4 | compressor assembly – GEA Bock FK20 User Manual

Page 12

12

09740-09.2013-DGbFIT

r

D

GB

F

I

TR

4| Compressor assembly

4.3 V-belt drive

4.4 Main bearing load

4.5 Electromagnetic clutch assembly

ATTENTION! Inappropriately designed belt drives, especially belt knocking

or excessive tensioning forces can cause compressor damage!

Make sure that the drive belt is designed correctly, e.g. by using

tensioners and selecting the belt profile and the belt length.

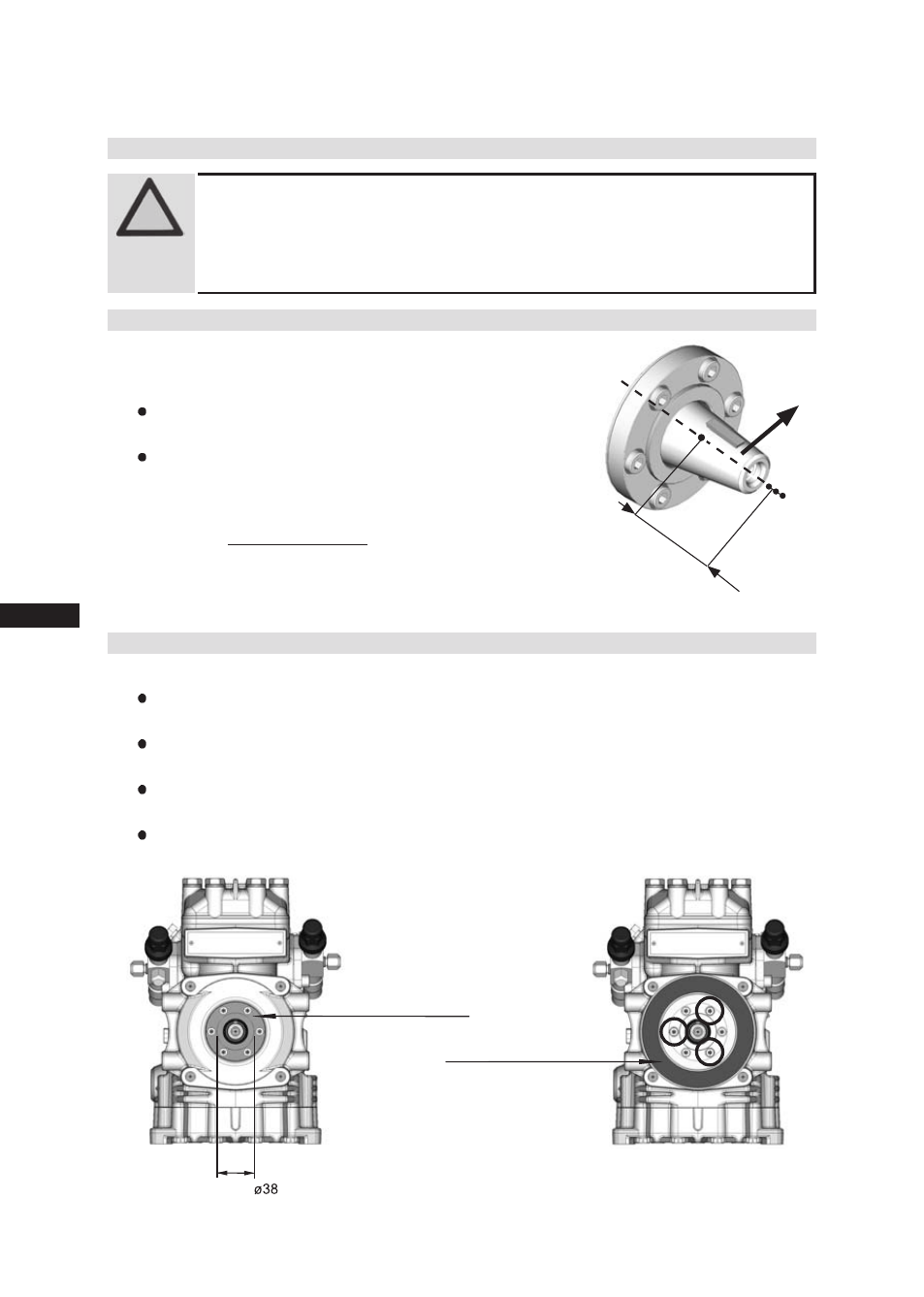

The following description applies for an electromagnetic clutch secured to a shaft.

To absorb the magnetic field of the electromagnetic clutch, the sliding ring lid has

a snug fit Ø 38 h8 (see Fig. 10).

To connect the magnetic field, remove the marked Allen head screws of the sliding ring lid

(see Fig. 11).

Slide the magnetic field to a snug-fit and fasten using the three M5 x 18 cheese head

screws provided (Fig. 11). Screw torque = 9 Nm.

Further assembly of the electromagnetic clutch according to the clutch manufacturer.

Fig. 10

Sliding ring lid

Magnetic field

Fig. 11

To prevent the belt drive overloading the compressor main bearing,

ensure that:

The engagement force applied by the belt tension (see Fig. 9)

must not exceed F

max per.

= 600 N.

If the force engagement point shifts to the right (see Fig. 9,

small point), the force F

max per.

reduces as per the following

formula:

F

max per.

= 30 kNmm

(50 mm + L

1

[mm])

F

max=

600 N

M

bmax=

30kNmm

L

1

(mm)

Fig. 9

Snug fit