Dynaflite GPMA0525 User Manual

Page 15

wing with masking tape until the glue dries

(about an hour should be sufficient).

❏ ❏

4. Use your razor plane followed by a bar

sander with 80-grit sandpaper to blend the LE to

the top and bottom skins. Do not round the LE

until you are instructed to do so after you join the

two halves together.

❏ ❏

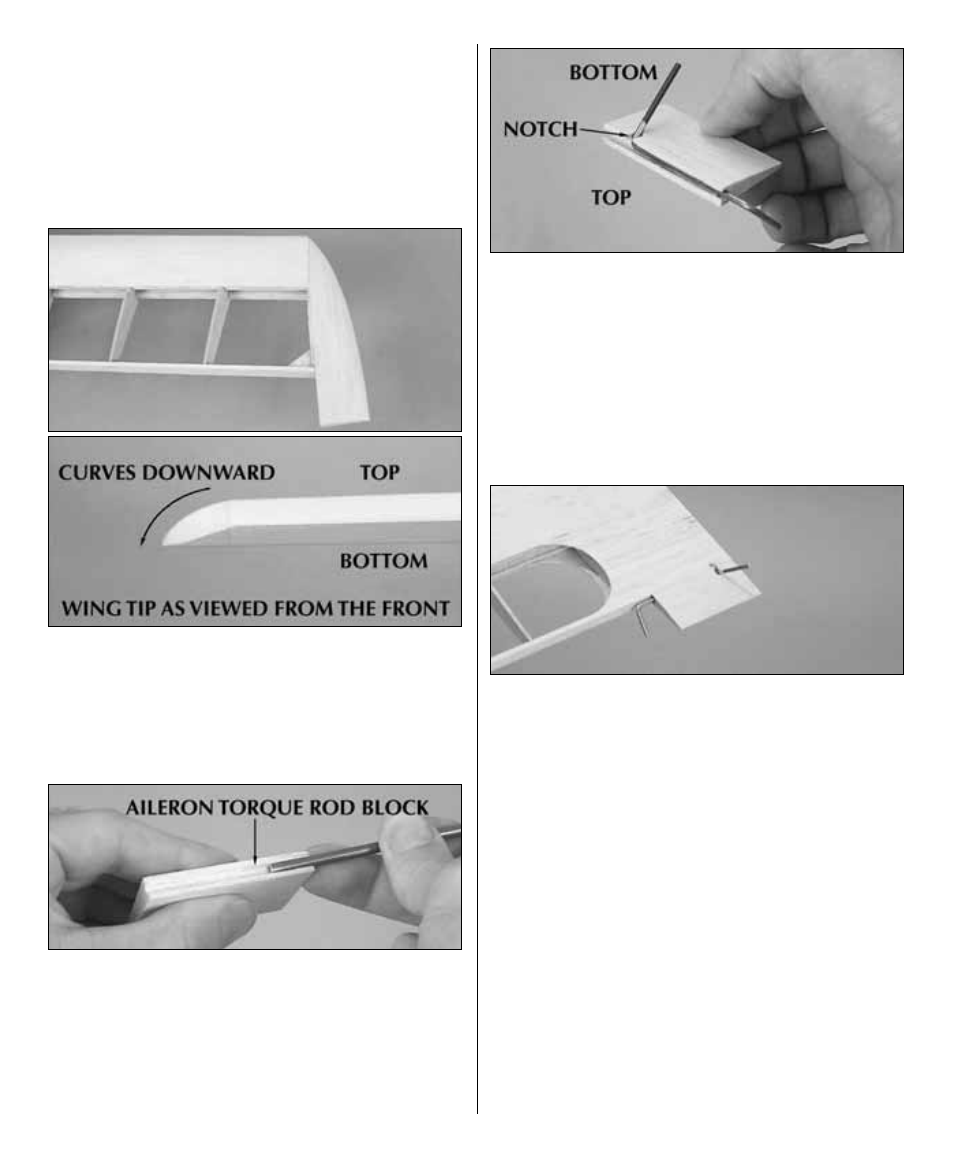

5. Glue a shaped triangular balsa wing tip

block to the end of the wing. Note that the flat

side of the tip block is on the bottom of the wing

so the tip curves downward. Carve, then sand

the wing tip block to match the shape of the wing

and the plan.

❏ ❏

6. Cut 2-1/2" from one of the ailerons you shaped

earlier to make an aileron torque rod block. Cut

a 5/32" groove through the center of the leading

edge of the block to accommodate the nylon

bearing tube on the right aileron torque rod.

Hint: Use a 5/32" brass tube sharpened at one end

to cut the groove.

❏ ❏

7. Test fit the pre-bent wire right aileron

torque rod (or the left aileron torque rod if

this is your second time through and you are

building the left wing panel) in the torque rod

block. If necessary, enlarge the groove you cut so

the torque rod will fit all the way in. Cut a notch in

the bottom of the torque rod block to allow for

control throw.

❏ ❏

8. Cut a notch in the sub trailing edge of the

wing panel (the same as the notch in the torque

rod block) to allow for control throw. Roughen the

nylon bearing tube on the aileron torque rod with

coarse sandpaper. Apply a dab of petroleum jelly

(not marmalade)

to the ends of the bearing tube.

Use thick or medium CA to simultaneously glue

the bearing tube in the torque block and glue the

torque block to the sub trailing edge of the wing.

Note that the bottom of the torque block should

be even with the bottom of the wing.

❏ ❏

9. Use a bar sander with 80-grit sandpaper

to sand the end of the wing square and even.

❏ ❏

10. Trim the tip of the aileron to match the

angle of the wing tip. Test fit the aileron to the

wing. If necessary, glue leftover balsa to the tips

of the aileron to achieve adequate spacing

15