defective

10. Check motor winding for open or short.

Replace compressor, if necessary

COMPRESSOR STOPS ON LOW-PRESSURE

CONTROL

1. Compressor suction shutoff valve partially closed

1. Open valve

2. Low refrigerant charge

2. Add refrigerant

3. Liquid line solenoid valve(s) fails to open

3. Check liquid line solenoid valve for proper

operation. Replace if necessary

4. Liquid line shutoff valve closed

4. Open valve

COMPRESSOR STOPS ON HIGH-PRESSURE

CONTROL

1. Compressor discharge valve partially closed

1. Open valve or replace if defective

2. Air in system

2. Purge and evacuate system

3. Condenser fan(s) not operating

3. Check motor wiring and repair or replace if

defective

4. System is overcharged.

4. Reclaim charge as needed

UNIT OPERATES TOO LONG OR

CONTINUOUSLY

1. Low refrigerant charge

1. Add refrigerant

2. Control contacts fused

2. Replace control

3. Air in system

3. Purge and evacuate system

4. Partially plugged expansion valve or filter drier

4. Clean or replace

SYSTEM IS NOISY

1. Piping vibration

1. Support piping as required

2. Compressor noisy

2. Check valve plates for valve noise. Replace

compressor if bearings are worn

COMPRESSOR LOSES OIL

1. Leak in system

1. Repair leak

2. Crankcase heaters not energized during

2. Check wiring and relays. Check heater and

shutdown

replace if defective

3. Improper interconnecting piping design

3. Check piping for oil return. Replace if

necessary

FROSTED SUCTION LINE

1. Expansion valve admitting excess refrigerant

1. Adjust expansion valve

HOT LIQUID LINE

1. Shortage of refrigerant due to leak.

1. Repair leak and recharge

2. Expansion valve opens too wide

2. Adjust expansion valve

FROSTED LIQUID LINE

1. Restricted filter drier

1. Remove restriction or replace

COMPRESSOR WILL NOT UNLOAD

1. Defective unloader

1. Replace

2. Defective capacity control solenoid valve

2. Replace valve

3. Miswired liquid line solenoid

3. Rewire correctly

4. Weak, broken, or wrong valve body spring

4. Replace spring

COMPRESSOR WILL NOT LOAD

1. Miswired capacity control liquid solenoid

1. Rewire correctly

2. Defective capacity control solenoid valve

2. Replace valve

3. Plugged strainer (high side)

3. Clean or replace strainer

4. Stuck or damaged unloader piston or piston

4. Clean or replace the necessary parts

ring(s)

21