Warning – Crosman 1720T User Manual

Page 4

4

B. Unloading Pellets

• The most common way to unload a pellet is to fire your airgun in a SAFE DIRECTION following section

5 on Aiming and Firing Safely. If a pellet has become lodged in the barrel follow the steps in section 6

Removing a Jammed Pellet.

C. Un-cocking

• To uncock the action, take the airgun “OFF SAFE.” With the muzzle pointed in a SAFE DIRECTION, open

the bolt and pull all the way to the rear. Holding the bolt handle securely, pull the trigger with your other

hand and slowly ease the bolt as far forward as it will go with your hand. You may now lower the bolt and

the airgun is un-cocked.

• Put the airgun “ON SAFE”.

5. Aiming and Firing Safely

• Always point your airgun in a SAFE DIRECTION.

• Follow the instructions for filling the air gun (section 3) and loading pellets (section 4A).

• You and others with you should always wear shooting glasses to protect your eyes.

• Do not shoot at hard surfaces or at the surface of water. The pellet may bounce off or ricochet and hit

someone or something you had not intended to hit.

• Always choose your target carefully. It is best to shoot at paper bull’s-eye targets attached to a safe

backstop. A heavy blanket should be hung behind the backstop to prevent ricochet should you miss the

backstop.

• Your airgun is designed for target shooting and is suited for both indoor and outdoor use. Always remem-

ber to place your target carefully. THINK about what you will hit if you miss the target.

• Before firing the airgun make certain there is sufficient pressure for proper operation.

6. Removing a Jammed Pellet

A jammed pellet is usually the result of trying to fire the airgun when the pressure is too low. Before firing the

airgun make certain there is sufficient pressure for proper operation, by making sure the gauge needle is

pointing to the area between 1000 and 3000 psi.

WARNING:

In this procedure you will put a cleaning rod down the barrel of a charged airgun. It is

extremely important that while you are doing this the airgun be “ON SAFE”, the bolt remains in open

position and that your finger be kept away from the trigger. Failure to follow this warning may result in

serious injury or death.

• Point the airgun in a SAFE DIRECTION.

• Put the airgun “ON SAFE” (see section 2A.)

