Sequence of operation – FloAire INDIRECT FIRED BENT TUBE MODULE User Manual

Page 23

23

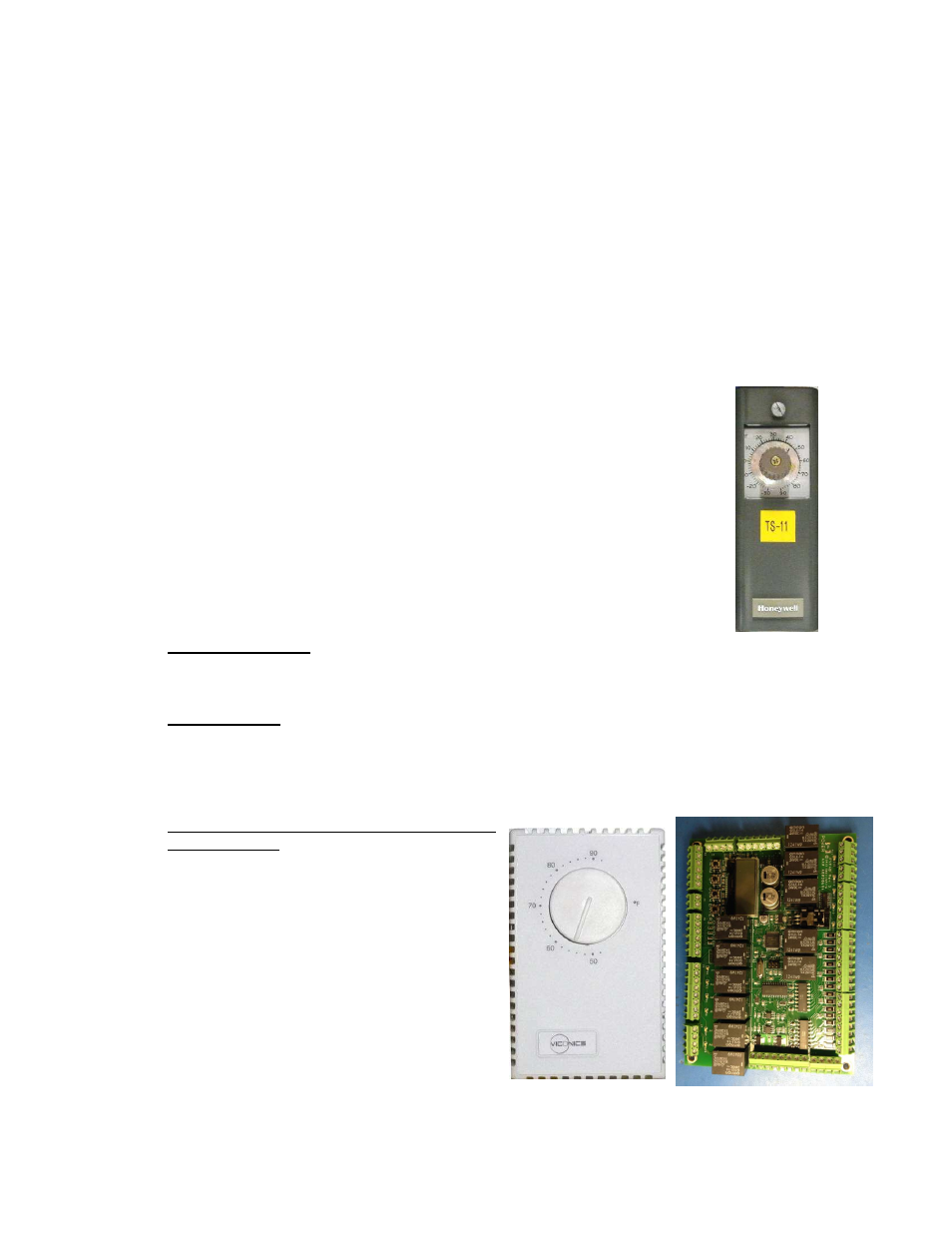

FVFAB

Temperature

Selector Dial

Intake Air

Thermostat

Sequence of Operation

The Indirect-fired heater is most easily understood when broken down into smaller individual systems.

There are two main systems; a make-up air fan and a heater. The make-up air fan consists of a heavy-

duty blower and motor. The heater may be further broken down into two control systems, the Modulating

Gas System (MGS) and the Flame Safety Control (FSC). The burner mixes air with the gas (Natural or

Propane) which heats a heat exchanger which heats the air. There are between one and four furnaces in

each heater depending on the total required heating output capacity for the application. Included in every

unit is at least one modulating furnace, located furthest downstream, closest to the discharge of the

heating module. The modulating furnace(s) and additional On/Off furnaces (if used) are controlled using

vernier-type modulation methods resulting in fully linear heating output over the entire gas-firing range.

Modulating Gas System

The first system, the Modulating Gas System, consists of an Intake Air Thermostat,

a Temperature Selector Dial, a Functional Vernier Functional Auto Balancing

Module (FVFAB), a Discharge Air Sensor (only on discharge temp control option), and a

modulating gas valve(s). The Intake Air Thermostat is only used to give a call for heat

signal to the Flame Safety Controller. It is important to understand that this intake air

thermostat is only used for this purpose and does not control the discharge/space

temperature in which the module tries to maintain. For Kitchen MUA heating

applications, the dial setting on the Intake Air Thermostat should be set at 45 °F,

whereas the Temperature Selector Dial should be set at 55 °F. For all other

applications, the dial settings should be set appropriately based on the end-users

preferences and on-site conditions.

There are 3 different options for controlling the gas firing output of these units. These

include Discharge Temperature Control, Space Temperature Control, and Building

Automation Control. Refer to page 24 for how to configure for each type of control:

1. Discharge Control: When wired for discharge control, the thermostat utilizes a discharge air

sensor in the unit and heats the incoming air to the selected setting on the Temperature Selector

Dial or programmable stat by sending signal voltage to the FVFAB.

2. Space Control: When the space control option has been selected, the Temperature Selector

Dial or programmable stat is mounted in the space, sensing the temperature in the room with use

of

an internal sensor. The discharge sensor in

the unit is not used and the stat sends a signal

voltage directly to the FVFAB.

3. Building Automation Control/Direct Digital

Control (DDC): Use of the Temperature

Selector Dial is completely eliminated and a 0-

10vdc or 0-20mA signal is sent to the FVFAB

from the building control system to regulate the

heating output of the unit.

In all cases, the FVFAB controls the amount of

gas to the burner based on the signal from the

temperature control components. When the

modulating gas valve is all the way open and

achieving the maximum BTUs and temperature

rise of the unit, it is called “high fire”.