Warning, General troubleshooting, Spray pattern troubleshooting – Graco HIGH EFFICIENCY LOW PRESSURE AA2000 User Manual

Page 11: Troubleshooting

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Troubleshooting

WARNING

To reduce the risk of serious injury, including fluid injection, splashing fluid or solvent in the eyes or on the

skin, or injury from moving parts, always follow the

Pressure Relief Procedure Warning

on page 10 when

ever you shut off the pump, when checking or servicing any part of the spray system, when installing, clean

ing or changing spray tips, and whenever you stop spraying.

NOTE: Check all possible remedies in the Troubleshooting Charts before disassembling the gun.

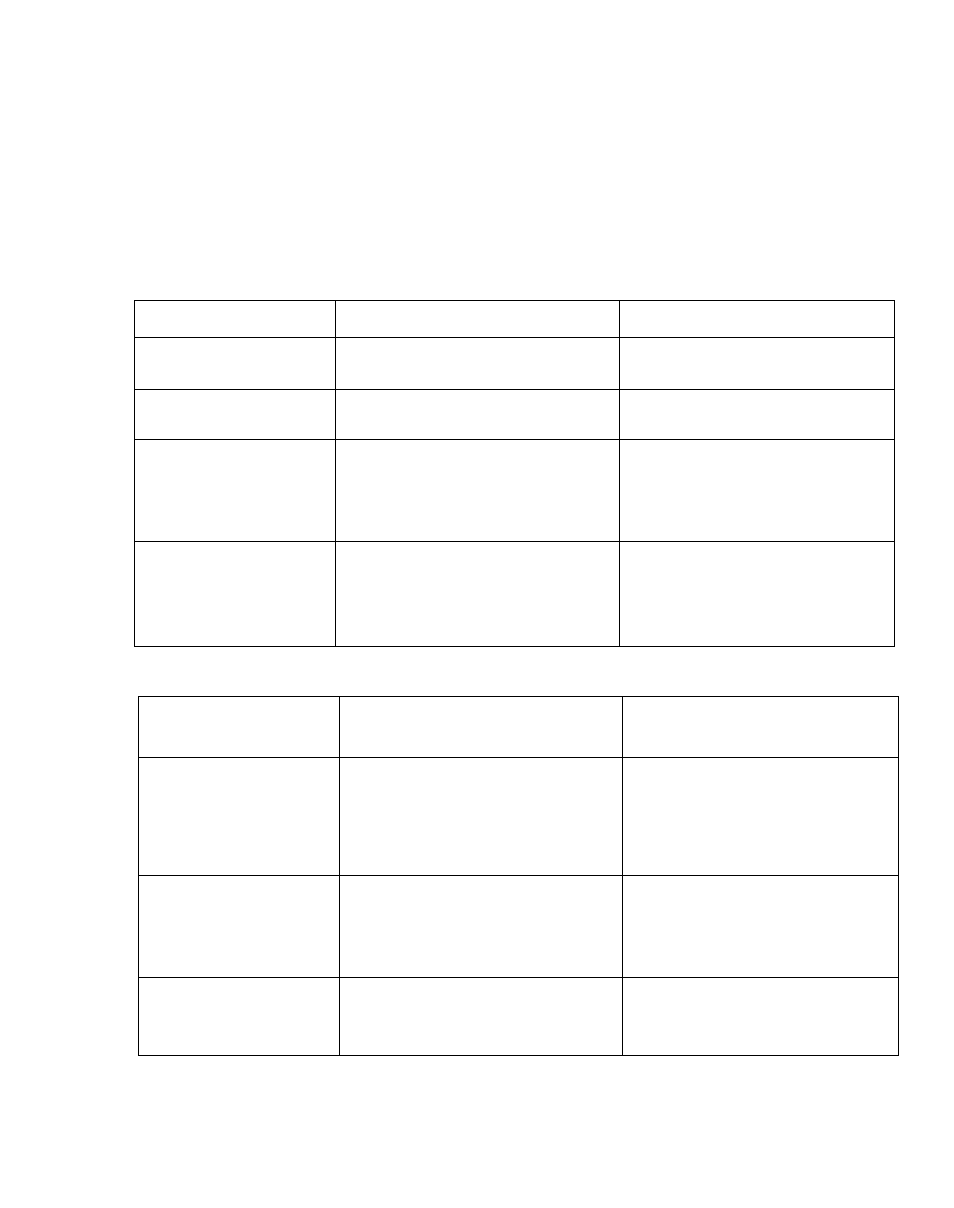

General Troubleshooting

PROBLEM:

CAUSE

SOLUTION

Fluid leakage from back

of fluid needle

Worn packings or needle shaft.

Replace packings (47) or

needle (5). See page 12.

Air leakage from front

of gun

Air valve (52) not seating properly.

Clean, service. See page 12.

Fluid leakage from front

of gun.

Needle worn or damaged.

Replace fluid needle (5).

See page 12.

Worn diffuser housing.

Replace diffuser housing (30).

See page 12.

Fluid in air passages from

air holes in cap.

Fluid tip seal leaking.

Tighten or replace tip (28).

Fluid iniet fitting ieaking.

Replace gasket (33). The gasket (33)

must be replaced if the fluid fitting

(67) is removed.

Spray Pattern Troubleshooting

PROBLEM:

IMPROPER SPRAY

PATTERN

CAUSE

SOLUTION

Fluttering or spitting spray

Insufficient fluid supply.

Adjust fluid regulator or fill fluid

supply tank.

>

Air in paint supply line.

Check, tighten siphon hose

connections, bleed air from

paint line.

Irregular pattern

Fluid build-up or spray tip

partially plugged.

Clean spray tip. See page 10.

On defective side of pattern, air horn

holes are partially or totally plugged.

Clean air horn holes with solvent

and soft brush. See page 10.

Pattern pushed to one side,

same side of air cap gets

dirty.

Air horn holes partially or totally

plugged.

Clean air horn holes with solvent

and soft brush. See page 10.

NOTE: Some improper patterns are caused by the improper balance between air and fluid.

307-947

11