Carrier 4-WAY MULTIPOISE FIXED-CAPACITY DIRECT-VENT CONDENSING GAS FURNACE 58MXA User Manual

Page 8

10. Replace main furnace door.

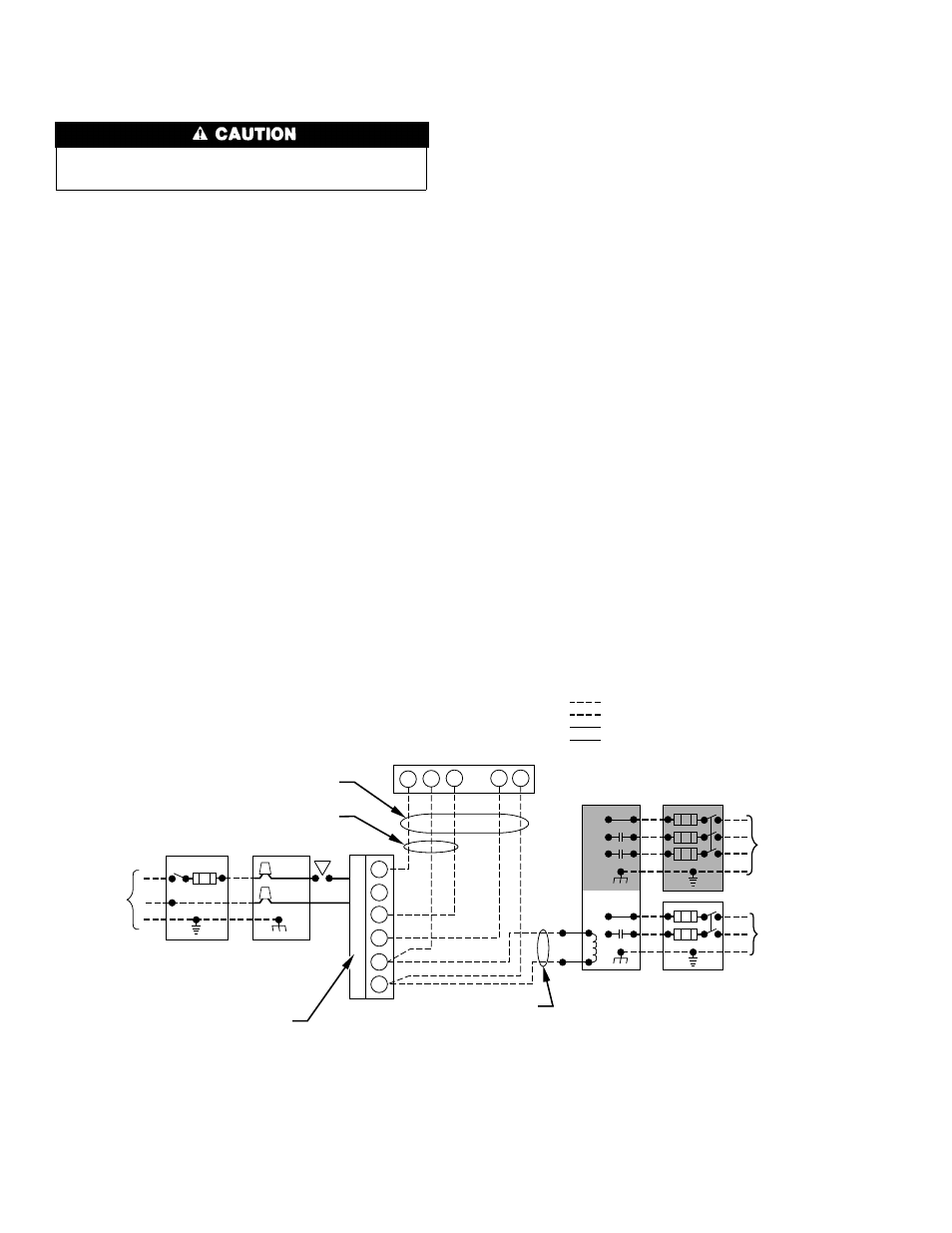

Step 7—Electrical Controls and Wiring

There may be more than 1 electrical supply to the unit. Check

accessories and cooling unit for additional electrical supplies.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig. 11 for field wiring information

and to Fig. 15 for unit wiring information.

NOTE:

If the polarity is not correct, the STATUS LED on the

control center will flash rapidly and prevent the furnace from

operating. The control system also requires an earth ground for

proper operation of the control center and flame sensing.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the control center. (See Fig. 12.) Any direct shorts of the 24-v

wiring during installation, service, or maintenance will cause this

fuse to blow. If fuse replacement is required, use ONLY a fuse of

identical size.

With power to the unit disconnected, check all electrical connec-

tions for tightness. Tighten all screws on electrical connections. If

any smoky or burned connections are found, disassemble the

connection, clean all parts, strip wire, and reassemble properly and

securely.

Reconnect electrical supply to unit and observe unit through 1

complete operating cycle. Electrical controls are difficult to check

without proper instrumentation; if there are any discrepancies in

the operating cycle, contact your dealer and request service.

Step 8—Troubleshooting

For an explanation of status codes, refer to service label located on

back of main furnace door or Fig. 16, and the Troubleshooting

Guide.

The control center stores 1 status code (representing the last fault

to occur) for a period of 48 hr or until the 115- or 24-v power is

interrupted.

NOTE:

Removing blower access panel will open blower access

panel door switch and terminate 115-v power to control center.

The status code will be erased. Look into blower access panel sight

glass for current LED status BEFORE removing blower access

panel.

The unit’s component test is a useful troubleshooting tool since it

displays the current status code of the furnace and functionally

operates all furnace components except the gas valve. The com-

ponent test and methods to initiate it are described below.

COMPONENT TEST SEQUENCE

NOTE:

All components are functionally operated except the gas

valve.

When component test is initiated, the following sequence of events

occurs:

1. LED flashes a status code 4 times.

2. Inducer motor starts and continues to run for remainder of

component test.

3. Hot surface ignitor is energized for 15 sec, then de-energized.

4. Main blower operates at cooling speed for 10 sec, then turns

off.

5. Main blower operates at heating speed for 10 sec, then turns

off.

6. Inducer motor stops.

Component test can be initiated by one of the following proce-

dures.

INITIATING COMPONENT TEST AND RETRIEVING STA-

TUS CODE BY REMOVING MAIN LIMIT SWITCH WIRE

NOTE:

NO thermostat signal may be present at control center

and all blower time delay off periods must be completed.

Fig. 11—Field Wiring

A98325

115-V

FIELD-SUPPLIED

DISCONNECT

SWITCH

115-V

SINGLE

PHASE

AUXILIARY

J-BOX

FURNACE

CONTROL

CENTER

TWO WIRE

24-V

TERMINAL

BLOCK

THREE-WIRE

HEATING

ONLY

FIVE

WIRE

NOTE 5

NOTE 1

NOTE

3

THERMOSTAT

TERMINALS

FIELD-SUPPLIED

DISCONNECT

CONDENSING

UNIT

R

W2

W

C

R

G

Y

GND

GND

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-, 208/230-, 460-V WIRING

208/230- OR

460-V

THREE PHASE

208/230-V

SINGLE

PHASE

W/W1

Y/Y2

G

C

NOTES:

1.

2.

3.

4.

5.

Connect Y or Y/Y2 terminal as shown for proper cooling operation.

Proper polarity must be maintained for 115-v wiring.

Use W2 with 2-stage thermostat when zoning.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

Some thermostats require a "C" terminal connection as shown.

8