Great Planes Ultra Sport 1000 Kit - GPMA0425 User Manual

Page 22

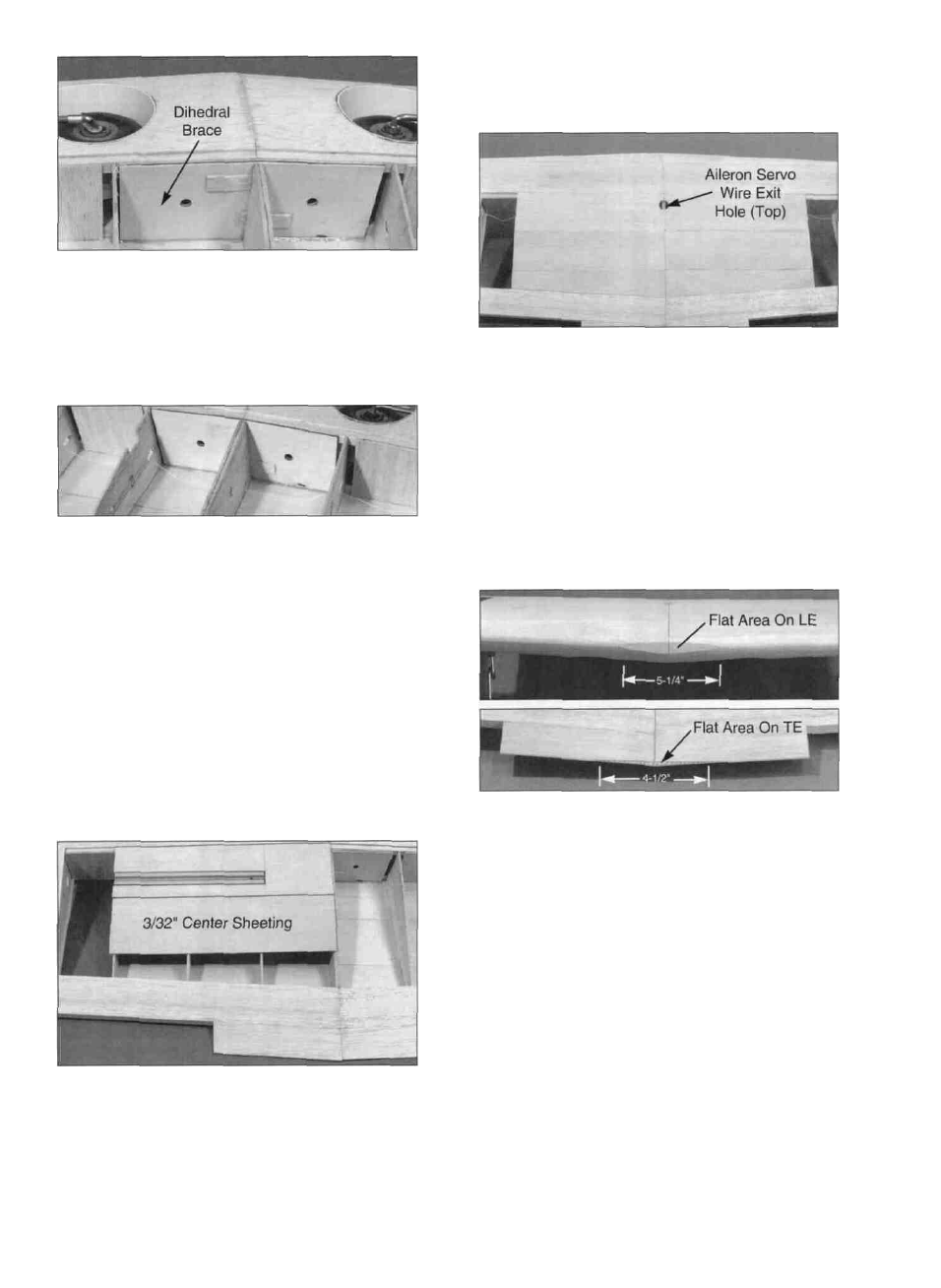

D 6 Using 30-minute epoxy, securely glue the

dihedral brace to the back of the spars Observe (in

the photograph) how two small balsa wedges were

used to hold the dihedral brace against the spars with

slight pressure Wipe off excess glue that may have

squeezed out onto the top of the spar. Let the glue

fully harden before proceeding.

D 7 You will later have to thread an aileron servo

extension wire through the holes in the ribs As an aid

in doing so, tie a 70" length of string to the aileron

servo rails in one wing panel and pass the string

through the servo wire holes in the W-6 through W-2

ribs Make a new hole in the W-1 ribs 1/2" behind the

spars and close to the top sheeting Pass the string

through the W-1 ribs and out the other wing panel and

tie it to the other servo rails Leave plenty of slack and

be sure you can reach the string through the servo

holes in the servo bay sheeting You will later cut a

hole in the top sheeting to expose this string, and you

will use this string to pull the servo wires through the

wing after the wing is covered.

D 9. Sand the wing joint smooth all around.

D 10 Now turn the wing right side up and cut a 1/2"

hole in the center of the top sheeting about 1/2"

behind the spars, for the servo wires to exit the wing.

This hole should include a section of W-1 so that it

provides access from one wing panel to the other, and

should expose the string which you installed in step 7

SAND "FLATS" ON LE AND TE

D 1. Study the wing plan near the wing centerline.

Note that the center portion of the LE and TE must be

sanded straight across to properly mate with the

formers in the fuselage

D 8 Using the remaining 3/32" x 3" x 11-1/8" sheets,

install the bottom center sheeting If you are using

tricycle gear you will need to cut a slot in the sheeting

to clear the main gear block.

D 2 Sand approximately 5/32" into the LE at the

centerline, and approximately 5/32" into the TE at the

centerline (The flats will end up approximately 5-1/4"

wide at the LE, and 4-1/2" wide at the TE)

FIBERGLASS THE CENTER SECTION

NOTE: Because of the high stresses in the center

of this wing, fiberglass reinforcement is

REQUIRED. Please do not omit this important

section!

NOTE: If you have previous experience with applying

fiberglass, feel free to use your favorite method,

providing that it results in a strong bond between the

glass cloth and the wood If this is your first time, we

offer the following suggested method, which is the

fastest and easiest we have seen.

22