Gas manifold pressure (48 series units only), Unit voltage, Leak test and dehydration – Carrier NP034-074 User Manual

Page 39: Evaporator-fan belts, pulleys, and sheaves

If oil charge is above sight glass, do not remove any oil

until the compressor crankcase heater has been on for at least

24 hours. When additional oil or a complete charge is needed,

use only Carrier-approved compressor oil.

Approved oils:

Texaco, Inc. ................................................. Capella WF-32

Shrieve Chemical Co. ....................... Zerol 150 (Synthetic)

Witco Co. .......................................................... Suniso 3GS

Do not reuse drained oil and do not use any oil that has

been exposed to the atmosphere.

Gas Manifold Pressure (48 Series Units Only)

—

Check pressure to ensure it matches the pressure stamped

on the valve body. See Gas Valve Adjustment section on

page 50 for more details.

Unit Voltage —

Be sure power source agrees with the

unit nameplate rating.

Leak Test and Dehydration —

Be sure there are no

refrigerant leaks. All units are shipped with a complete op-

erating charge of R-22 (Tables 1A and 1B) and should be

under sufficient pressure for leak testing after installation. If

there is no system pressure, add refrigerant until a pressure

is observed and then check for leaks. After leaks are re-

paired, remove and recover refrigerant from the system. For

leak testing procedures, see Carrier Standard Service Tech-

niques, Refrigerants section. Do not use the system com-

pressors to remove refrigerant from the system.

Evaporator-Fan Belts, Pulleys, and Sheaves —

Belts, pulleys, and sheaves are factory installed. All pulleys

are nonadjustable.

See Tables 1A and 1B for fan shaft center distance ranges

and shaft sizes when making selections for field-supplied drives.

See Tables 9A and 9B for a complete listing of field-

supplied pulleys and belt connections.

Check the lubrication of fan and motor bearings. Bearings

are shipped full of grease for corrosion protection and may

run warm temporarily on start-up until the excess grease has

discharged. Check bearing setscrews for tightness. Also check

the tightness of the setscrews on the fan wheel and on the

fan and motor sheaves. Check fan shaft bearing mountings

for tightness.

Recheck sheave alignment and belt tension. See Adjust-

ments section on page 46 for instructions.

Hand-turn the fan to make sure the fan wheel does not rub

on the fan housing. The fan shaft and motor shaft must be

free wheeling before power is applied to the unit.

Following the necessary electrical checks, check for fan

vibration. If excessive vibration occurs, check for:

• drive misalignment

• mismatched belts

• wheel or sheaves loose on shaft

• loose bearings

• loose mounting bolts

• motor out of balance

• sheaves eccentric or out of balance

• wheel out of balance (replace if necessary)

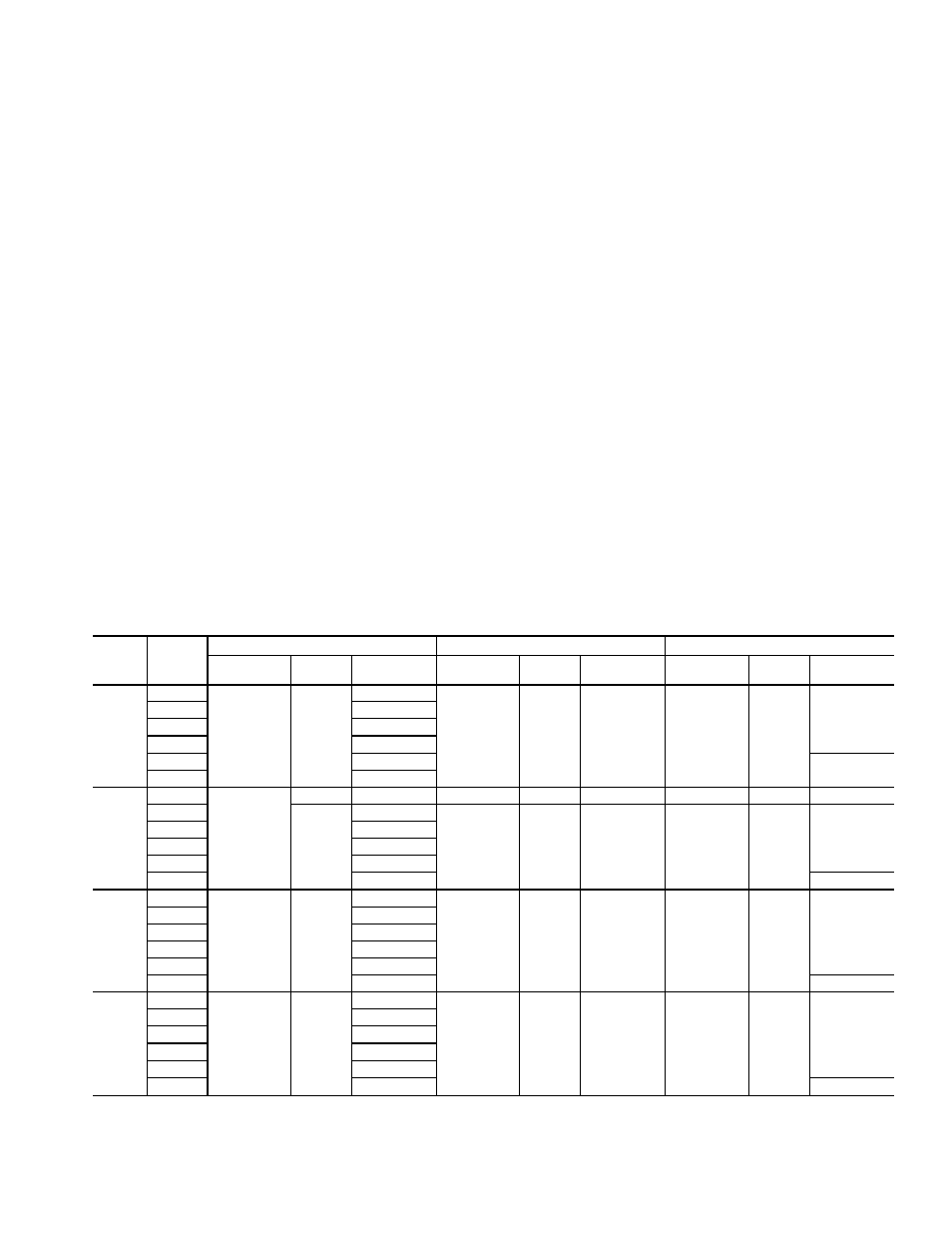

Table 9A — Field-Supplied Evaporator-Fan Pulley Data, 034,044 Units

IFM

Hp

IFM

RPM

MOTOR PULLEY

BLOWER PULLEY

BELTS

No.

Grooves

Type

Size (in.)

No.

Grooves

Type

Size (in.)

Quantity

Type

Size (in.)

7

1

⁄

2

435

2

BK

3.4

2

B5V

13.6

2

BX

61.8

500

3.9

590

4.6

650

5.1

720

5.6

64.8

820

6.4

10

500

2

BK

3.9

2

B5V

13.6

2

BX

61.8

550

B5V

4.3

2

B5V

13.7

2

5VX

63.0

575

4.5

650

5.1

730

5.7

830

6.5

66.0

15

550

2

B5V

4.3

2

B5V

13.7

2

5VX

63.0

625

4.9

675

5.3

730

5.7

800

6.3

880

6.7

66.0

20

575

2

B5V

4.5

2

B5V

13.7

2

5VX

63.0

625

4.9

700

5.5

750

5.5

830

6.5

880

6.9

66.0

IFM — Indoor (Evaporator) Fan Motor

39