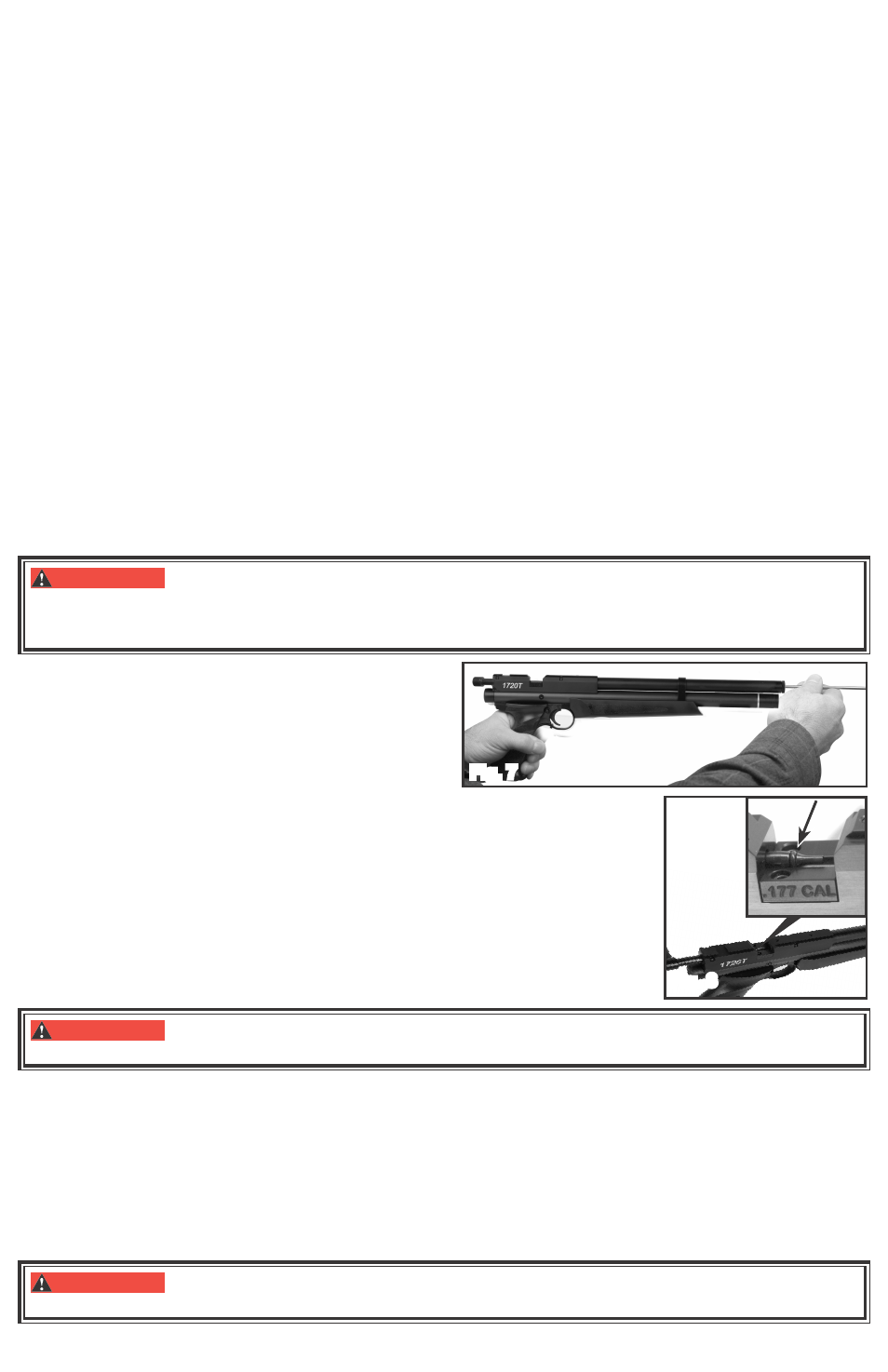

• Open the bolt by pushing the bolt handle up and

pulling it all the way back.

• With the bolt in the rearward position insert a

ramrod of the proper size into the barrel (start at the

muzzle). (fig. 6) The barrel could be damaged if the

proper sized cleaning rod is not used.

Note: The bolt must be cocked and open for the jammed pellet to clear the

breech when it is pushed out by the ram rod.

• Using the ramrod push the pellet into the pellet loading port (forward of the

bolt), remove and discard the pellet. Do not reuse that pellet.

• Point the airgun in a SAFE DIRECTION. Close the action take “OFF SAFE” and fire.

• Put the airgun “ON SAFE” (see section 2A.)

• If you are not able to unjam your airgun by following this procedure, take no

further action. Crosman Corporation or an Authorized Service Station will

unjam your airgun. (no cost during the warranty period)

7. Maintaining Your Airgun

WARNING:

Use of petroleum-based lubricants in the pressure reservoir could result in an explo-

sion resulting in personal injury.

• Keep all petroleum-based lubricants away from the fill nipple. They MUST NOT be introduced into the high

pressure reservoir.

• Apply Crosman silicone chamber oil (part number RMCOIL) on the bolt o-ring every 3 months or 500

shots (fig. 7)

• Apply a moly graphite EP (Extreme Pressure) grease to the sliding bolt mechanism every 3 months or 500 shots.

DO NOT MODIFY OR ALTER YOUR AIRGUN. Attempts to modify the airgun in any way inconsistent with

this manual may make your airgun unsafe to use, cause serious injury or death, and will void the warranty.

If you drop your airgun, visually check to see that it works properly before you use it again. If anything seems

changed, like a shorter or weaker trigger pull, this may mean worn out or broken parts. Call Crosman cus-

tomer service for assistance before using your airgun again.

WARNING:

Do not attempt to repair the airgun or to disassemble to correct an over fill or valve

lock. Parts can fly from the airgun at dangerous speeds when it is disassembled while pressurized.

Fig. 7

Fig. 8