Fluid shutoff valve, Repairing hydra-spray hose – Graco 226-167 SERIES"A" User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

'

2. Remove oiler from a±r motor top cap. See

?ig. 5. Fill oiler vdth kerosene. Replace oiler.

3

. Allow a soaking period of 5 to 10 minutes,

then start air motor. Run motor slowly. After

smooth operation has been achieved and kerosene has

been hlown from exhaust, stop motor, remove oiler

screw and fill oiler with a light air motor oil.

NOTE: MASK N0 ATTEMPT TO DISASSEMBLE AIR

MOTCR. If it should need repair, contact your

nearest Grace Authorized Service Depot.

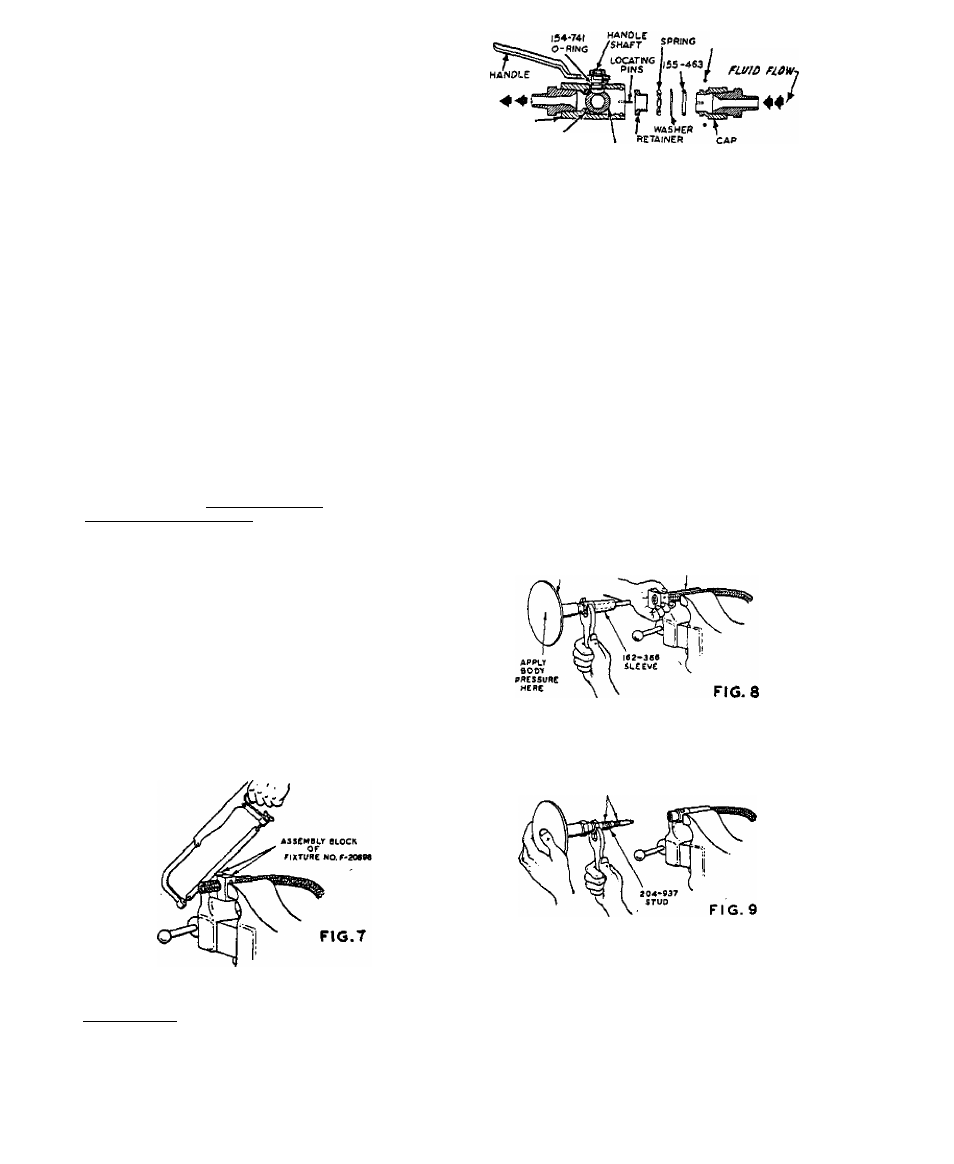

FLUID SHUTOFF VALVE

205-583 iACCESSORY)

ORIVf PfNS

BOOY-

562-833 SEAT

I62-B34 BALL

FIG.6

ELEVATOR

LDBRICATION

Worn ”CF* rings, ball seat or ball may cause

valve to fail to operate. If service is necessary,

shut off air supply, relieve fluid pressure and re

move valve. Place valve body in a vise and drive

the two pins out of holes in valve body. Remorve

valve cap firom body being careful not to turn cap

as this would shear off the locating pins in valve

body. See Fig. 6. Disassemble and replace any

worn or damaged parts. NOTE; With handle removed,

nO”

ring

15L-741

can be beat removed by first re

moving ball 162-83L from body and then pushing

handle shaft down Into cavity in valve body.

Every 2 to 6 weeks with elevator free of air

pressure, unscrew and remove cap l6iii-2ii.6. Fill

inner cavity of cup leather 150-179 'with SAE 20

oil. Replace cap. Raise elevator and lubricate

exposed surface of elevator guide tube I6i4.-2L7.

See parts illustration for location of parts.

PUMP. REGULATOR, SPRAY GUN AND

FILTER OR SURGE CHAMBER

Refer to separate sheet for maintenance in-

■ structions and parts identification.

REPAIRING HYDRA-SPRAY HOSE

Hvdra-Spray hose is constructed of Dupont

"PTFE^ inner lining tube with stainless steel

wire oraid outer cover. This hose is expensive

and should be handled with care. If hose should

become damaged it can be salvaged by assembling

couplings to the broken ends of hose sections.

Graco detachable and reusable couplings consist

of two parts, the female swivel stud 20Д.-937 and '

the sleeve 162-366, and are assembled upon hose

in the following manner;

MOTE: A hose coupling fixture Graco No.

F-20898 specifically designed to facilitate the

assembly of couplings upon this type of hose may

be obtained from factory. This fixture consists

of a two piece assembly block and an assembly

tool as shown in Fig. 7,

S

and 9.

_

1. Position the two piece assembly block on

hose with plain side of block toward hose end to

be cut and clamp in a vise as shown in Pig. 7.

Cut off with a fine tooth hand hack saw.

2. Remove hose from block and grip in vise

about 2 inches from end just cut. CAUTION; Do

not crush the hose—apply only enough pressure

on the vise jaws to hold while forcing the sleeve

onto hose.

3

. Add a drop of oil to the end of the

wires, position assembly block with its grooved

side toward end of hose just cut and slide block

onto hose until it protrudes about 1/32 to

I/I

6

of an inch beyond the end of hose. See Fig. 8.

ASSEMlLf TOOL

OF FiXTUHL

CAUTION-

DO NOT CRUSH

H05C

if. sup

the threaded end of sleeve

162-366

over assembly tool as shown In Fig. 8 and while

holding block in place on hose, insert end of tool

into hose and end of sleeve into groove.

OIL LIOHT

l

T

5* While twisting sleeve back and forth

with a wrench apply body pressure to assembly

tool and as sleeve is forced onto hose allow

block to slide back. After about

i

inch of

hose is covered, remove the block and continue

to force sleeve onto the hose until end of hose

reaches the shoulder in sleeve. Refer to

Fig. 10.