Dynaflite PT-19 User Manual

Page 11

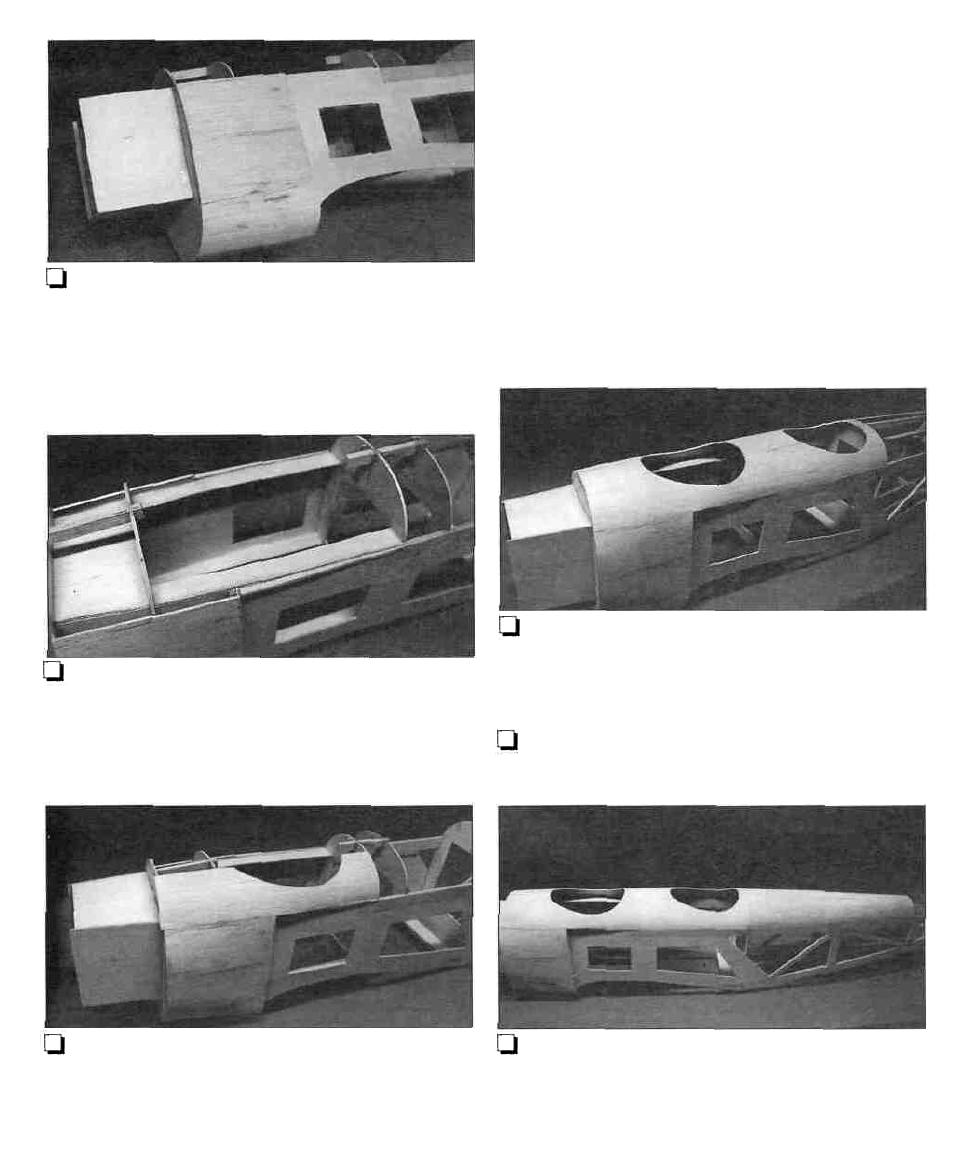

25. Use 1/8" x 3" x 24" balsa to sheet between

bulkheads B and C, from the top deck down. Soak

the outside of the sheeting with water as needed to

get it to bend around the curves. Thin CA works well

on damp balsa.

26. Use a leftover piece of 1/8" x 1/4" balsa

stick to make a filler wedge between bulkheads C

and D. Blend the stick from C to D. This creates a

ledge, to which the top sheeting is glued.

cutting the sheeting to length as the leftover will be

used in the next step. You will have to soak the

sheeting with water to get it to bend properly. A

small amount of ammonia or 50% alcohol added to

the water will help to soften the wood fibers. Be

patient, the best time to do the bending is when the

balsa starts to dry to a damp state. After the side

sheeting strips are glued into position, cut a rough

cockpit opening as shown in the photo. This opening

will relieve some of the stress in the sheeting and

allow it to dry in the proper shape. There is a

pattern for the exact opening in the center of this

manual. Do not glue the center strip until step 29.

—I 28. Sheet between bulkheads D and E using the

leftover 1/8" x 3" balsa sheeting from above, just as

you did in the previous step.

29. Fit and glue the center strip of sheeting.

27. Caution - carefully read and understand this

entire step before proceeding! Use 1/8" x 3" x 24"

balsa to sheet the fuselage top from bulkhead B to .

This will be done with three strips. Be careful when

30. Use 1/8" x 3" x 24" balsa to sheet from

bulkhead E to G. This is a compound curve so go

slowly and be patient. It won't be as hard as it

seems. Just be sure the balsa sheeting is well soaked.

11