Great Planes Super Chipmunk ARF - GPMA1303 User Manual

Page 9

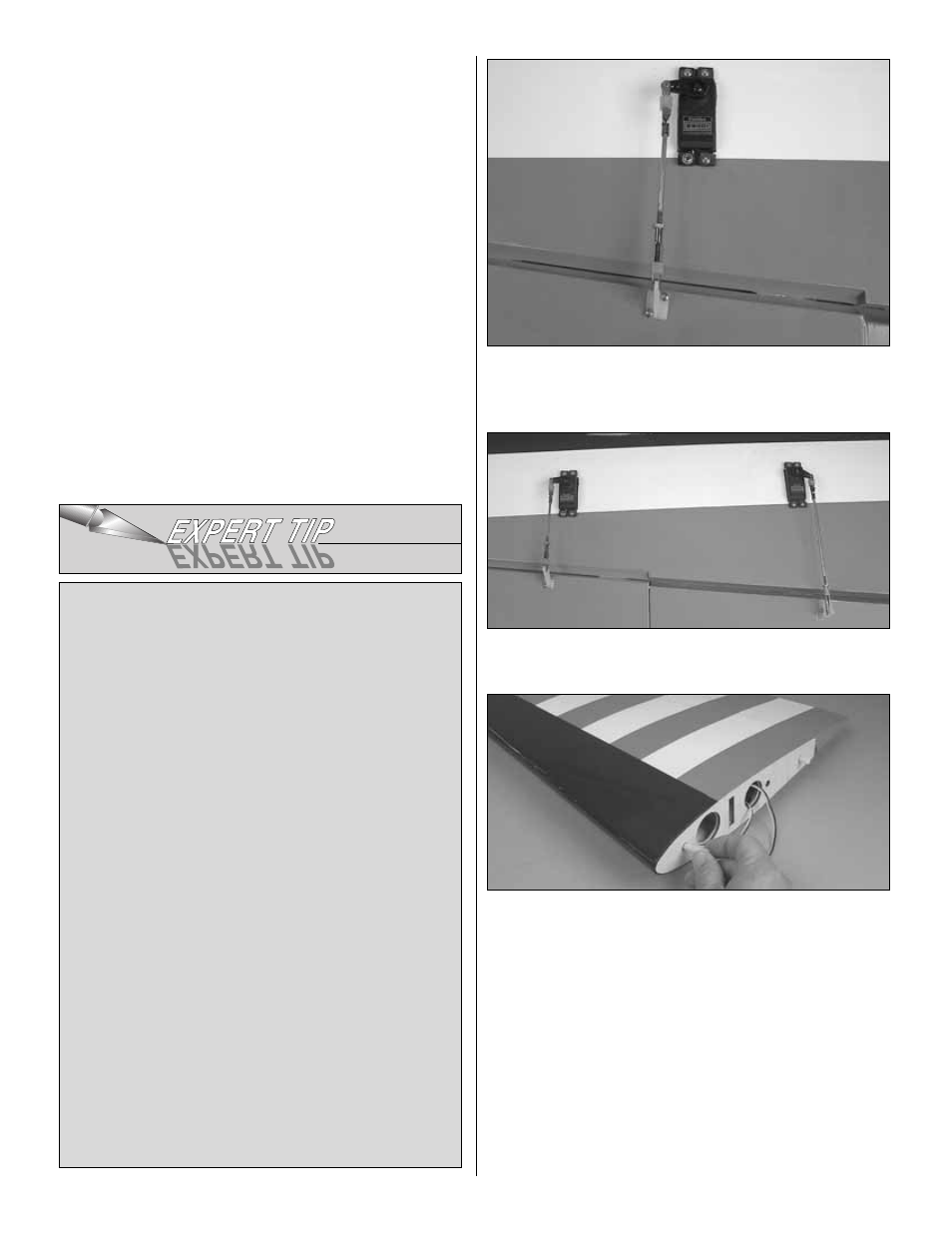

clevis retainer onto a threaded 4-40 metal clevis and then

screw the clevis onto the rod, tightening it against the nut.

Install the clevis onto the nylon control horn. Install an

unthreaded clevis onto the servo arm. Center the aileron.

Then, mark the threaded rod where it should be cut to fit the

clevis. Remove all of the pushrod components from the

servo and control horn. Read the

Expert Tip that follows.

Then, silver solder the clevis to the pushrod.

❏ ❏

8. After the rod has cooled, install a clevis retainer

onto the clevis you have just soldered. Then, install the

pushrod onto the aileron and servo.

❏ ❏

9. Using the same method, install the pushrod linkage

to the flap.

❏ ❏

10. Using 6-minute epoxy, glue two nylon anti-rotation

pins into the holes in the root of the wing. Each one should

extend from the wing approximately 1/2" [13mm].

❏

11. Repeat steps 1-9 for the left wing panel.

HOW TO SOLDER

1. Use denatured alcohol or other solvent to thoroughly

clean the pushrod. Use coarse sandpaper to roughen the

end of the pushrod where it is to be soldered.

2. Apply a few drops of soldering flux to the end of the

pushrod, then use a soldering iron or a torch to heat it. Tin

the heated area with silver solder (GPMR8070) by

applying the solder to the end. The heat of the pushrod

should melt the solder-not the flame of the torch or

soldering iron-thus allowing the solder to flow. The end of

the wire should be coated with solder all the way around.

3. Place the clevis on the end of the pushrod. Add another

drop of flux, then simultaneously heat the clevis and

pushrod. Slide the clevis the rest of the way onto the

pushrod as the solder melts. Apply another small amount

of solder while the pushrod and clevis are still hot. The

same as before, the heat of the parts being soldered

should melt the solder, thus allowing it to flow. Allow the

joint to cool naturally without disturbing. Avoid excess

blobs, but make certain the joint is thoroughly soldered.

The solder should be shiny, not rough. If necessary,

reheat the joint and allow to cool.

4. Immediately after the solder has solidified, but while it

is still hot, carefully use a cloth to quickly wipe off the flux

before it hardens. Important: After the joint cools, coat

with oil to prevent rust. Note: Do not use the acid flux that

comes with silver solder for electrical soldering.

9