Intek RheoVac DR User Manual

Page 17

- 15 -

3.7

CUSTOM SOFTWARE

Custom software may be developed by the user to receive and archive RheoVac DR data into a computer

system. The electronics has a serial data protocol of 9600 baud, no parity check, eight data bits and one

stop bit (i.e., 9600,N,8,1). Each transmitted group of data is sent in a standard ASCII coded format

representing each process variable value, instrument identification and status information.

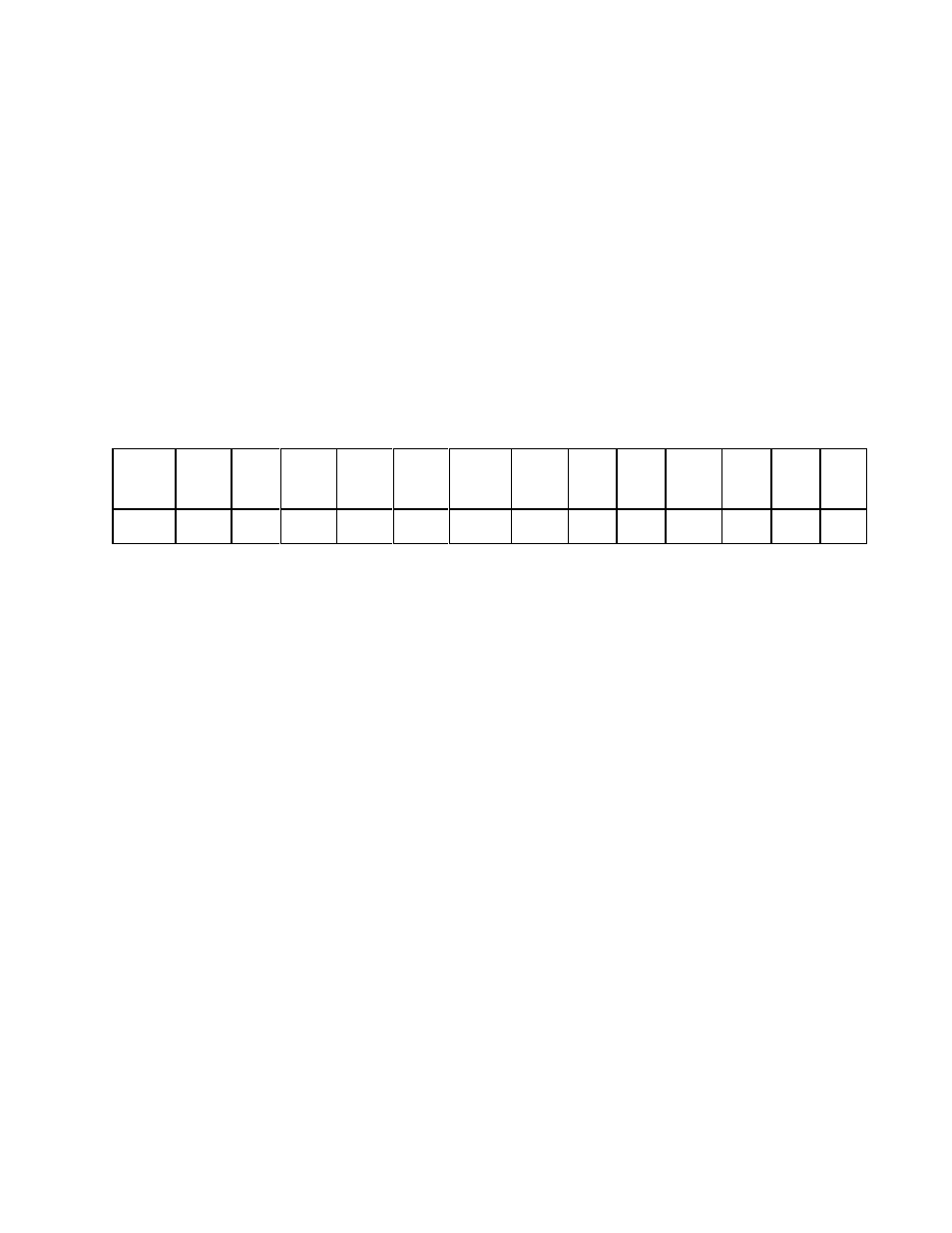

The data stream consists of 13 fields, followed by a carriage return

nine bytes each, are the process values. Following the process variables are the RheoVac serial number,

nine bytes, the process identification tag number, 15 bytes, and the RheoVac system status, seven bytes.

The data stream is then ended by a single

transmitted in each data stream is 122 bytes per probe including the trailing

group is sent approximately once every three seconds. Table V shows the field names and number of

bytes in one data stream.

TABLE V. Serial Output Data Stream

Actual

Volume

Flow

(A CFM )

Total

Mass

Flow

(lbs/hr)

Water

Vapor

Flow

(lbs/hr)

RheoVac

Press ure

("Hg abs)

Water

Vapor

Sp . V ol.

(Cu. ft/lb)

W ater to

Air Mass

Ra tio

(lb/lb)

Relative

Saturation

( %)

H

2

O

Partial

Press ure

("Hg abs)

Air

Mass

Flow

(lb/hr)

Probe

Temp.

(°F)

Instr.

Serial

Number

ID

Tag

No.

Status

Term.

< C R >

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

9

bytes

15

bytes

7

bytes

1

byte

Each of the first ten process values are sent in the fixed decimal format of XXXX.XXXX with leading

and trailing zeros inserted to maintain the nine character length. The next three fields are ASCII text

strings followed by the

be: 0010.0000, or 48,48,49,48,46,48,48,48,48 ASCII.