Fuses, Routine safety tests – Grant Instruments LTC4 User Manual

Page 34

31115 V1

LTC4

Page 33

Operating Manual

www.grantinstruments.com

Clean the outside of the equipment with a damp cloth, using water only. Do not use

chemical cleaning agents. Before using any other cleaning or decontamination method,

check with Grant Instruments or your local representative to make sure that the proposed

method will not damage the equipment. Scale on immersed parts can be removed using

chemical de-scaling products designed for use on equipment that has metal parts.

De-scaling products may be toxic and manufacturer

’s instructions should

always be followed

9.3

Fuses

The control unit fuses are internal and should not need to be replaced. Please contact

the Grant Instruments service department if the unit has a fuse fault.

The refrigeration unit has externally accessible fuses that can be changed by a qualified

technician. Disconnect the unit from the power supply socket. Remove the IEC power

plug from the rear of the unit. Press down the fuse drawer catch and pull out. Check

fuses and if necessary replace. Push the fuse drawer back in until fully engaged and

replace the IEC plug.

Replacement fuses must be 1.25” x 0.25” anti surge ceramic type with the rating defined

in the following table:

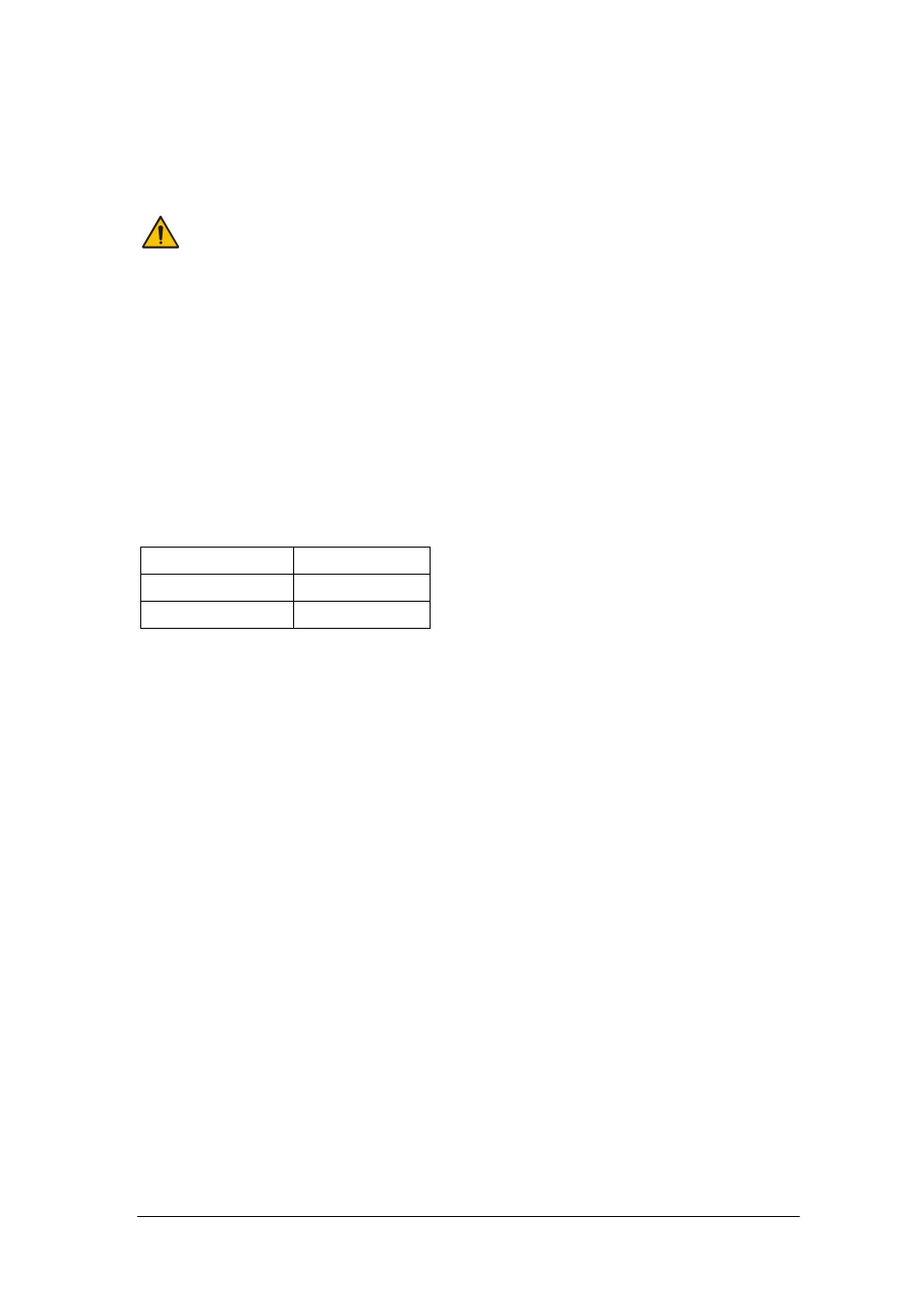

R unit

Fuse rating

R4

5AT

R4L

10AT

Fuse replacement should only be carried out by a competent person.

9.4

Replacing the mains cord

Any replacement mains cords used for the control unit or refrigeration unit must meet the

same specification as the one originally supplied to maintain the safety of the unit.

All 230V mains cables must have the following markings;

70°C for the R unit and

carry 10A. The mains plug and IEC connector must carry approvals from a European

certification body (e.g. BSI, VDE or equivalent).

The LTC4L (120V) refrigeration units have fixed mains cords which should not be

replaced.

9.5

Routine safety tests

If routine tests are to be made, we recommend a test of the integrity of the protective

earth conductor and an insulation test at 500V DC. Routine flash tests are not

recommended for any electrical equipment, because repeated high voltage tests degrade

insulation materials.