Caution – Carrier AQUAFORCE 30XA080-500 User Manual

Page 41

41

RIGGING UNIT (See Fig. 16-18) — The 30XA080-500 units

are designed for overhead rigging and it is important that this

method be used. Holes are provided in frame base channels,

marked for rigging (see rigging label on unit). Field-supplied

shackles are required to facilitate lifting. Secure the shackles

to the base rails at the points noted on the rigging label. See

Table 2 for the number of lifting points for each unit.

Do not use a forklift truck to move the units.

Use spreader bars to keep cables or chains clear of unit sides.

As further protection plywood sheets may be placed against

sides of unit, behind cables or chains. Run cables or chains to a

central suspension point so that angle from horizontal is not less

than 45 degrees. Raise and set unit down carefully.

See Fig. 16-18 for rigging centers of gravity.

For shipping, some domestic units and all export units are

mounted on a wooden skid under entire base of unit. Skid can

be removed before unit is moved to installation site. Lift the

unit from above to remove skid. See Fig. 16-18 for rigging

center of gravity. On export units, the top skid can be used as

the spreader bars. If the unit was shipped with a shipping bag,

the bag must be removed to gain access to the rigging holes in

the base rail.

If overhead rigging is not available, the unit can be moved

on rollers or dragged. When unit is moved on rollers, the unit

skid, if equipped, must be removed. To lift the unit, use jacks at

the rigging points. Use a minimum number of rollers to distrib-

ute the load such that the rollers are no more than 6 ft (1.8 m)

apart. If the unit is to be dragged, lift the unit as described

above, and place unit on a pad. Apply moving force to the pad,

and not the unit. When in its final location, raise the unit and

remove the pad. If the unit was shipped with coil protection, it

must be removed before start-up. The shipping bag for export

units must be removed before start-up.

Step 3 — Cooler Fluid and Drain Piping Con-

nections —

See Fig. 19-22 for piping applications.

GENERAL — The factory-installed victaulic connections al-

low clamp-on connection of water lines to the coolers in all

30XA units. A flow sensor is factory-installed in the side of the

entering fluid nozzle. See Fig. 23. See Table 3 for 30XA unit

operating range. See Fig. 20 for cooler option dimensions.

