Dynaflite DYFA3901 User Manual

Page 23

end of the wing tip. While holding the wing leading

edge and trailing edge at rib W-4 firmly against the

flat surface, shrink the covering. This will put a slight

twist in the wing called "washout." This washout will

help prevent tip stalls when flying.

After all the covering on the wing is shrunk, iron the

covering to each wing rib.

LJ 1. Center and glue the two 3-3/4" wing hold

down dowels in the fuselage.

U 2. Set the wing on the fuselage and secure it to

the fuselage by hooking a couple of rubber bands

(not included) over the forward dowel, stretching the

rubber bands over the wing and hooking them over

the aft dowel. Again, set the stabilizer in the

stabilizer saddle. Check the alignment of the

stabilizer with the wing from the front and rear of

the model. Use a tape measure to set the stabilizer

tips equal distance from the nose.

U 3. Use 30-minute epoxy to glue the stabilizer in

position on the fuselage, rechecking the alignment

before the epoxy cures.

Q 4. Remove the covering from the bottom 3/16"

of the fin. Be very careful not to cut into the fin. Test

fit the fin in the slot at the aft end of the stabilizer.

The trailing edge of the fin should be flush with the

trailing edge of the stabilizer. When satisfied with

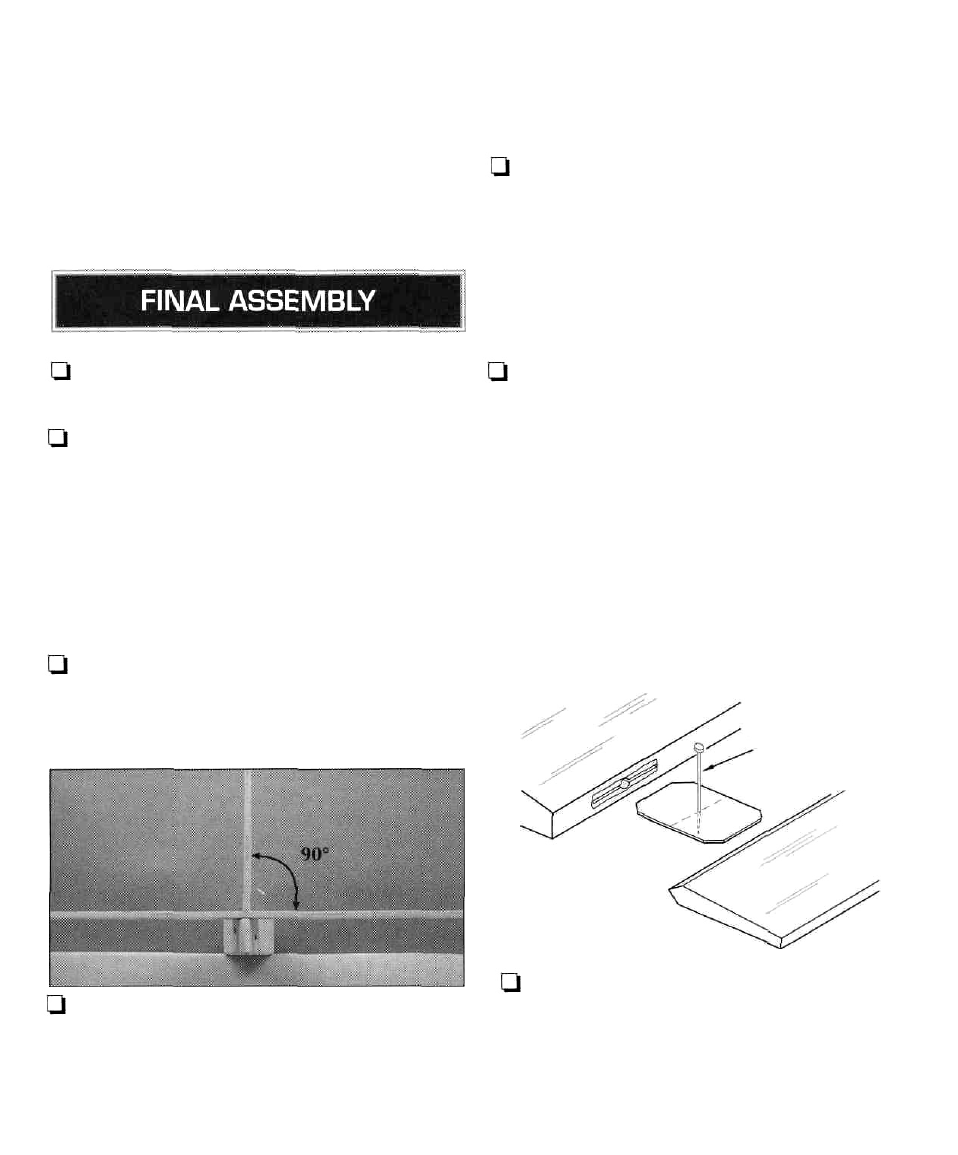

the fit, glue the fin to the stabilizer with 30-minute

epoxy or aliphatic resin. Make sure the fin is 90° to

the stabilizer. Masking tape and T-pins can be used

to hold it in place while the epoxy cures.

5. Cut and shape the 3/32" x 1/4" x 10-3/4"

basswood nose and tail skid. Bevel the forward

face of the nose skid before gluing it on. Place the

skids in position and mark the outline of the skids on

the fuselage. Carefully remove the covering from

inside the outline. Glue the skids on the fuselage

with thick CA. The skids may be varnished or

painted after installation.

d 6. Starting with the elevators and stab/ cut the

covering from the hinge slots.

The most common mistake made by modelers when

installing a CA type of hinge is not applying a

sufficient amount of glue to fully secure the hinge

over its entire surface area; or, the hinge slots are

very tight, restricting the flow of CA to the back of

the hinges. This results in hinges that are only "tack

glued" approximately 1/8" to 1/4" into the hinge

slots. The following technique has been developed to

help ensure thorough and secure gluing.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

1 7. It is best to leave a very slight hinge gap,

rather than closing it up tight, to help prevent the

CA from wicking along the hinge line. Make sure

the control surfaces will deflect to the recommended

throws without binding. If you have cut your hinge

slots too deep, the hinges may slide in too far,

22