FloAire INDIRECT FIRED BENT TUBE MODULE User Manual

Page 9

9

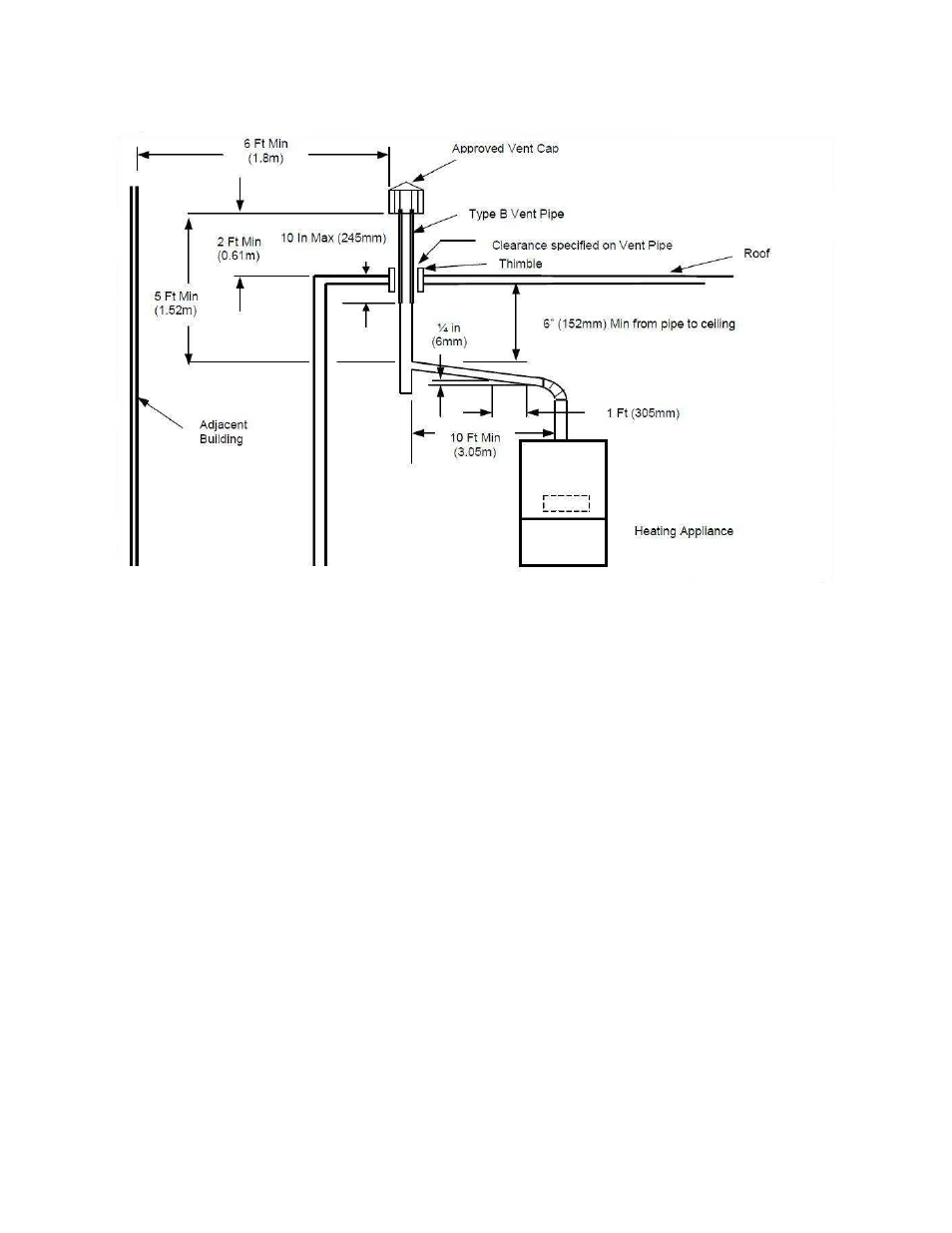

Vertical Venting

Horizontally Vented Furnaces – Category III

Horizontal vent systems terminate horizontally (sideways)

WARNING: Do not use Type B vent within a building on horizontally vented units.

1. All vent pipe joints must be sealed to prevent leakage. Follow the instructions provided with the

approved venting materials.

2. The total equivalent length of vent pipe must not exceed 50 ft. (15.25m). Equivalent length is the total

length of straight sections, plus 5 ft. (1.52m) for each 90⁰ elbow and 2.5 ft. (0.76m) for each 45⁰

elbow.

3. The vent system must also be installed to prevent collection of condensate. Horizontal runs should be

pitched upward ¼ in. per foot (21mm/m) and should be supported at three (3) foot (1m) maximum

intervals.

4. Insulate vent pipe exposed to cold air or routed through unheated areas. Insulate vent pipe runs

longer than 10 ft. (3m). Insulation should be a minimum of ½ in. (12mm) thick foil faced fiberglass of 1

½ # density. Maintain 6 in. (152mm) clearance between vent pipe and combustible materials.

5. An approved Breidert Type L, Field Starkap or equivalent vent cap must be provided. Vent cap inlet

diameter must be the same as the vent pipe diameter.

6. The vent terminal must be at least 12 in. (305mm) from the exterior wall that it passes through to

prevent degradation of building material by flue gases.

7. The vent terminal must be located at least 12 in. (305mm) above grade, or in snow areas, at least 3

ft. (1m) above snow line to prevent blockage.

8. The vent terminal must be installed with a minimum horizontal clearance of 4 ft. (1.2m) from electric

meters, gas meters, regulators or relief equipment.