Great Planes Christen Eagle ARF - GPMA1217 User Manual

Page 24

❏

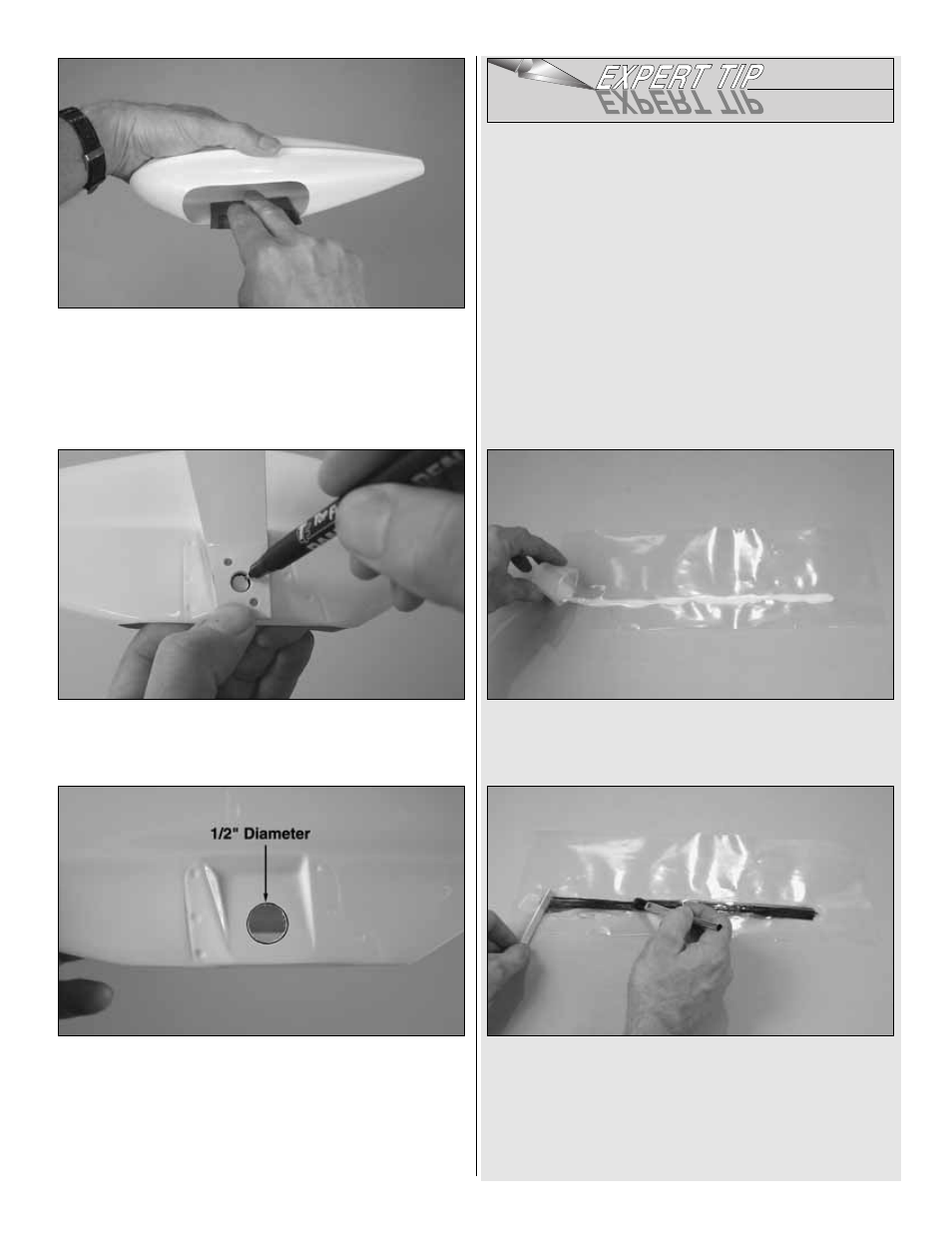

1. The same as was done for the cowl, wipe the inside of

the wheel pants where the plywood braces will go with

paper towel squares dampened with denatured alcohol. Use

coarse-grit sandpaper to roughen the inside of the wheel

pants in the same area.

❏

2. Mark the location of the axle hole in the left side of the

landing gear onto the left wheel pant.

❏

3. Use a rotary tool with a cutting bit to cut a 1/2" [13mm]

hole centered over the hole marked in the previous step.

❏

4. Mark and cut the hole in the right wheel pant the same way.

❏

5. Follow the Expert Tip that follows if you would like to

add additional reinforcement in the wheel pants.

How to “Bullet-Proof” Your Wheel Pants

Here’s a way to add rigidity to the wheel pants and increase

their service life. They still may not hold up to a crash, but

they will survive the day-to-day rigors of bouncy landings

and rough runways. This could get messy, so take

precautions and wear a shop apron and rubber gloves. The

instructions show how to do one pant at a time, but they

could be done simultaneously.

❏

A. Thoroughly sand the inside of the wheel pants where

the carbon fiber will go. Cut an approximately 13" [330mm]

long, 3/8" [10mm] wide “swatch” of Dave Brown Carbon Fibre

Tape (DAVR2000).

❏

B. Mix approximately 1/4 oz. of 30-minute epoxy. Pour a

bead of epoxy onto an approximately 16" [400mm] sheet of

plastic (leftover from the kit packaging or another plastic bag).

❏

C. Lay the carbon fiber swatch onto the bead of epoxy.

Let it sit there for a minute or so. Holding one end of the

carbon fiber with an epoxy mixing stick, use an epoxy brush

to work the epoxy up through the fibers.

❏

D. Apply a light coating of epoxy to the inside of the wheel

pant all the way around the wheel opening.

24