Operation – Graco 226-167 SERIES"A" User Manual

Page 5

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

5.

Remove from base the 10 gallon pail pro

vided. Wipe clean its interior and potiT into it

material stirred and thinned to the proper spray-

consistency or place a smaller container of ma

terial inside the 10 gallon pail. Stir material

thoroughly making sure there is no heavy pigment

concentration or cake formed on the bottom of the

container* The pigments must be well dispersed to

prevent them from clogging the fluid intake

strainer 205-306 v4ien the pump is initially lower

ed into the container of material.

ROTBs For a small container, such as a one

gallon can, the material intake strainer must be

removed in order to get the lower pump housing and

the agitator propeller into the container.

6.

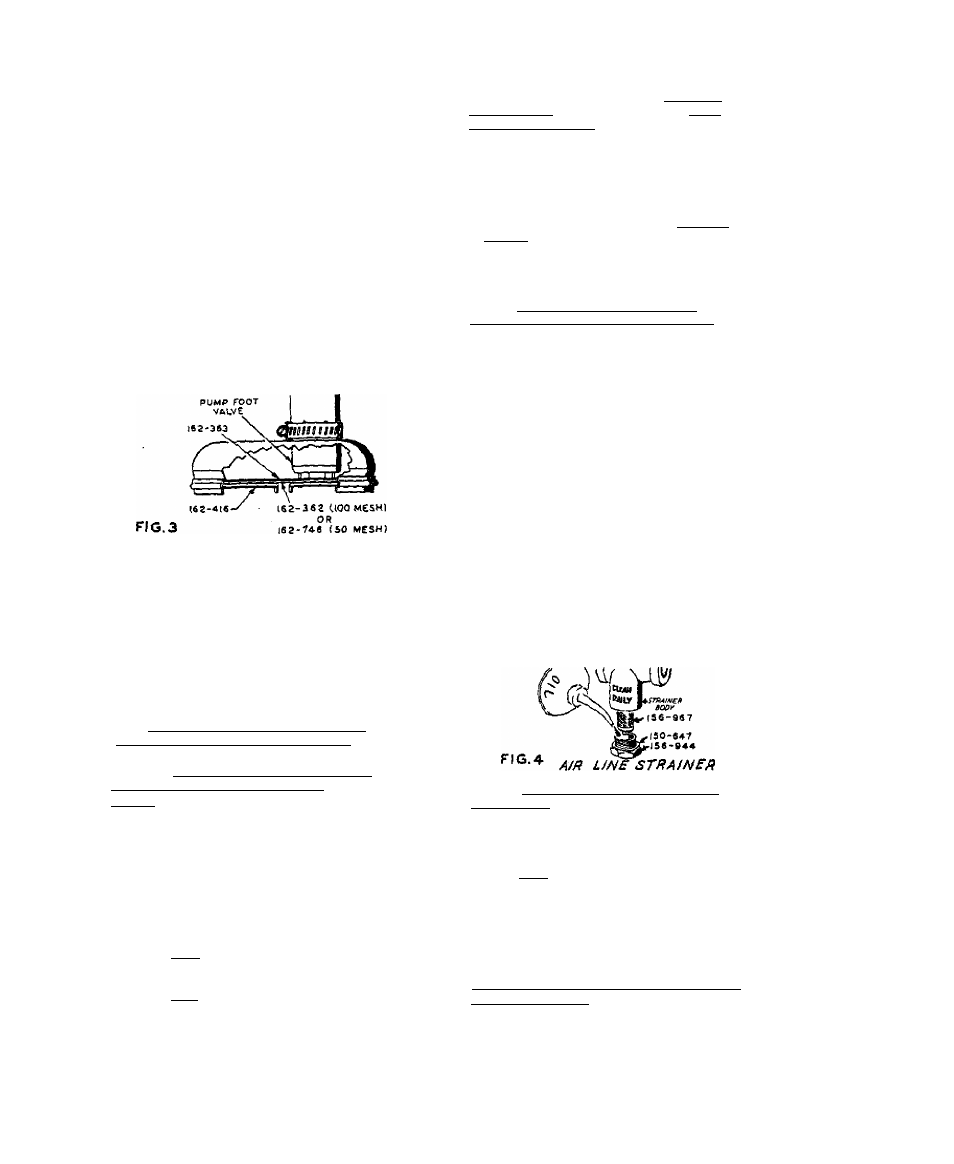

Check the position of foot valve feet in

relation to the perforated plate 162-363 of pump

fluid intake strainer. When the plate and screen

are held in position by the retaining ring 162-416,

the feet of foot valve body must contact and sup

port the perforated plate 162-363 as shown in

Fig. 3*

NOTE: If desired, the 100 mesh screen in

strainer 205-306 can be removed and replaced -with

the extra, more coarse 50 mesh screen 162-746 sup

plied. Refer to Fig. 3- This 50 mesh screen

should be used with spray tips having larger ori

fice openings.

7* Lower pump into material. If unit with

manual elevator, unhook hanger to lower. If unit

with pneumatle elevator, lower by disconnecting

air hose 160-023 from elevator air line fitting*

Refer to Fig. 1*

NOTE; The speed at which unit is elevated^

bv air, is set at factory. If adjustment is

necessary, loosen lock nut of air restrictor

valve 203-743 and turn restrictor screw clockwise

to decrease or cqunterolo^kwi^e to increase * Lock

screw in place with lock nut when adjustment is

completed. Air.restrictor valve 203-743 is locat

ed atop elevator tube. Refer to Fig. 1.

8,

If unit includes a filter kit 205-523 or

a filter kit 205-523 and a surge taniT 205-4767

refer to illustrated instructions in separate

Form

306-696

for easy conversion of manifold

205-485 to a filter or a filter-surge chaaiber. .

9- Insert delivery end of material dispens

ing hose into a xiraste container. Start pump by

