Dynaflite DYFA3901 User Manual

Page 11

NOTE: The control horn in the photo was painted for

clarity (The control horns in the kit are made of while

plastic).

Q 7. Insert two 2-56 x 1/2" machine screws

through the horn base and elevator. Place the nut

plate on top of the elevator and thread the machine

screw into the nut plate.

Ul 8. Remove the nut plate and control horn.

Reinforce the elevator by applying a couple of drops

of thin CA on the elevator where the control horn

is mounted.

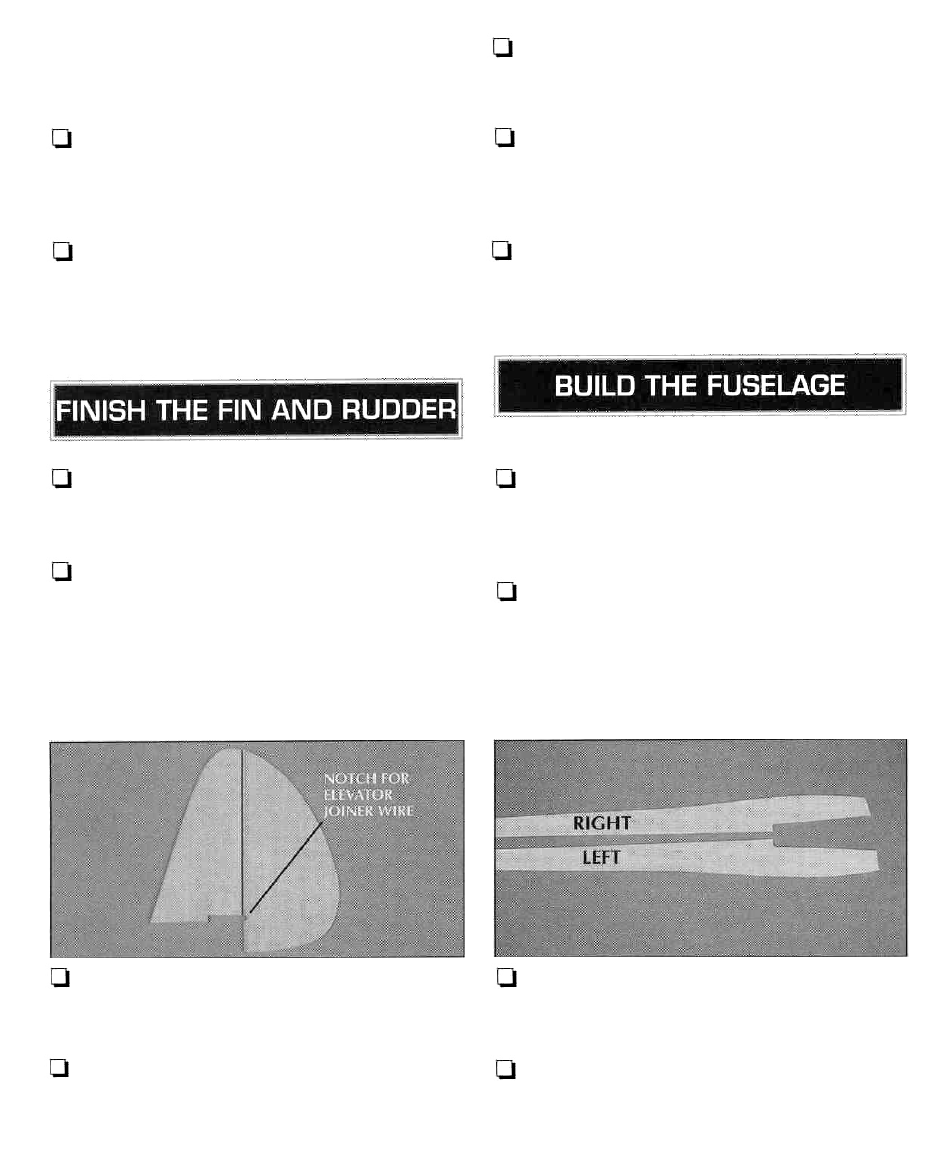

Ul 5. Sand a radius on the leading edge of the fin

as shown on the cross section view.

Q 6. Mark and install the hinges following the

same procedure used on the stabilizer and elevator.

DO NOT glue the hinges in at this time.

Q 7. Install the control horn on the rudder following

the same procedure used with the elevator.

Q 1. Draw a centerline completely around the edge

of the shaped balsa rudder. This will help keep the

rudder symmetrical while sanding.

Q 2. Carefully sand the shaped balsa fin and

rudder to the shape shown on the fuselage cross

section. NOTE: The weight of the fin and rudder can

be reduced by cutting lightening holes in them as

shown on the plan. This may reduce the weight

required in the nose to balance the sailplane.

[.-I 1. Place wax paper or Great Planes Plan

Protector over the fuselage plan to prevent glue

from sticking to the plan.

Q 2. Put the two die-cut 3/32" balsa fuselage

sides together and check that they are the same size

and shape. If not/ lightly sand them. Compare the

fuselage sides to the fuselage plan.

Q 3. Cut a notch in the leading edge of the rudder

to clear the elevator joiner wire as shown on the plan.

Q 4. Sand a "V" on the leading edge of the rudder.

Use the cross section view as a guide.

[-1 3. Lay the fuselage sides top edge to top edge as

shown. Mark one fuselage side left and the other right.

Q 4. Lightly sand the edges of the die-cut 1/8"

plywood fuselage doublers.

11