Chapter 1: modbus connection, 1 modbus configuration, 2 modbus functionality – AERCO AM Series Boiler Modbus Interface Manual User Manual

Page 5: Am series modbus interface manual

AM Series Modbus Interface Manual

CHAPTER 1: MODBUS CONNECTION

1.1 MODBUS CONFIGURATION

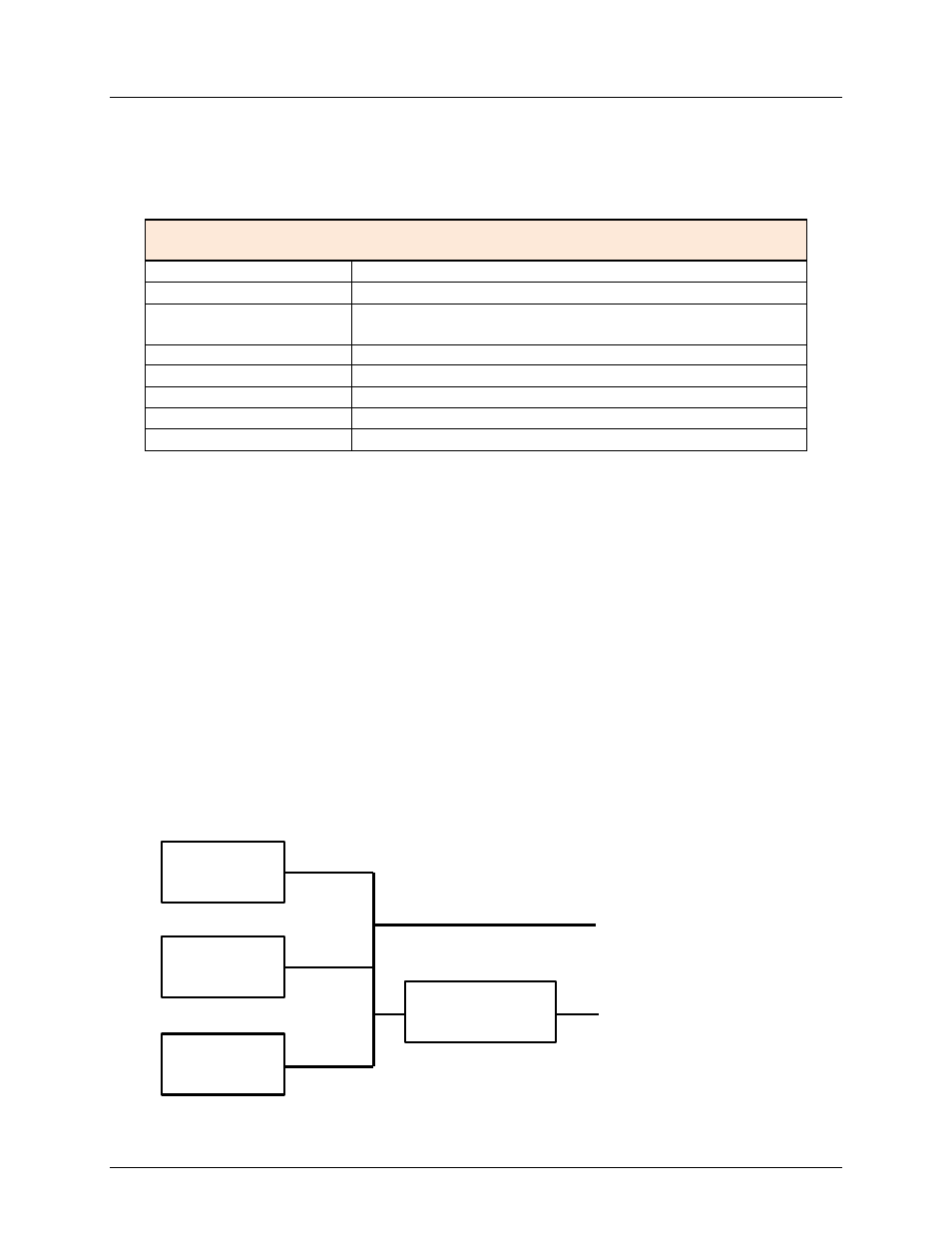

The table below summarizes the Modbus configuration details.

Modbus Configuration

Protocol

Modbus RTU

Default slave address

0x01 (settable with LabVision or by dll)

Supported Modbus

commands

Read Holding registers (0x03) Write single holding

register (0x06)

Baud rate

9600bps

Data Length

8

Parity

None

Stop Bits

2

Physical layer

RS485 (two wire + optional GND)

The default setting for the Modbus (dependent) address is 1. The address setting resides in the

e2prom of the interface and can be changed if required. This can be done using LabVision, via

the Argus link connection, or by dll.

Multiple holding registers can be read (up to all of the available registers for the device), writing

of holding registers is limited to one register at a time.

1.2 MODBUS FUNCTIONALITY

The basic modbus functionality gives control over the devices connected by their modbus

interface. The control includes building management systems, remote displays, and PLC control.

On installation, all AM Series devices must be set at a unique modbus address. To connect to

networks other than modbus, bus converters can be connected to the system. The optional bus

converter can then scans these addresses for active devices, and map them on the network it

needs to convert to. The AERCO ProtoNode Gateway can be used for conversion to BACnet,

LonWorks, Metasys N2, and Modbus TCP protocols. For further information, see the

ProtoNode Gateway user manual, GF-129.

IF

IF

XXX

Converter

(Optional)

Modbus Network

PC, or other

network BACnet,

LonWorks,

OMM-0102_0A

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913

Page 5 of

18

GF-146-MB

Phone: 800-526-0288

PRI: 09/22/2014