Electrical and operational checks, Installation of remote control center – Chromalox FXTH PN401 User Manual

Page 6

ELECTRICAL AND OPERATIONAL CHECKS

A. Having circuit breaker and power switch in “off” position, make

sure proper voltage supplied matches voltage of control panel and

elements.

B. Adjust controlling thermostat in terminal housing to a 50°F read-

ing. Increase setting until thermostat switch just “clicks”. This

setting is to be used for initial heater checkout.

C. Turn circuit breaker to “on” and note green power light coming

on. Turn on power switch and note first amber light will come on,

and then subsequent amber light(s) as explained in Section.

D. Observe control panel as heater goes through several heating

cycles. A cycle is determined when all amber lights are off. Cycle

interval can vary widely depending on amount of oil in tank.

However, the thermostat has been set to keep the cycle time to a

minimum.

E. Turn off circuit breaker and power switch, then re-set thermostat

to desired setting for normal operation. The thermostat contains a

factory adjusted stop which prevents settings above 150°F.

F. If low temperature alarm feature is provided, set this control 10°

to 15°F below the control thermostat setting.

G. Installation of terminal housing lid and gasket (with proper gasket

sealant) completes the check-out procedure.

H. If any difficulties are encountered during the installation and

check-out, call your local Chromalox Representative or

Chromalox Product Service.

INSTALLATION OF REMOTE CONTROL CENTER

CAUTION: Hazard of electric shock. Any installation involving

electric must be grounded to earth to eliminate shock hazard.

1. A safe maximum temperature limit on control cabinet compo-

nents is 125°F. Choose a mounting location not in direct sunlight

or exposed to any other source of excessive heat. If the panel must

be mounted in direct sun, a sun shield must be employed.

2. Install proper control and power wiring to control center as per

Figure J. Power lines are to be sized for the particular heater load.

Double check to insure proper grounding procedures have been

followed for heaters and control panel.

3. Available inside control panel are connections A and A1 which

provide for an over-temperature alarm; such as, horn, bell, etc., to

be mounted remotely as required. These terminals are rated at

50VA, 120V.

4. Electrical

A. CAUTION: Hazard of severe shock. Make sure circuit

breaker and panel switch are in “off” position.

B. Make knockouts in control cabinet which are desired for final

wiring installation.

C. Connect leads from riser(s) to identified terminals shown on

Figure J.

D. TEMPORARY WIRING TO SIMULATE ACTIVATION OF

CONTROL CIRCUIT.

1. Jumper terminals S to S

1

.

2. Connect overtemperature control leads to terminals 5, 6, 7

or 8 as shown on Figure J.

3. Connect green ground wire lead from riser(s) to grounding

lug in control box and from control box to a suitable

ground.

4. Connect power cable of proper voltage to input of control

box.

5. Secure control box door, then place circuit breaker in “on”

position and energize heater with panel switch. Start with

45 second time interval and increase until a definite rise in

temperature on each heater tube can be felt with the bare

hand. NOTE: Adjustable time delay(s) in multi-stage units

have been preset at factory to provide steps for energizing

individual circuits.

6. Observe green light (which indicates “power”) when clos-

ing circuit breaker, first amber light with panel switch "on"

and subsequent amber light(s) (if any) at approximately 15

second intervals.

7. Have qualified electrician, using an amprobe, check amper-

age in individual heater leads to insure uniform amperage.

