50h e, h j – Carrier 50HE003-006 User Manual

Page 41

41

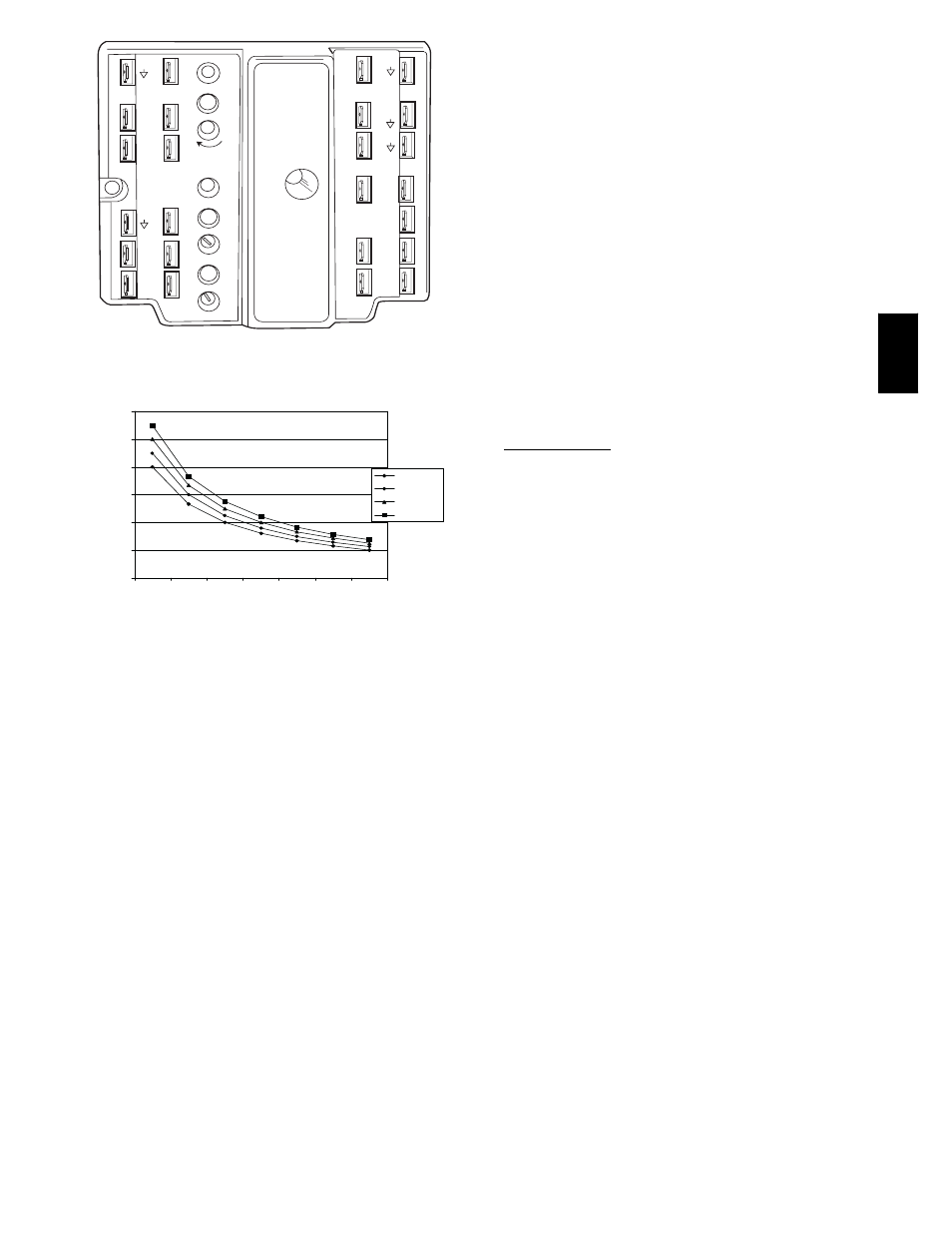

TR1

24 Vac

COM

TR

24

Vac

HOT

1

2

3

4

5

EF

EF1

+

_

P1

T1

P

T

N

EXH

2V

10V

EXH

Set

Set

2V

10V

2V

10V

DCV

DCV

Free

Cool

B

C

A

D

SO+

SR+

SR

SO

AQ1

AQ

DCV

Min

Pos

Open

Max

N1

C06038

Fig. 44

--- EconoMi$er IV Control

0

1000

2000

3000

4000

5000

6000

2

3

4

5

6

7

8

800 ppm

900 ppm

1000 ppm

1100 ppm

RANGE

CONFIGURA

TION

(ppm)