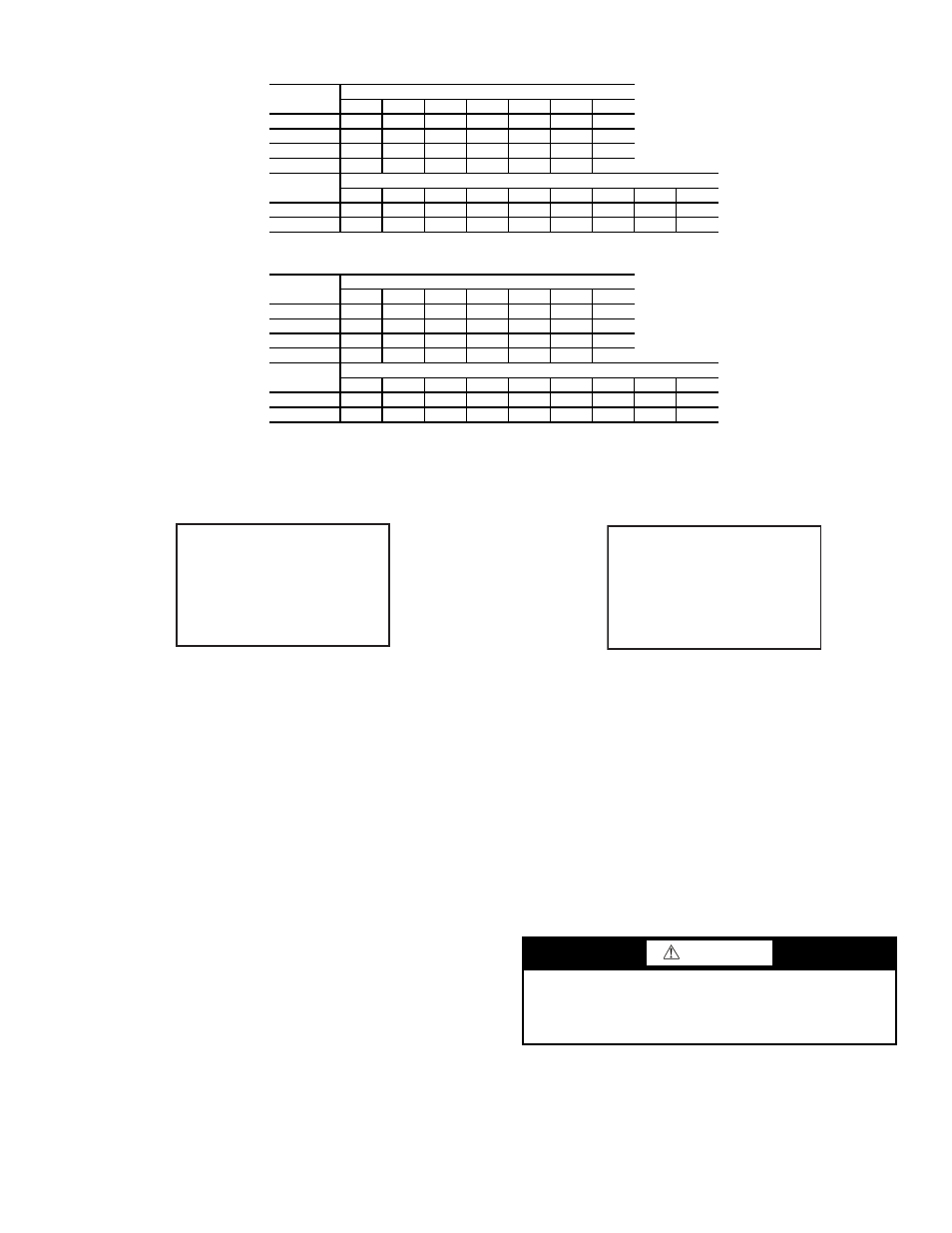

DUAL PUMP UNITS — ENGLISH

DUAL PUMP UNITS — SI

*Condenser Coil: Copper Fins/Copper Tubing.

30XA

UNIT SIZE

MOUNTING WEIGHT (lb) — Cu/Cu*

A

B

C

D

E

F

Total

090

1394

3347

1369

1093

2330

1392

10,924

100

1420

3409

1406

1117

2382

1418

11,151

110

1433

3452

1428

1139

2416

1424

11,291

120

1467

3491

1430

1142

2449

1458

11,436

30XA

UNIT SIZE

MOUNTING WEIGHT (lb) — Cu/Cu*

A

B

C

D

E

F

G

H

Total

140

2188

1735

2012

1889

1273

1004

1876

1990

13,966

160

2242

1762

2029

1919

1299

1019

1896

2043

14,209

30XA

UNIT SIZE

MOUNTING WEIGHT (kg) — Cu/Cu*

A

B

C

D

E

F

Total

090

632

1518

621

496

1057

631

4955

100

644

1546

638

507

1080

643

5058

110

650

1566

648

517

1096

646

5122

120

665

1583

649

518

1111

661

5187

30XA

UNIT SIZE

MOUNTING WEIGHT (kg) — Cu/Cu*

A

B

C

D

E

F

G

H

Total

140

992

787

913

857

577

455

851

903

6335

160

1017

799

921

871

589

462

860

927

6445

30XA090-120

30XA140,160

Fig. 15C — Unit Mounting Weights (Units with Cu/Cu Condenser Coils) (cont)

a30-4420

a30-4421

A

B

C

F

E

D

COOLER SIDE

COMPRESSOR SIDE

A

B

C

D

H

G

F

E

COOLER SIDE

COMPRESSOR SIDE

CAUTION

Remove the chilled water flow switch, entering and leaving

water thermistors before welding connecting piping. Rein-

stall flow switch and thermistors after welding is complete.

Failure to remove these devices may cause unit damage.