Oil pressure safety switch (ops), Compressor protection, High-pressure switch – Carrier 38AKS028-044 User Manual

Page 20: Low-pressure switch, Winter start control, Head pressure control

Oil Pressure Safety Switch (OPS) —

The OPS in

the control circuit stops the compressor and unit, if proper

oil pressure differential is not established at start-up or main-

tained during operation. If OPS stops the unit, determine the

cause and correct before restarting unit. Failure to do so will

constitute abuse. Equipment failure due to abuse may void

the warranty.

Compressor Protection

CIRCUIT BREAKER — Calibrated trip manual reset, am-

bient compensated, magnetic breaker protects against motor

overload and locked rotor conditions.

CONTROL MODULE TIMER — This control protects com-

pressor against short cycling. See Sequence of Operation on

page 17.

CRANKCASE HEATER — This minimizes absorption of

liquid refrigerant by oil in crankcase during brief or ex-

tended shutdown periods.

IMPORTANT: Never open any switch or disconnect

that deenergizes the crankcase heater unless unit is be-

ing serviced or is to be shut down for a prolonged pe-

riod. After a prolonged shutdown on a service job, en-

ergize the crankcase heater for 24 hours before starting

the compressor.

High-Pressure Switch —

This switch has fixed, non-

adjustable settings. Switch is mounted on the compressor (See

Table 4).

Low-Pressure Switch —

This switch has fixed, non-

adjustable settings. Switch is mounted on the compressor.

(See Table 4.)

