Cover the model with monokote – Great Planes T-Craft 20 Kit - GPMA0155 User Manual

Page 41

❏ ❏

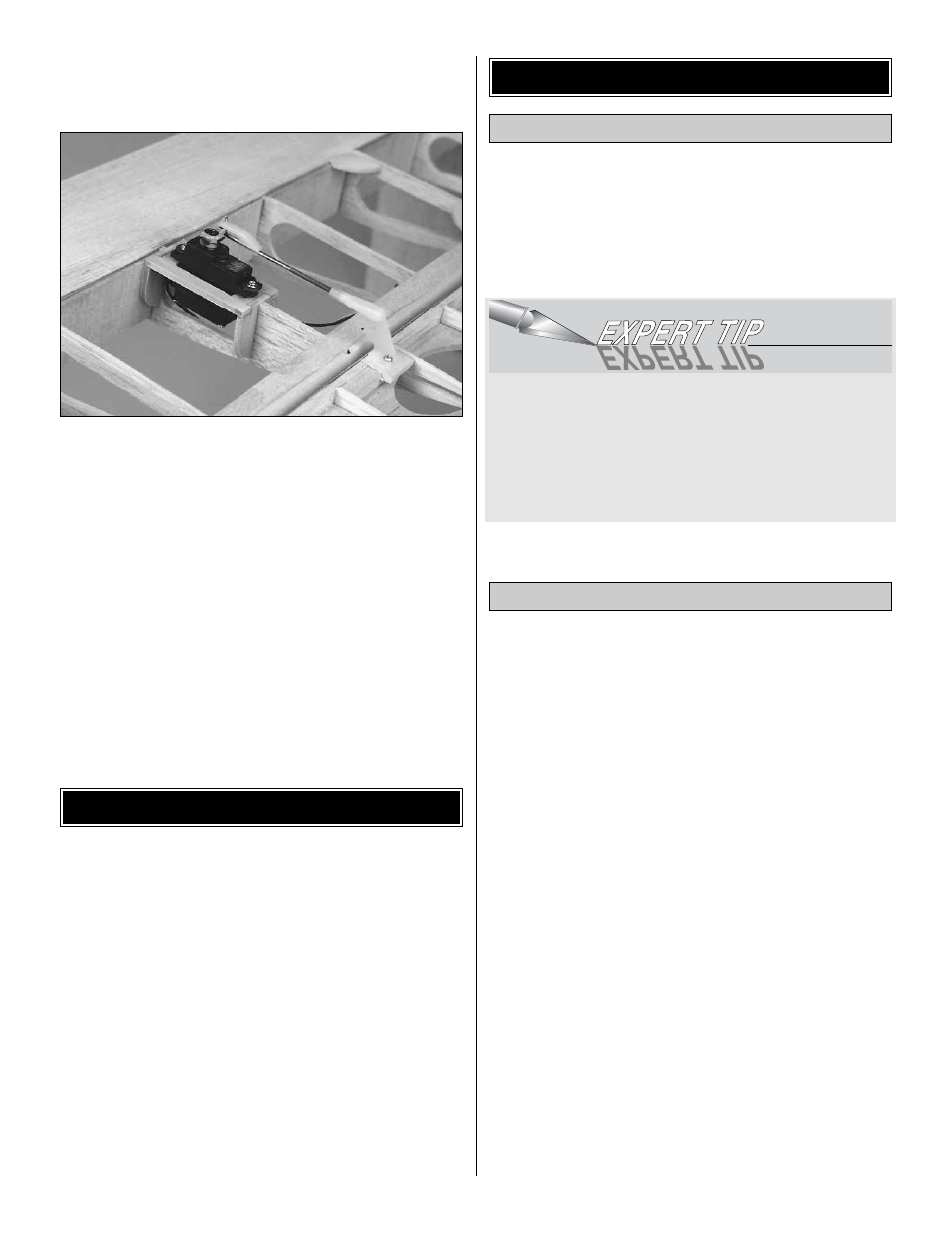

4. With the aileron servo centered and the aileron in the

neutral position, use a felt-tip pen to mark where the aileron

pushrod crosses the mounting holes in the servo arm.

❏ ❏

5. Make a 90 degree bend at the mark you made.

Temporarily install a nylon FasLink on the pushrod and cut

the wire so it slightly protrudes out of the FasLink.

❏ ❏

6. Remove the two #2 x 3/8" sheet metal screws from

the control horn. Put a couple of drops of thin CA into both

screw holes in the aileron to strengthen the wood. After the

CA cures, reattach the control horn.

❏

7. Return to step 1 of

Install the Aileron Pushrods and

install the other aileron servo and pushrod.

SPECIAL NOTE: Do not confuse this procedure with

“checking the C.G.” or “balancing the airplane fore and

aft.”That very important step will be covered later in the

manual. Now that you have the basic airframe nearly

completed, this is a good time to balance the airplane

laterally (side-to-side). Here is how to do it:

❏

1. Temporarily attach the wing and engine to the fuselage.

❏

2. With the wing level, lift the model by the propeller shaft

and the bottom of the rudder (this may require two people).

Do this several times.

❏

3. If one wing tip consistently drops when you lift the

plane, it means that side is heavy. Balance the airplane by

gluing weight to the inside of the other wing tip. Note: An

airplane that has been laterally balanced will track better in

loops and other maneuvers.

Fill any scuffs and dings with balsa filler or by “expansion.” See

Expert Tip below. After the filler has dried, use progressively

finer grades of sandpaper to even and smooth all the edges,

seams and surfaces. Sand a radius along the bottom edge of

the fuse. Remove all the balsa dust from the model with

compressed air, a tack cloth or a vacuum with a brush.

Many surface blemishes on a framed model are caused by

bumps and balsa chips on the work surface. This type of

“ding” is best repaired by applying a drop or two of tap

water to the blemish, then running a hot sealing iron over

the spot to expand the wood fibers. After the surface has

dried, sand the expanded area smooth.

The T-Craft does not require much painting to obtain the

scheme shown on the box, as most of the finish is done with

Top Flite MonoKote covering. The only painting required is

the cowl, windshield frame and wheel pants.

The technique we will describe here is how the model

pictured on the box was finished. Remove the engine,

landing gear, windshield and control horns.

Cover the model with Top Flite MonoKote film, using the

sequence that follows. The use of a Top Flite MonoKote Hot

Sock

™

on your covering iron will prevent scratching the

MonoKote film.

Before you cover the fuselage, first apply 1/4" wide strips of

white MonoKote film in the corners where the stab and fin

meet the fuselage. Proceed to cover the stab with pre-cut

pieces that meet in the corners and overlap the 1/4" strips.

Do not, under any circumstances, attempt to cut the

covering on the stab after it has been applied except

around the leading and trailing edges and the tips.

Modelers who do this may cut through the covering and into

the stab. This will weaken the structure to a point where it

may fail during flight.

Some modelers prefer to cover the top and bottom of the

ailerons with one strip of MonoKote film. This is done by

covering the bottom first, then wrapping the MonoKote film

up over the leading edge.

Cover the Model with MonoKote

®

Film

Final Sanding

FINISHING

BALANCE THE AIRPLANE LATERALLY

41