Cleaning & maintenance, Perform a leak test, Cleaning venturi tubes – Kenmore 16238 User Manual

Page 27

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CLEANING & MAINTENANCE

To keep your grill working at its peak efficiency as well as

contribute to the safe operation of this unit, perform all of the

operations below at least once a year -- preferably at the start of

each cooking season.

PERFORM A LEAK TEST

A leak test ensures that there are no gas leaks prior to lighting

your grill.

WHEN A LEAK TEST MUST BE PERFORMED:

• Before lighting your grill for the first time.

• Every time the propane cylinder is refilled

• If any gas component is changed

• At a minimum once per season.

• After prolonged period of storage or non-use.

• If the regulator flow-limiting device has been activated.

The leak test should be performed in a well-ventilated area

away from any open flame, heat or ignition sources. DO NOT

USE A MATCH, OPEN FLAME OR SMOKE DURING LEAK

TESTING.

WHAT YOU’LL NEED

FOR TESTING:

1. A mixture of 50% liquid dish

soap and 50% water.

2. A brush or cloth to apply

the mixture.

AREAS TO TEST ON PROPANE GRILLS:

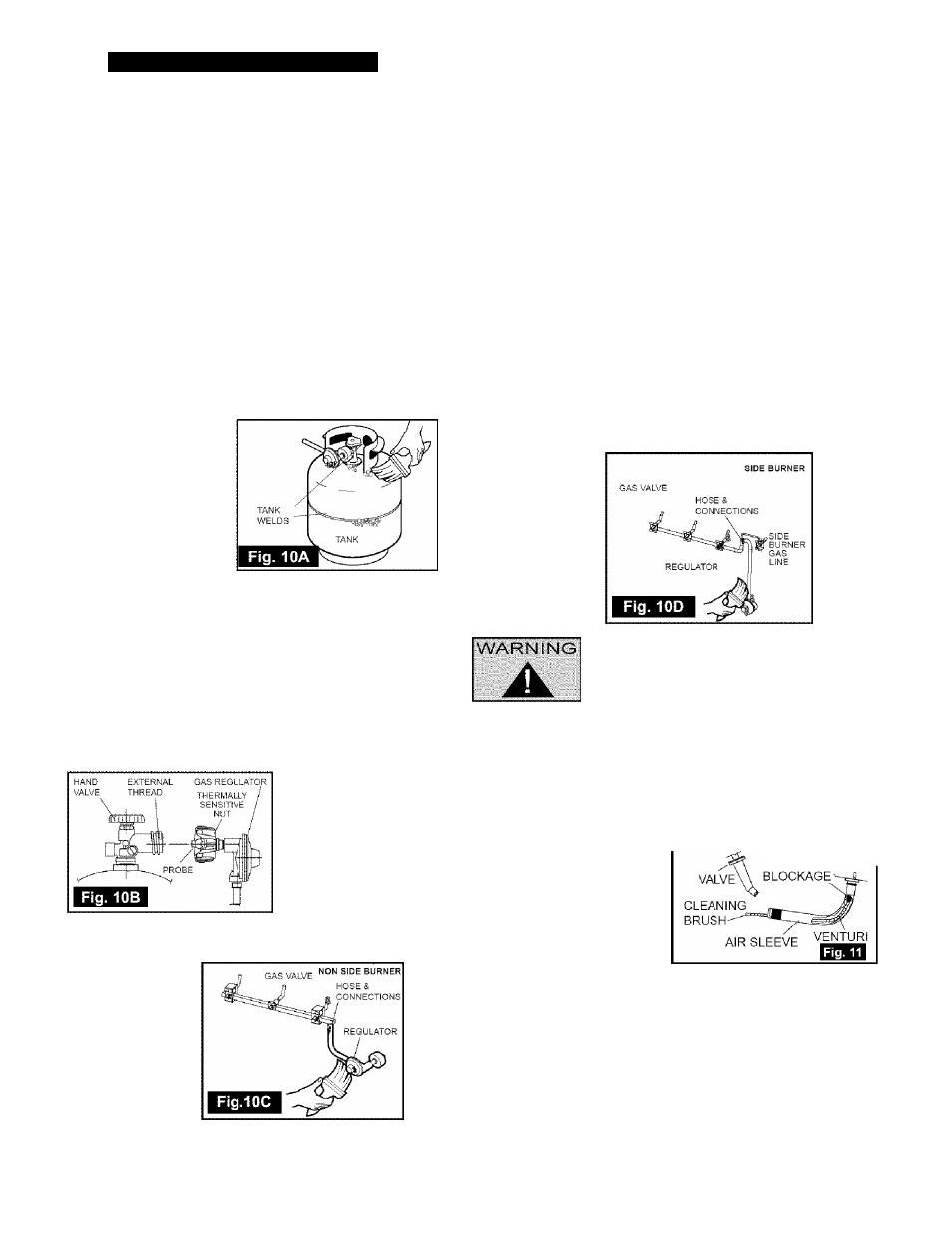

• All propane cylinder welds (see Figure 10A)

• Propane cylinder valve — including threads into cylinder

(see Figure 10B)

• Regulator fitting and propane cylinder connection

(see Figure 10B)

•All hose connections (see Figure 10C) including side burner

tubing, if equipped (see Figure 10D)

• All valve connections

(see Figure 10C & 10D)

AREAS TO TEST ON NATURAL GAS GRILLS:

• All hose connections

(see Figure 10C)

• All valve connections

(see Figure 10C & 10D)

HOW TO DO THE TESTING:

IWith the grill console control knobs in the ‘OFF’ position, twist

the valve on your propane cylinder 1 turn, or the main natural

gas valve on. DO NOT IGNITE THE BURNERS WHILE

PERFORMING THE LEAK CHECK.

2. Brush your soap and water solution on all connections and

components as outlined above.

3. Observe each place for growing bubbles, which indicate that a

leak is present.

4. Shut off the flow of gas while fixing the leak. Tighten

any leaking connection and repeat test until no leaks are

detected.

5. If the leak(s) cannot be stopped DO NOT USE Shut off the

fuel source at the valve immediately (if appropriate, remove

propane cylinder). Call a certified gas appliance service person,

or a gas dealer for proper repairs.

Failure to ensure the above may result in a

hazardous fire or explosion causing serious

bodily injury and/or property damage.

CLEANING VENTURI TUBES

Periodic cleaning of the venturi tubes is recommended for

optimum burner performance, especially after prolonged storage

or a period of non-use.

CHECK TO

ensure

the

burner

HAS A GOOD FLAME EACH TIME

IT IS TURNED ON.

How to Clean:

• Remove the burner

(refer to ‘ASSEMBLY

PROCEDURE’)

• Use a venturi cieaning

brush, bottle brush or

stiff wire and insert

into the venturi tube

approximately 1 inch at a

time, removing after each

inch to prevent pushing any debris further into the tube,

(see Figure 11)

• As you remove the brush head inspect and discard any

debris

• Continue this procedure until the entire lengths of all venturi

tubes are free of debris

• Reinstall burner (as per assembly instructions), ensure the

venturi tubes are seated over the valve orifices

(see Figure 1)

• Perform a Leak Test.

27