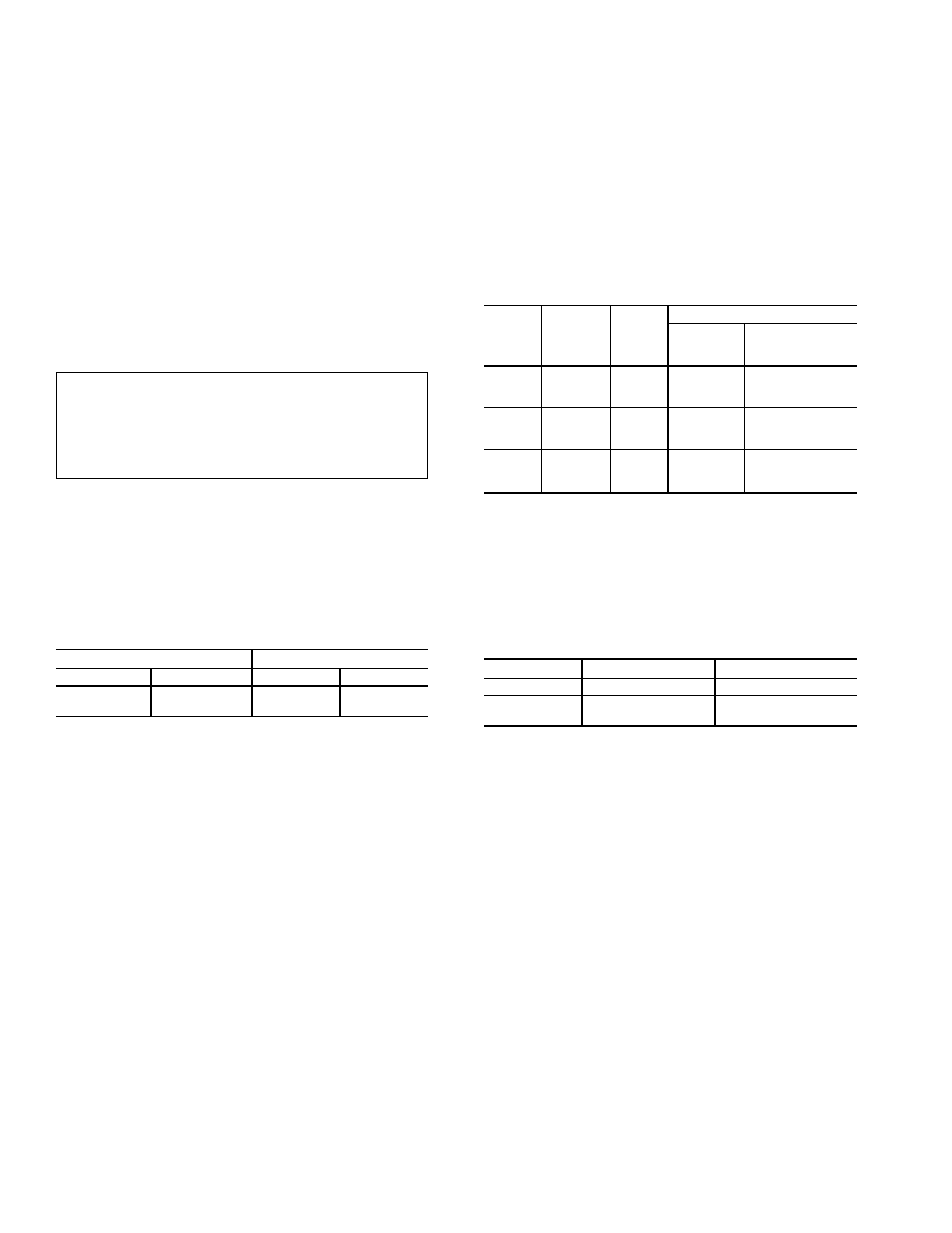

Table 4 — Pressure Switch Settings, psig (kPa)

HIGH PRESSURE

LOW PRESSURE

Cutout

Cut-in

Cutout

Cut-in

426 ± 7

(2937 ± 48)

320 ± 20

(2206 ± 138)

27 ± 3

(186 ± 21)

44 ± 5

(303 ± 34)

Winter Start Control —

Bypass relay timer bypasses

low-pressure switch for 2 minutes on unit start-up.

Head Pressure Control —

Control maintains ad-

equate discharge pressure under low ambient temperature con-

ditions. See Table 5.

FAN CYCLING — These 38AKS units have standard pro-

vision for fully automatic intermediate-season head pressure

control through condenser fan cycling. Fan no. 2 is cycled

by a fan cycling pressure switch (FCPS) which responds to

variation in discharge pressure. The pressure sensor is lo-

cated in the liquid line of the refrigerant circuit. Fan no. 3

cycling is controlled by outdoor-air temperature through an

air temperature switch (ATS) (38AKS044 units only).

Table 5 — Minimum Outdoor-Air

Operating Temperature

UNIT

38AKS

COMPR

CAP. (%)

COND

TEMP,

F (C)

MIN OUTDOOR TEMP, F (C)

Standard

Unit

Low Ambient

Control

(Motormaster

ா

)

028

100

90 (32)

31 (–1)

–20 (–29)

67

80 (27)

35 (2)

–20 (–29)

33

70 (21)

43 (6)

–20 (–29)

034

100

90 (32)

30 (–1)

–20 (–29)

67

80 (27)

34 (1)

–20 (–29)

33

70 (21)

42 (6)

–20 (–29)

044

100

90 (32)

25 (–4)

–20 (–29)

67

80 (27)

30 (–1)

–20 (–29)

33

70 (21)

35 (2)

–20 (–29)

The ATS is located in the lower divider panel between the

compressor compartment and condenser section. Through a

hole in the panel, the sensing element is exposed to air en-

tering the no. 1 fan compartment. Fan no. 1 is noncycling.

Table 6 shows the operating settings of the FCPS and the

ATS.

Table 6 — Fan Cycling Controls

CONTROL BY

SWITCH OPENS

SWITCH CLOSES

Temp, F (C)

70 ± 3 (21 ± 1.7)

80 ± 3 (27 ± 1.7)

Pressure,

psig (kPa)

160 ± 10 (1103 ± 69)

260 ± 15 (1793 ± 103)

NOTE: See Fig. 6 and 7 for fan arrangement.

20