Troubleshooting, 50h e, h j – Carrier 50HE003-006 User Manual

Page 67

67

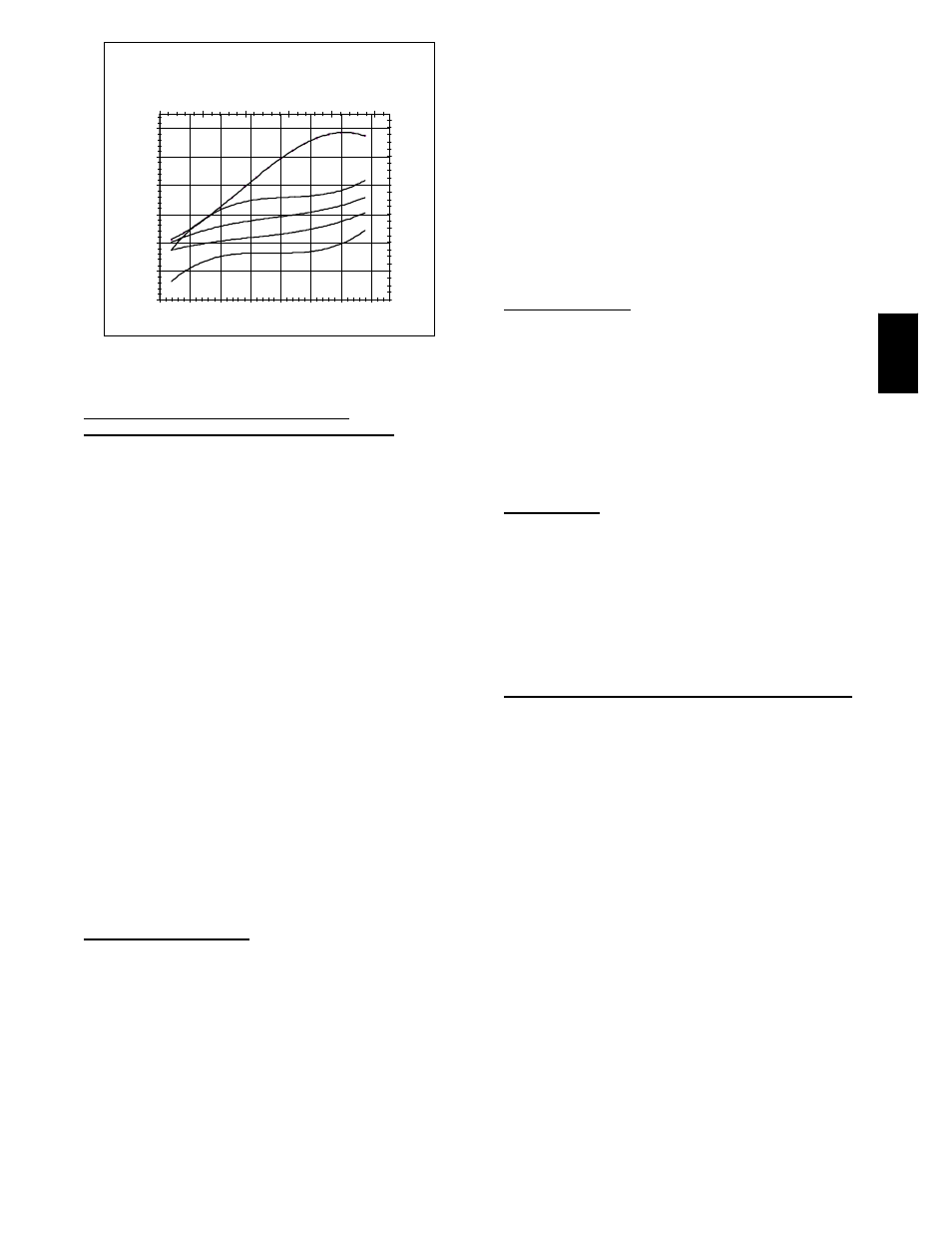

50HE -- 5 TON CHARGING CHART

55.0

65.0

75.0

85.0

95.0

105.0

115.0

42

47

52

57

62

67

72

77

Suction Line Temp (deg F)

S

ucti

on

Li

ne

P

ressu

re

(p

si

g)

310.0

410.0

510.0

610.0

710.0

810.0

0.0

5.0

10.0

15.0

20.0

25.0

Suction Line Temperature (deg C)

S

ucti

on

Li

ne

P

ressu

re

(kp

a)

F

C

115

46

105

41

95

35

85

29

75

24

C06151

Fig. 69

--- Cooling Charging Chart,

Standard 50HE006

To Use Cooling Charging Charts, Units With

Humidi--Mizer™ Adaptive Dehumidification System

Refer to charts (Fig. 62-65) to determine the proper leaving

condenser pressure and temperature.

