Great Planes Ultra Sport 1000 Kit - GPMA0425 User Manual

Page 19

IMPORTANT NOTE: To insure a straight wing,

you must pin or weight the TE securely down on

the TE jig while the bottom sheeting is glued in

place!

D D 35 Sand a bevel on the front of the LE

sheeting, and glue it in place as previously done on

the top (When bending the sheeting down over the

ribs, use long strips of masking tape to hold the

sheeting down, rather than using heavy downward

pressure with your hands, to avoid introducing warps).

NOTE: If you are using fixed taildragger gear, you

will need to cut a slot in the sheeting to fit around the

main gear block If you are using retracts, you will be

sheeting over the retract mechanism If you have

installed retracts, use your measurements and

reference marks to locate and trim away the sheeting

at the center of the retract unit

DO NOT install the bottom center section sheeting

at this time.

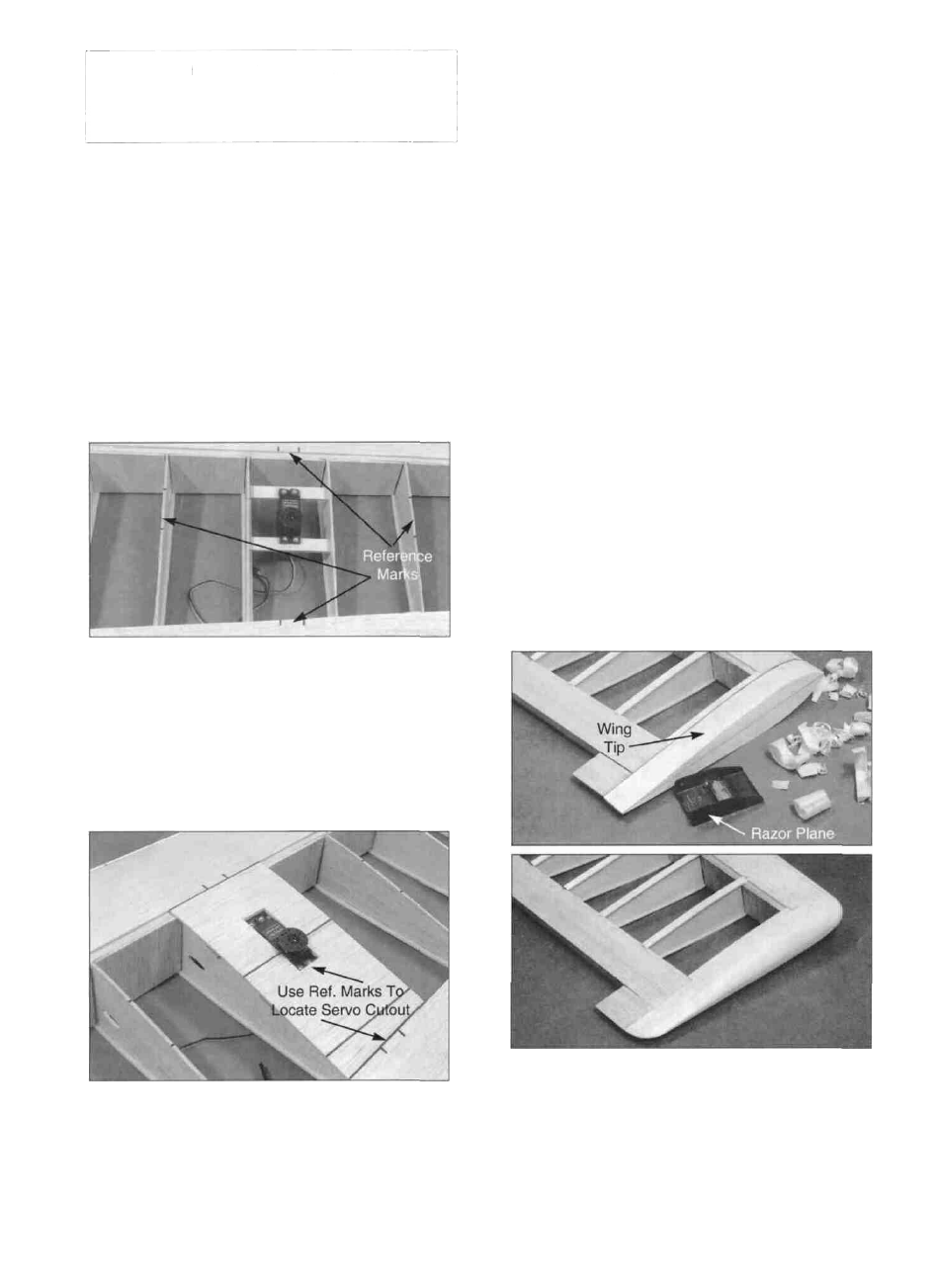

the TE sheeting, and it should extend about 1/8" past

the ribs on each side to simulate cap strips Cut a

hole in this sheeting over the servo rails just big

enough for the servo to pass through, then mount the

servo to the rails NOTE: For most standard servos,

this will result in the top of the servo case being flush

with the sheeting, with only a enough gap in the

sheeting at each end of the servo for servo installation

and access to the mounting screws.

D D 38. From the 3/32" x 3/8" x 36" balsa sticks, cut

and glue cap strips to ribs W-5, W-8, W-9, W-10, W-

11,W-12andW-13.

DO NOT install the bottom center section sheeting

at this time.

D D 39. Remove the wing panel from the building

board and re-check your glue joints Sand the

sheeting flush with ribs W-1 and W-13. Sand the TE

sheeting flush with the TE.

D D 40 Cut a 3" piece and a 6" piece off the 1-1/2" x

40" tapered balsa aileron stock and glue these pieces

to the tip and root ends respectively (see the wing

plan) IMPORTANT: When gluing these pieces,

make sure they line up equally with the top and bottom

surfaces of the wing Sand these pieces flush with W-

1 and W-13 and to blend smoothly with the wing.

D D 36. Glue the 1/8" x 1/2" x 3-1/4" ply aileron

servo rails into the slots in W-6 and W-7, spacing

them to fit your servo Temporarily mount a servo to

the rails. Make reference marks for the edges of the

servo on the LE and TE sheeting and on ribs W-5 and

W-8 which you will use in the next step Now remove

the servo.

D D 37. Using the 3/32" x 3" x 18" balsa sheet, cut

and glue pieces to the bottom of ribs W-6 and W-7

This sheeting covers the area from the LE sheeting to

D D 41 Glue the 1-1/4" x 1-7/8" x 11-5/8" balsa

wing tip to rib W-13 Then carve and sand it to the

shape shown on the plan. A razor plane and a

sanding block with coarse sandpaper will speed this

task.

19