Dynaflite DYFA3901 User Manual

Page 9

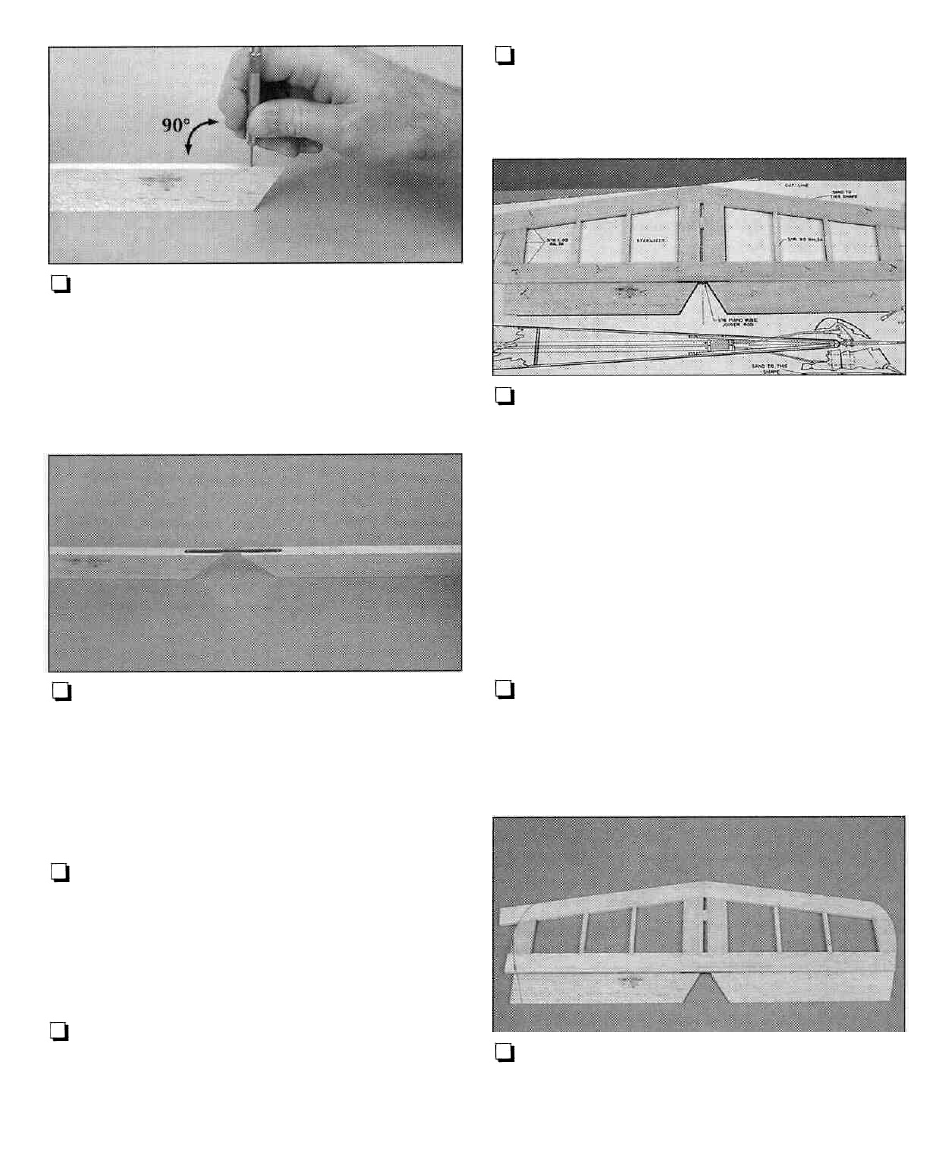

Q 10. Drill 1/16" holes, 9/16" deep, in the

leading edge of the elevators at the marked

locations. Make sure the two holes are perpendicular

to the leading edge. Be careful that the drill bit does

not break through the sides of the elevators.

Q 14. For a more secure fit, file or grind four or

five notches in each arm of the elevator joiner wire.

Thoroughly clean the joiner wire with isopropyi alcohol.

Q 15. Pack 30-minute epoxy into both elevator

joiner wire holes and in the groove on the leading

edge of the elevators. Install the joiner wire in both

elevators. Wipe off any excess epoxy with a paper

towel dampened with isopropyi alcohol. Before the

epoxy cures, place a piece of wax paper over the

joiner wire and pin the elevators flat to the building

board with the leading edge against the trailing

edge of the stabilizer.

Q 11. Cut a small groove from the hole to the

inboard end of the elevators. Gradually deepen the

groove until the joiner wire fits flush with the leading

edge of the elevators. With the elevator joiner wire

installed, the wire must be flush with the leading

edge of the elevators.

Q 12. With the joiner wire installed in the

elevators, place the assembly on a flat surface.

MAKE SURE both elevators lie flat. If they do not,

remove the joiner wire and twist it slightly. It is very

important that both elevators lie flat.

U 13. Remove the joiner wire. Mark a centerline

on the leading edge of both elevators and carefully

sand the leading edges to a "V shape as shown on

the fuselage plan.

Q 16. Remove the elevator and stabilizer from the

building board after the epoxy has cured.

1-J 17. Draw the outline for the tips on the stabilizer

and elevator using the plan as a pattern. Cut and

sand the stabilizer and elevator tips to shape.

9