8. Turn circuit breaker to “off” position and remove tempo-

rary jumper from terminals Sand S

1

6

240

15

1

OCC-15-213

WCC-15-213

24

20

8

64

8

240

25

1

OCC-25-213

WCC-25-213

24

20

8

65

12

240

30

1

OCC-30-213

WCC-30-213

24

20

8

65

15

240

40

1

OCC-40-213

WCC-40-213

24

20

8

66

18

240

45

1

OCC-45-213

WCC-45-213

30

24

8

89

21

240

55

1

OCC-55-213

WCC-55-213

30

24

8

91

24

240

60

1

OCC-60-213

WCC-60-213

30

24

8

91

27

240

70

1

OCC-70-213

WCC-70-213

30

24

8

96

30

240

75

1

OCC-75-213

WCC-70-213

30

24

8

96

12

240

15

2

OCC-15-223

WCC-15-223

30

24

8

84

16

240

25

2

OCC-25-223

WCC-25-223

30

24

8

86

24

240

30

2

OCC-30-223

WCC-30-223

30

24

8

86

30

240

40

2

OCC-40-223

WCC-40-223

30

24

8

91

36

240

45

2

OCC-45-223

WCC-45-223

42

30

8

126

42

240

55

2

OCC-55-223

WCC-55-223

42

30

8

128

48

240

60

2

OCC-60-223

WCC-60-223

42

30

8

128

54

240

70

2

OCC-70-223

WCC-70-223

42

30

8

135

60

240

75

2

OCC-75-223

WCC-75-223

42

30

8

135

18

240

15

3

OCC15-233

WCC-15-233

36

30

8

113

30

240

25

3

OCC-25-233

WCC-25-233

36

30

8

120

36

240

30

3

OCC-30-233

WCC-30-233

36

30

8

125

45

240

40

3

OCC-40-233

WCC-40-233

36

30

8

127

6

480

10

1

OCC-10-413

WCC-10-413

24

20

8

64

8

480

15

1

OCC-15-413

WCC-15-413

24

20

8

64

15

480

20

1

OCC-20-413

WCC-20-413

24

20

8

64

18

480

25

1

OCC-25-413

WCC-25-413

24

20

8

64

21

480

30

1

OCC-30-413

WCC-30-413

24

20

8

64

27

480

35

1

OCC-35-413

WCC-30-413

24

20

8

64

30

480

40

1

OCC-40-413

WCC-30-413

24

20

8

64

12

480

10

2

OCC-10-423

WCC-10-423

30

24

8

84

20

480

15

2

OCC-15-423

WCC-15-423

30

24

8

84

30

480

20

2

OCC-20-423

WCC-20-423

30

24

8

84

36

480

25

2

OCC-25-423

WCC-25-423

30

24

8

89

42

480

30

2

OCC-30-423

WCC-30-423

30

24

8

91

54

480

35

2

OCC-35-423

WCC-35-423

30

24

8

91

60

480

40

2

OCC-40-423

WCC-40-423

30

24

8

96

18

480

10

3

OCC-10-433

WCC-10-433

36

30

8

113

36

480

15

3

OCC-15-433

WCC-15-433

36

30

8

113

45

480

20

3

OCC-20-433

WCC-20-433

36

30

8

113

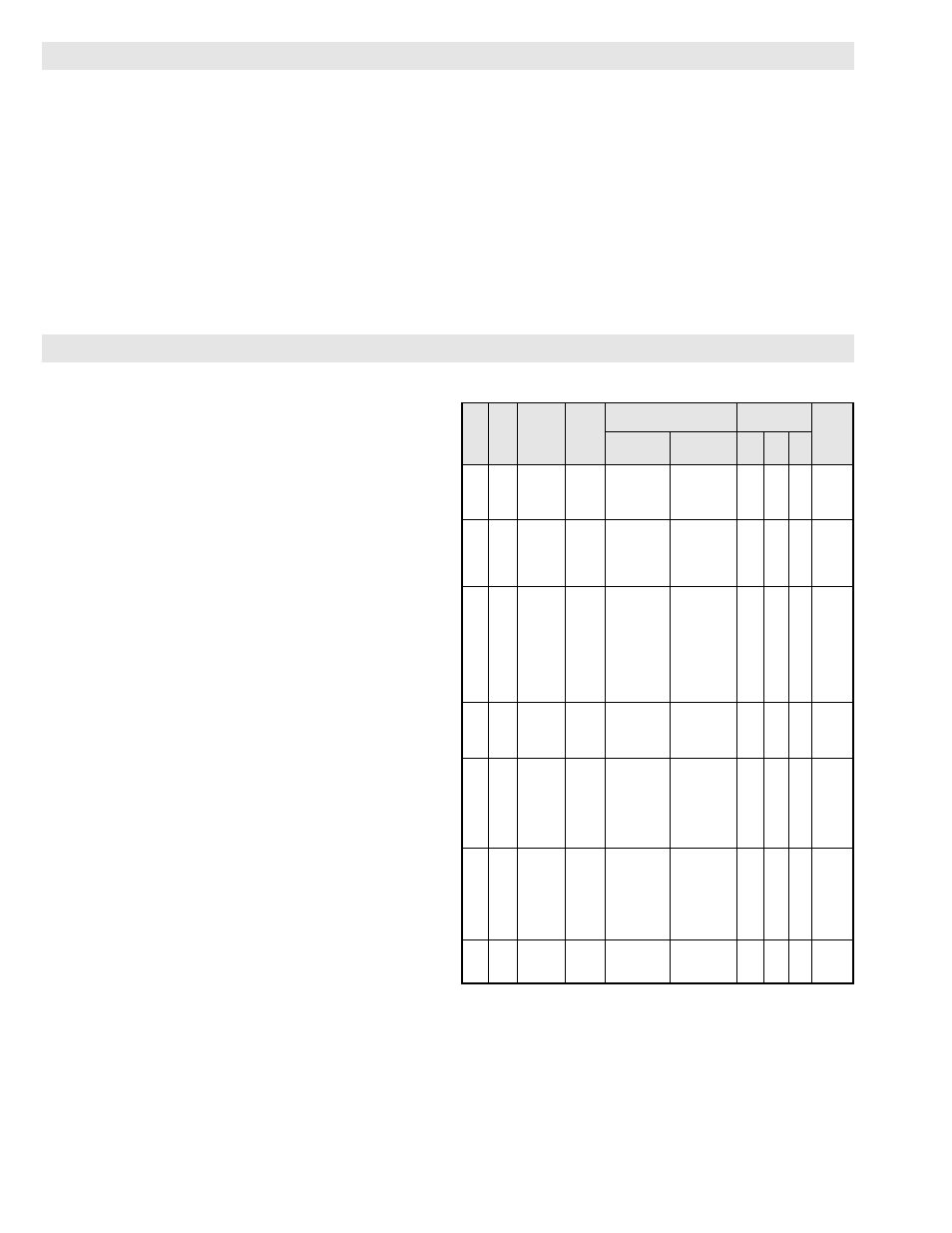

Catalog Number

Dimensions

Max.

No.

OCC

WCC

Inches

Approx.

Max.

Amps Per

of

Dust and Oil

Weatherproof

Net Wt.

kW

Volts

Circuit

Circuits Tight Models

Models

H

W

D

Lbs.

Specifications – OCC and WCC Control Center (All Phases)

6