opening CM-OFF punro air petcock 202-338 and set

ting regulator

205-360

at 30 p.s.i. Refer Fig. I.

Allow pimip to operate until all traces of rust

inhibiting oil, with vrfiich pump was treated, is

removed. Stop pump and discard material pumped.

NOTE: If accessories have been added to

-unit for two gun operation, open material shutoff

valves 205-583 and insert ends of both hoses Into

-waste container before starting pump. Refer to

Fig. 2.

10. Connect swivel 204-940, at-tached to free

end of material dispensing hose, to spray gun

inlet.

OPERATION

IMPORTANT NOTES

1.

For most satisfactory operating condi

tions, locate pump and material so that they will

not be subjected to temperatures below 65° F.

2.

Do no.t attempt to spray materials con

taining hea-gy fillers, dirt or other coarse

particles> Coarse grind, coagulated, con-taminat-

ed and skinned materials that will not pass freely

through the openings in sice

of

screen or filters

being used, without clogging, can not be satis

factorily sprayed. Due to the extremely small

orifice diameter in spray tip through vdiich ma

terial must be forced under pressure, it is very

Impor-bant that particle's which could plug this

orifice are not present in the material to be

sprayed.

3

.

Daily, before starting to spray, remove

and clean filter, if used, of spray gun.

Paily. with air pressure shut off and

relieved, remove and clean screen in air line

s-fcrainer 204-999 (accessory), if used. Add

light oil to screen cavity in strainer nut. See

Fig. 4.

5

.. Dally or more often if experience indi

cates necessary. WITH PUMP DEACTIVATED AMD FILTER

DUMP

VALVE OPEN TO RELIEVE MATERIAL PRESSURE, re

move and clean filter cartridge or screen, if

used. Refer to Fig. 1.

6

. Dally, remove and clean screen in pump

material intake strainer 205-306. When replacing,

check to be sure that plate

162-363

is in contact

with feet of pwmp foot -valve. Refer to Fig.

3

7* When thinning material;cleaning filters,

screen, tips, etc.; changing types of material to

be sprayed or flushing unit; be sure to tise CLEAN

solvent of a type recommended b.y manufacturer of

material being sprayed. Use of the wrong solvent

may cause jelling or separation, of material oompo-

ents which could cause clogging of strainer,

filter and spray gun tip. DO NOT USE COMMON GUN

CLEANER.