Troubleshooting – AERCO BMK 3.0 LN Nat. Gas for Mass. only User Manual

Page 69

TROUBLESHOOTING

8-11

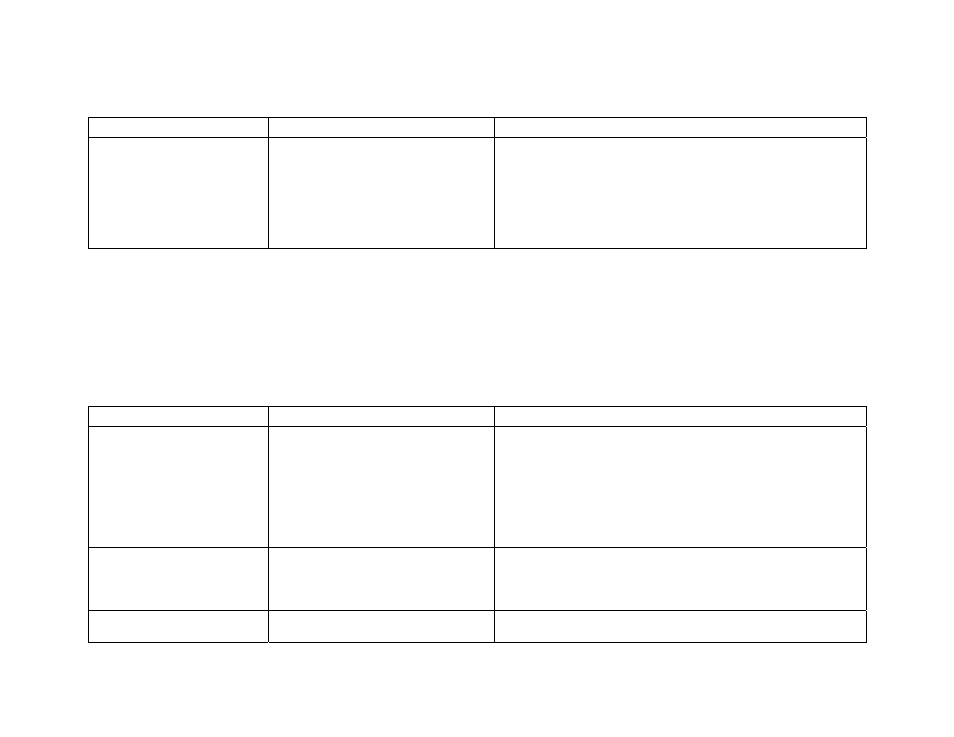

TABLE 8-1. BOILER TROUBLESHOOTING – Continued

FAULT INDICATION

PROBABLE CAUSES

CORRECTIVE ACTION

(continued)

4.

Defective Air/Fuel Valve stepper

motor.

5. Defective Power Supply Board or

fuse

6. Defective IGST Board

4. Replace stepper motor.

5. Check DS1 & DS2 LEDs on Power Supply Board. If they are not

steady ON, replace Power Supply Board.

6. Check “Heartbeat” LED DS1 and verify it is blinking ON & OFF

every second. If not, replace IGST Board.

8.2 ADDITIONAL FAULTS WITHOUT SPECIFIC FAULT MESSAGES

Refer to Table 8-2 to troubleshoot faults which may occur without a specific fault message being displayed.

TABLE 8-2. BOILER TROUBLESHOOTING WITH NO FAULT MESSAGE DISPLAYED

OBSERVED INCIDENT

PROBABLE CAUSES

CORRECTIVE ACTION

Hard Light-Off

1. Staged Ignition Ball Valve closed.

2. Clogged/damaged Gas Injector

(Figure 8-2).

3. Defective Staged Ignition Solenoid

(Figure 8-2)

1. Open the 1/4” Ball Valve downstream of the SSOV (Fig. 8-1).

2. Remove and inspect Gas Injector to ensure it is not clogged or

damaged.

3. Close the 2” and the 1/4” Ball Valve downstream of the SSOV

(Fig. 8-1). Start the unit and listen for a “clicking” sound that the

Staged Ignition Solenoid makes during Ignition Trial. If “clicking”

sound is not heard after 2 or 3 attempts, replace the Staged

Ignition Solenoid.

Fluctuating Gas Pressure

1. Gas pressure going into unit is

fluctuating.

2. Damping Orifice not installed.

1. Stabilize gas pressure going into unit. If necessary, troubleshoot

Building Supply Regulator.

2. Check to ensure that the Damping Orifice is installed in the

SSOV/Droop Eliminator Actuator (Figure 8-3).

Air/Fuel Valve “hunting” at 80%

Firing Rate

1. IGST and Power Supply Boards in

Control Box are outdated.

1. Check to ensure that the IGST and Power Supply Boards are

Rev. E or higher.