DAMPER VOLTAGE FOR MAX VENTILATION RATE

CO SENSOR MAX RANGE SETTING

2

C06039

Fig. 45

--- CO

2

Sensor Maximum Range Setting

CO

2

Sensor Configuration

The CO

2

sensor has preset standard voltage settings that can be

selected anytime after the sensor is powered up. (See Table 8.)

Use setting 1 or 2 for Carrier equipment. (See Table 8.)

1. Press Clear and Mode buttons. Hold at least 5 seconds

until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to select the preset number. (See

Table 8.)

4. Press Enter to lock in the selection.

5. Press Mode to exit and resume normal operation.

The custom settings of the CO

2

sensor can be changed anytime

after the sensor is energized. Follow the steps below to change the

non-standard settings:

1. Press Clear and Mode buttons. Hold at least 5 seconds

until the sensor enters the Edit mode.

2. Press Mode twice. The STDSET Menu will appear.

3. Use the Up/Down button to toggle to the NONSTD menu

and press Enter.

4. Use the Up/Down button to toggle through each of the

nine variables, starting with Altitude, until the desired

setting is reached.

5. Press Mode to move through the variables.

6. Press Enter to lock in the selection, then press Mode to

continue to the next variable.

Dehumidification of Fresh Air with DCV Control

Information from ASHRAE indicates that the largest humidity

load on any zone is the fresh air introduced. For some

applications, a device such as a 62AQ energy recovery unit is

added to reduce the moisture content of the fresh air being

brought into the building when the enthalpy is high. In most

cases, the normal heating and cooling processes are more than

adequate to remove the humidity loads for most commercial

applications.

If normal rooftop heating and cooling operation is not adequate

for the outdoor humidity level, an energy recovery unit and/or a

dehumidification option should be considered.

Step 7

—Adjust Evaporator--Fan Speed

Adjust evaporator-fan speed to meet jobsite conditions.

Tables 9 and 10 show fan rpm at motor pulley settings for the

50HE003--006 and 50HJ004--007 units. Tables 11 and 14 show

maximum amp draw of belt-drive motor. Table 13 shows sound

data. Refer to Tables 15-34 for performance data. See Table 35

for accessory static pressure drop. See Fig. 47 for the

Humidi-MiZer™ system static pressure drops.

For units with electric heating, required minimum cfm is 900 for

50HJ004; 1200 for 50HJ005; 1500 for 50HJ006 and 1800 for

50HJ007.

Belt Drive Motors

Fan motor pulleys are factory set for speed shown in Table 1.

Check pulley alignment and belt tension prior to start-up.

To change fan speed:

1. Shut off the unit power supply and tag disconnect.

2. Loosen the belt by loosening the fan motor mounting nuts.

(See Fig. 47.)

3. Loosen movable pulley flange setscrew (See Fig. 48).

4. Screw movable flange toward fixed flange to increase

speed and away from fixed flange to decrease speed.

Increasing fan speed increases load on motor. Do not

exceed maximum speed specified in Table 1.

5. Set movable flange at nearest keyway of pulley hub and

tighten setscrew. (See Table 1 for speed change for each

full turn of pulley flange.)

6. Adjust belt tension and align fan and motor pulleys per

guidance below.

NOTE: Once the required flange position is determined for the

correct blower rpm, it is recommended (but not required) that the

variable pitch pulley be replaced with a corresponding size fixed

sheave pulley.

To align fan and motor pulleys:

1. Loosen fan pulley setscrews.

2. Slide fan pulley along fan shaft.

3. Make angular alignment by loosening motor from mount-

ing.

To adjust belt tension:

1. Loosen fan motor mounting nuts.

2. Slide motor mounting plate away from fan scroll for

proper belt tension (

1

/

2

-in. deflection with 7 to 10 lb of

force).

3. Tighten motor mounting nuts.

4. Adjust bolt and tighten nut to secure motor in fixed

position.

50H

E,

H

J