Join the wing – Dynaflite GPMA0525 User Manual

Page 16

between the tips of the aileron and the wing. We

recommend a 1/16" gap at both ends.

❏ ❏

11. Cut a groove and drill a 7/64" (or 3/32") hole

in the leading edge of the aileron to accommodate

the aileron torque rod. Test fit the aileron to the wing.

❏ ❏

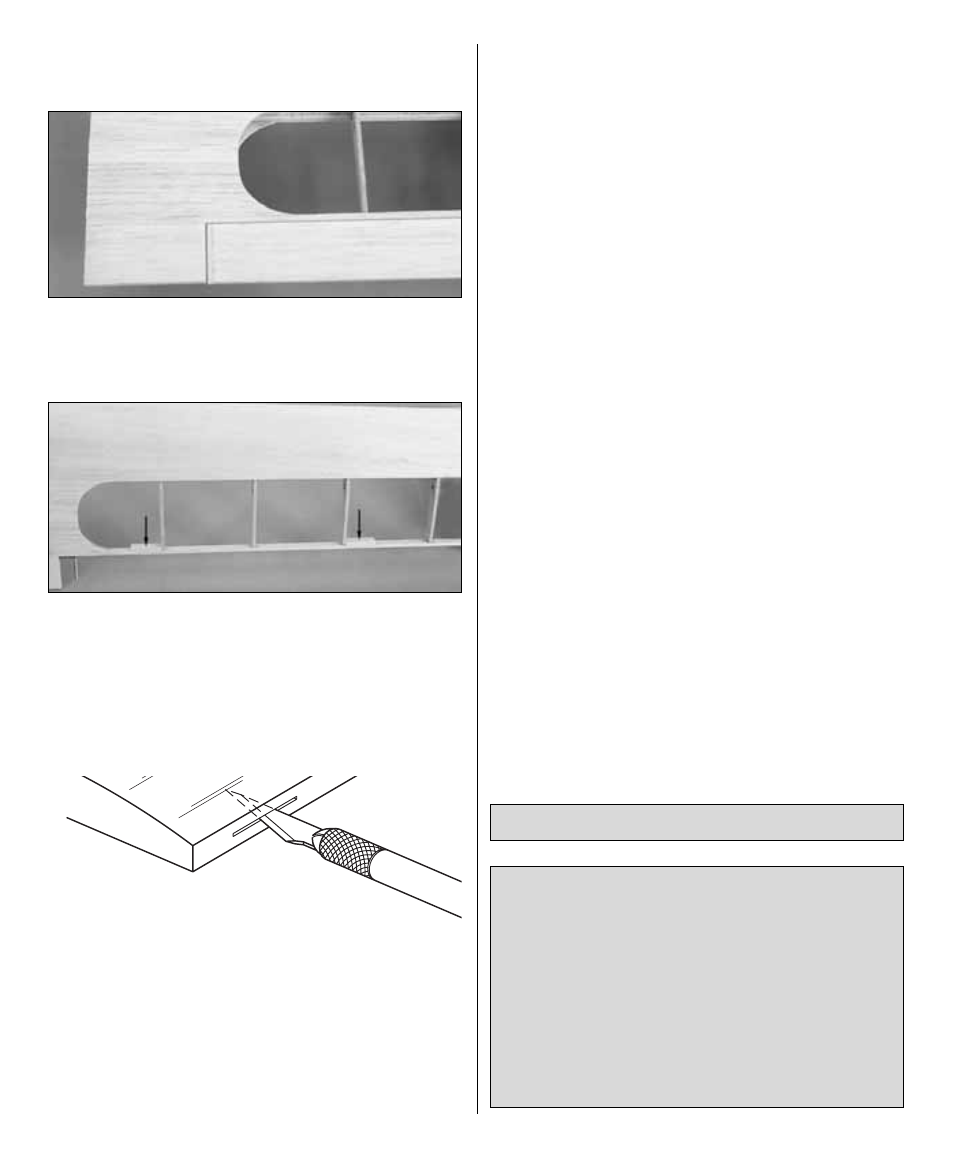

12. Cut three 1/8" x 5/16" x 1" hinge blocks

from leftover 1/8" balsa and glue them to the front

of the sub trailing edge where the hinges are

shown on the plan. The hinge blocks are not

shown on the plan but you can see two of them

in the photo.

❏ ❏

13. Mark the location of the hinges on the wing

and the aileron, then cut the hinge slots with a

#11 blade.

❏ ❏

14. Cut three hinges from the CA hinge strip

and test fit the aileron to the wing with the hinges.

❏ ❏

15. If necessary, shape the TE of the wing tip

and the top of the sub trailing edge to match

the aileron.

❏ ❏

16. Remove the aileron from the wing. Use

a razor plane or a hobby knife followed by a bar

sander with 80-grit sandpaper to shape the

leading edge of the aileron to a “V” to allow for

control movement.

❏ ❏

17. Temporarily join the aileron to the wing.

Operate the aileron by moving the aileron torque

rod back and forth. Make sure you have enough

throw and make sure everything operates

smoothly. Make adjustments as necessary.

That’s about all we can do on this wing until we

join the other wing, so return to step 4 on page

12 and build the Left wing panel. Make sure you

build a LEFT wing panel not a right wing panel!

You may build your wing

flat

or with dihedral.

If you build the wing flat your Talon will have

more maneuverability. If you build your wing

with dihedral your Talon will have more

stability. The wing joiner included with the kit is

for a flat wing. If you wish to build in dihedral,

make your own dihedral brace from 1/8"

plywood (not supplied) using the sketch on

page 24 and raise both tips 3/8" from your

workbench when it’s time to join the wing.

JOIN THE WING

AND #11 BLADE

WITH HOBBY KNIFE

CUT HINGE SLOT

16