Example (Fig. 62):

Leaving Condenser Pressure

250 psig

. . . . . . . . . . . . . . . . .

Leaving Condenser Temperature

105_F

. . . . . . . . . . . . . . .

NOTE: When using the charging charts, it is important that only

the subcooling/reheat dehumidification coil liquid line solenoid

valve be energized. The subcooling/reheat dehumidification coil

liquid line solenoid valve MUST be energized to use the charging

charts and the outdoor motor speed controller jumpered to run the

fan at full speed.

IMPORTANT: Refer to Troubleshooting Tables for additional

information.

Step 6

—Replacement Parts

A complete list of replacement parts may be obtained from any

Carrier distributor upon request.

TROUBLESHOOTING

Step 1

—Unit Troubleshooting

Refer to Tables 34-38 for unit troubleshooting details.

Step 2

—Economi$er IV Troubleshooting

See Table 39 for EconoMi$er IV logic.

A functional view of the EconoMi$er IV is shown in Fig. 67.

Typical settings, sensor ranges, and jumper positions are also

shown. An EconoMi$er IV simulator program is available from

Carrier

to

help

with

EconoMi$er

IV

training

and

troubleshooting.

Economi$er IV Preparation

This procedure is used to prepare the EconoMi$er IV for

troubleshooting. No troubleshooting or testing is done by

performing the following procedure.

NOTE: This procedure requires a 9-v battery, 1.2 kilo-ohm

resistor, and a 5.6 kilo-ohm resistor which are not supplied with

the EconoMi$er IV.

IMPORTANT: Be sure to record the positions of all

potentiometers before starting troubleshooting.

1. Disconnect power at TR and TR1. All LEDs should be

off. Exhaust fan contacts should be open.

2. Disconnect device at P and P1.

3. Jumper P to P1.

4. Disconnect wires at T and T1. Place 5.6 kilo-ohm resistor

across T and T1.

5. Jumper TR to 1.

6. Jumper TR to N.

7. If connected, remove sensor from terminals S

O

and +.

Connect 1.2 kilo-ohm 4074EJM checkout resistor across

terminals S

O

and +.

8. Put 620-ohm resistor across terminals S

R

and +.

9. Set minimum position, DCV set point, and exhaust

potentiometers fully CCW (counterclockwise).

10. Set DCV maximum position potentiometer fully CW

(clockwise).

11. Set enthalpy potentiometer to D.

12. Apply power (24 vac) to terminals TR and TR1.

Differential Enthalpy

To check differential enthalpy:

1. Make sure EconoMi$er IV preparation procedure has been

performed.

2. Place 620-ohm resistor across S

O

and +.

3. Place 1.2 kilo-ohm resistor across S

R

and +. The Free

Cool LED should be lit.

4. Remove 620-ohm resistor across S

O

and +. The Free Cool

LED should turn off.

5. Return EconoMi$er IV settings and wiring to normal

after completing troubleshooting.

Single Enthalpy

To check single enthalpy:

1. Make sure EconoMi$er IV preparation procedure has been

performed.

2. Set the enthalpy potentiometer to A (fully CCW). The

Free Cool LED should be lit.

3. Set the enthalpy potentiometer to D (fully CW). The Free

Cool LED should turn off.

4. Return EconoMi$er IV settings and wiring to normal

after completing troubleshooting.

DCV (Demand Controlled Ventilation) and Power Exhaust

To check DCV and Power Exhaust:

1. Make sure EconoMi$er IV preparation procedure has been

performed.

2. Ensure terminals AQ and AQ1 are open. The LED for

both DCV and Exhaust should be off. The actuator should

be fully closed.

3. Connect a 9-v battery to AQ (positive node) and AQ1

(negative node). The LED for both DCV and Exhaust

should turn on. The actuator should drive to between 90

and 95% open.

4. Turn the Exhaust potentiometer CW until the Exhaust

LED turns off. The LED should turn off when the

potentiometer is approximately 90%. The actuator should

remain in position.

5. Turn the DCV set point potentiometer CW until the DCV

LED turns off. The DCV LED should turn off when the

potentiometer is approximately 9 v. The actuator should

drive fully closed.

6. Turn the DCV and Exhaust potentiometers CCW until the

Exhaust LED turns on. The exhaust contacts will close 30

to 120 seconds after the Exhaust LED turns on.

7. Return EconoMi$er IV settings and wiring to normal

after completing troubleshooting.

50H

E,

H

J