Carl Goldberg GBGA1089 User Manual

Page 8

8

5.

With the servo in place, remount both stabiliz-

ers and make a mark at a 90º degree angle to

the elevator hinge line, and in line with the

servo arm.

Position the control horn bolt so that it is 3/4”

back from hinge line on the mark that you just

made.

6.

Using a 9/64" drill bit, make a hole in the ele-

vator through to the top side.

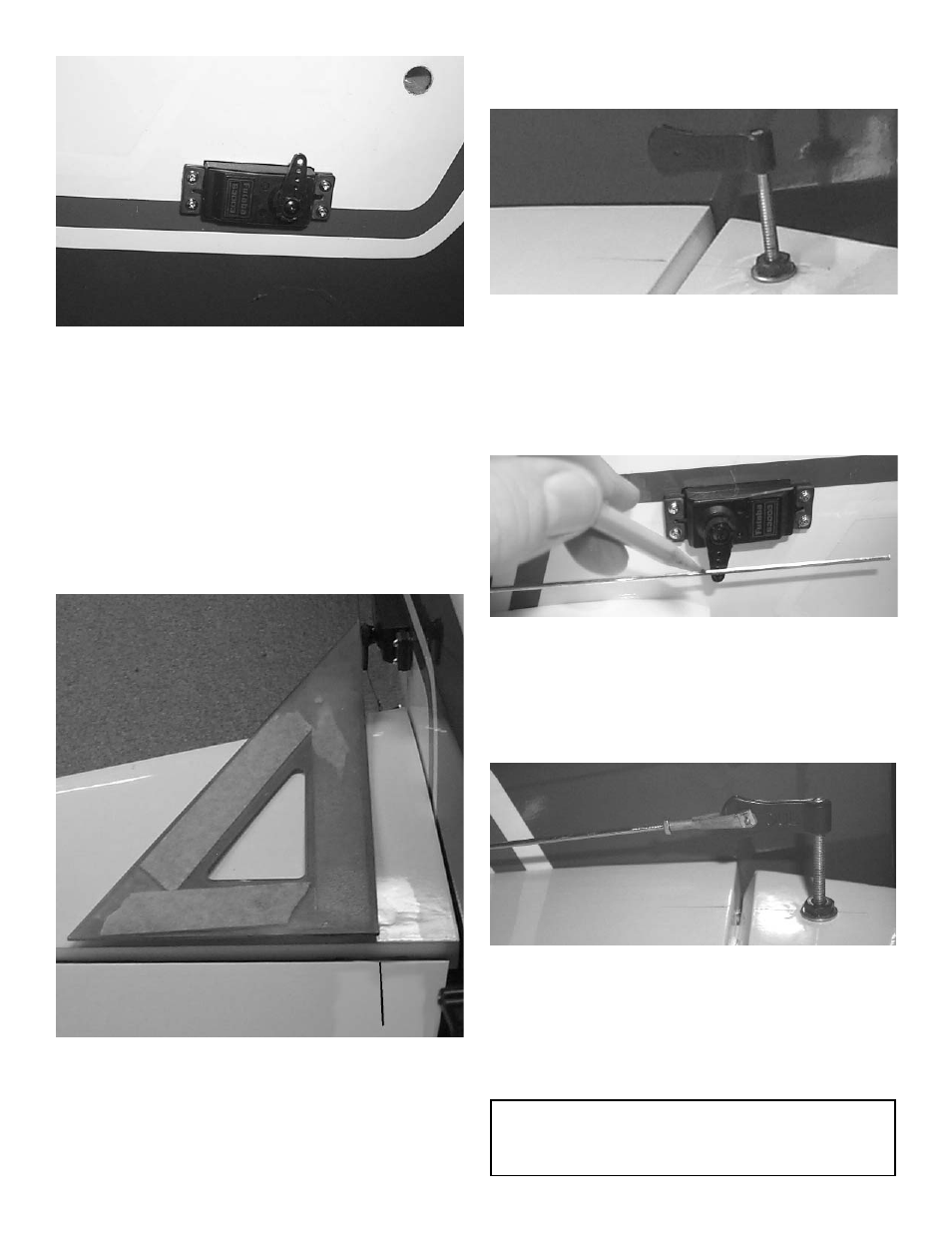

3.

At the rear of the fuselage just below the front

of the stabilizer you will find the servo cut outs

on both sides of the fuselage. The top cut out

is for the elevator servos.

Remove the covering over top of the elevator

servo hole

Mount your elevator servo with a 24” servo

extension taped to it.

4.

Pull the servo extensions towards the front of

the plane.

Repeat these steps for the second elevator

servo.

5.

Insert the 6-32 x 2” screw from the top through

the elevator.

Place the #6 washer and the 6-32 hex nut on

the bolt and tighten. Make sure that you use

thread lock on the bolt and nut.

Screw the black adjustable horn bracket on

the bolt.

6.

Thread the 2-56 hex nut and metal clevis onto

the end of the 2-56 x 7-7/8 pushrod.

Mount the pushrod onto the elevator control

horn.

7.

Keeping the elevator level, make a mark

where the pushrod touches the servo arm.

8.

Make a 90 degree bend at the mark you just

made.

Put the pushrod through the servo arm hole

and attach the swivel keeper.

Place a clives clip on each clevis.

Repeat for the other elevator.

Caution:

Make sure each snap link is fully closed with a

clevis clip before and after each flight.