Dynaflite PT-19 User Manual

Page 24

8. Glue the fin and fin fairing blocks into position

with 30-minute epoxy. Be sure the fin is

perpendicular to the stab and aligned with the

fuselage centerline.

9. When the epoxy has cured, remove the wing.

Fill in and blend any areas that need it with leftover

wood and hobby filler.

10. Mount the tailwheel bracket to the fuselage

with three #2 sheet metal screws. Use leftover wood

and hobby filler to blend it to the fuselage.

11. Finish the cockpits. The cockpit area was

designed to be structure free so you can add as

much detail as desired. The simplest is to glue in

cockpit decks as shown on the plans and add a

couple of Williams Brothers pilots glued to the decks.

Fourmost makes cockpit coaming that dresses up the

openings nicely. The kit includes two instrument

panel decals which can be positioned on the

bulkheads, or you can purchase separate instrument

panels from Midwest Products. The kit also includes

25" of 1 /4" dowel to build the roll cage between the

cockpits. Details in the cockpit area will really dress

up the appearance of your model.

Position the mount on the plans at the firewall then

locate the engine on the mount to fit the front of the

cowl properly. Check the position on the model to be

sure blind nuts and bolts will clear the structure.

NOTE: If you will be using a chainsaw-type engine,

such as the G-23, your engine will need to be

spaced out from the firewall. On one of our

prototypes we used a 1-1/2" block of wood that

was bolted to the firewall with 10-32 x 2" bolts.

13. Glue the firewall to the fuselage with

30-minute epoxy. For added security you can pin the

firewall to the fuselage if desired. Drill small holes

through the sides of the fuselage into the firewall and

epoxy in small dowels or toothpicks.

14. Once the epoxy has cured, install your

engine and mount on the firewall.

15. Fit the cowl. The plastic cowl comes in halves

and needs to be glued together. The kit includes a

strip of plastic that is used to reinforce the joint on

the inside. Thin CA works well for this. When you

have glued the cowl together, cut a small hole where

the prop needs to exit the front. Slip the cowl onto

the fuselage. Enlarge the hole as needed to clear the

engine thrust washer. As you continue to fit the cowl

to the fuselage and engine you may need to remove

and reinstall the engine several times. We have

found that using a piece of cardboard taped to the

side of the fuselage is the easiest way to locate the

cutout for the engine. Tape the cardboard to the

fuselage and cut an opening in it to fit your engine,

remove the engine, install the cowl and transfer the

cutout to the cowl. If you go slowly and remove a

little material each time from the cowl you will be

rewarded with a good looking cowl.

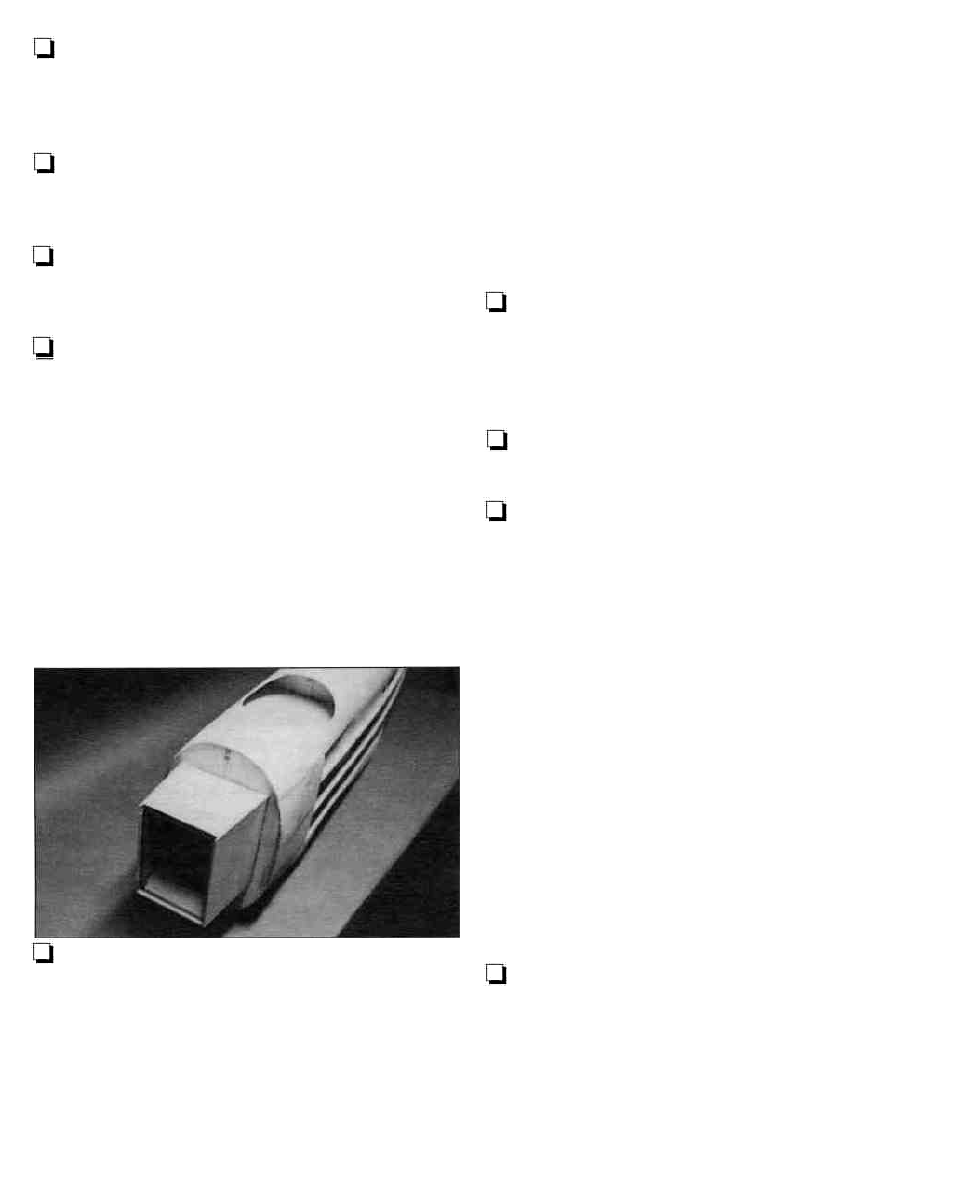

12. Time to mount your engine. Before you glue

the firewall into position, you should add some

reinforcing sticks to the inside of the fuselage as

shown in the above photo. There should be ample

leftover 1 /4" x 3/8" basswood sticks for this purpose.

Glue them into position with 30-minute epoxy. While

you are waiting for the epoxy to cure you can mount

your engine to the engine mount you have chosen.

16. When you are satisfied with the fit of the

cowl remove it and glue the four hardwood blocks

into place on the fuselage. The blocks are of different

sizes so a little fitting will be needed. They should be

close to fitting from the engine box to the fuselage

curve at "B." After the blocks are glued into position,

sand them to blend to the curve of the cowl.

24