Dynaflite PT-19 User Manual

Page 15

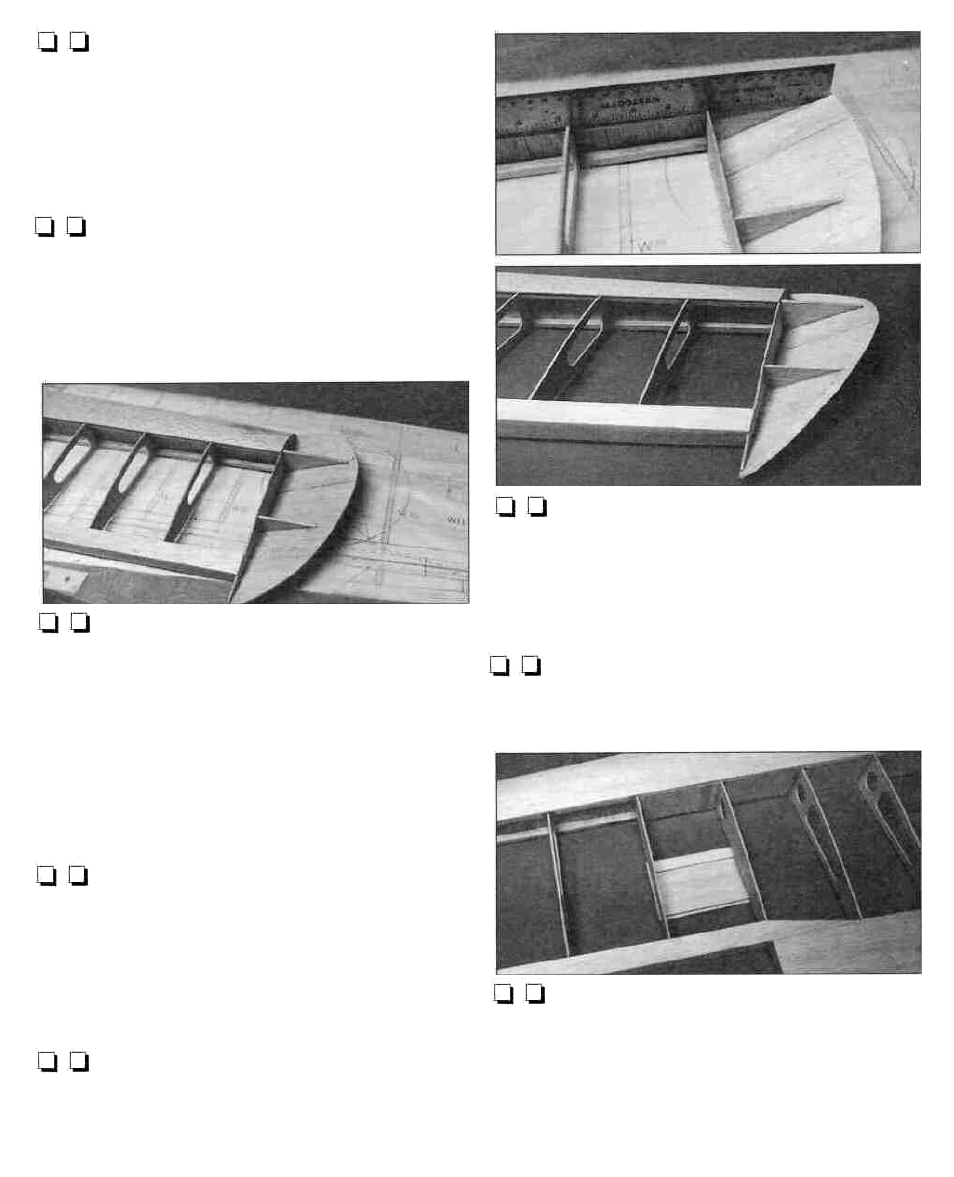

27. After the glue has dried, turn the wing

over and fit and glue a 3/32" x 15/16" x 24" sheet

to the trailing edge between W5 and W11 with

aliphatic resin. You will have to trim the 3/32" x 3"

sheet installed in step 12.

28. Trim the LE and TE sheeting even with ribs

W1 and W11. Sand the tip and root of the wing so

that it is smooth and flat.

29. Prepare the wingtip for sheeting. Fit and

glue the 1 /8" die-cut balsa stiffeners to W11. The

smaller stiffener should be positioned so that the top

and bottom of the stiffener are flush with the top and

bottom edges of rib W11. The larger stiffener should

be flush with the bottom of the rib and the top

surface of the top spar. Use a long straightedge to

check that the top edge of the stiffeners are parallel

to the top surface of the wing.

30. Cut the wing tip pattern from the center of

this manual. Use the soft 1/8" x 3" x 36" balsa

sheet to cut the pieces for the wing tip to match the

pattern, noting the grain direction. Glue the pieces

together and sand both surfaces flat and smooth.

31. Fit and glue the tip to the bottom of W11

and the stiffeners. Fit and glue a filler block from

leftover balsa to the wing tip at the leading edge.

32. Cover the tops of ribs W7-W11 with

masking tape. Use a long T-bar sander to sand the

top of the wing tip so that it is parallel to the top

surface of the wing. See section A-A on the plans

for clarification.

33. Sheet the top of the wing tip using a

3/32" x 3" x 30" balsa sheet.

34. Build the servo mounts between ribs W6

and W7. Fit and glue the 1/8" x 1/2" x 4" ply

servo rails. Space the rails to fit the servo you will be

using. Sheet the area around the servo using leftover

3 / 3 2 " x 3" so the covering will have a place

to adhere.

15